DIY hair clipper repair

A hair clipper is an indispensable tool for both professional masters and “home hairdressers“. These devices for a hairstyle differ on household and professional. But those and others, sooner or later fail. Typically, this unit is repaired by electrician repairmen, for example, in a household. But some malfunctions of the machines can be fixed by hand. Before you start the search for breakdowns, if your tool does not work well, you need to have an idea about the internal structure of this machine for cutting.

Content

Hair clipper device

There are 2 types of units for haircuts, which differ in the principle of action.

Rotary

This type of clippers is the most expensive hairdressing power tool on the market and is available in two versions: mains powered devices and cordless tools. Rotary machines are distinguished by their reliability, high power and durability. The main driving element of this unit is the electric motor, on the rotor of which an eccentric is worn. When rotating, the eccentric connected to the movable knife moves it in different directions. Also in the apparatus there is a knife block consisting of a fixed part and a movable part.

In the standalone version in the instrument case are accumulator battery (Battery) and control board.

Vibrating

This is a budget option for power tools for hairdressers than discussed above. In this machine instead of an electric motor coil installed. In front of the coil is a pendulum containing a permanent magnet.When current passes through a coil, the polarity of the magnetic field at a frequency of 50 Hz changes on its core. Therefore, a permanent magnet in the pendulum changes its position all the time, and since the latter is connected to a movable knife, it starts to move. Also in the device you can watch the power button.

Main malfunctions

Search for breakages in devices for cutting can differ, depending on their design features.

Rotary device faults:

- breakage in the head of the nozzle;

- electric motor failure;

- breakage of the control button;

- problems with the network wire;

- eccentric wear.

Battery failures:

- battery life has expired or is faulty;

- power supply failed;

- problems with the cord coming from the power supply unit to the device;

- control board burned out;

- mechanical failures in the knife block.

Vibration machine faults:

- breakage of the coil winding;

- loud noise;

- network cable defective;

- power button breakage.

In addition to all the problems listed above, there are breakdowns that are inherent in all types of hair clippers: the tool does not cut at all, cuts badly, with gaps, pulls or chews hair.

Troubleshooting algorithm

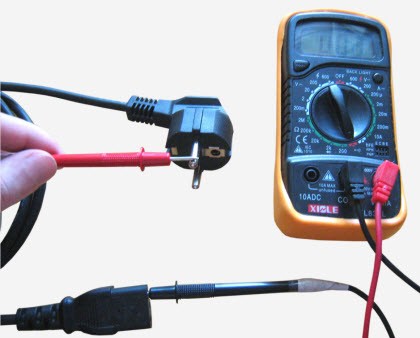

First of all, if your hair clipper does not turn on, it is necessary to check the presence of voltage in the outlet, as well as checking the power cord and plug. The voltage in the outlet is checked very simply: plug any electrical appliance into this outlet. If it works, then there is tension. Next, you need to check the plug: if it is collapsible, then you need to unwind it and make sure that there is a good contact of the wire with the plug pins. If it is not collapsible, you will have to disassemble the unit and ring both wires with a tester.

A frequent reason for why the machine does not work may be a faulty power button. In addition, you should make sure that the wires are not soldered from its contacts.

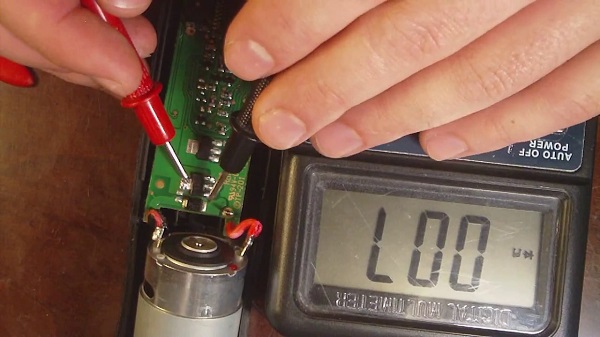

In the case where the button, wire and plug are in order, check that the contacts inside the device that went to the motor or to the coil are not soldered off. If problems with contacts are not found, then you will need to ring the windings of an electric motor or coil.

If it stopped working rechargeable hair clipper, then first of all the power supply is checked. Next, you need to check the battery inside the unit.In the case of a non-working battery, it will have to be replaced with a new one, since the repair of the battery will not work. If the power supply and battery are OK, then the control board (if available) is called.

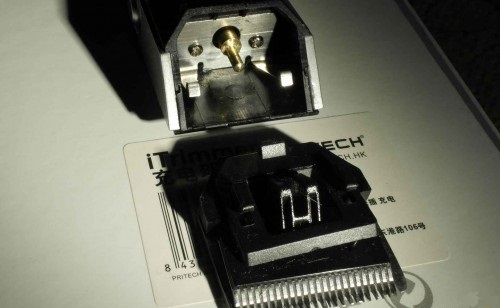

In case of malfunctions caused by mechanical damage internal parts of the device, the electrical part of the unit will start. Therefore, damage is sought in the head where the knives are located, or in the block where vibrations are created. This may be a problem with the eccentric (in inexpensive models it is made of plastic, it quickly wears out), or a pendulum breaks at its junction with a movable knife.

If you notice that the device is chewing or pulling hair while cutting, causing inconvenience, then it's time to take care knife sharpening. This procedure is best left to a specialist who has special equipment for these purposes. Attempts to self-sharpen knives usually lead to the fact that they have to throw away. If the machine stopped cutting, you will need knives adjustment.

How to fix the tool yourself

DIY repair of the hair clipper is quite possible with some faults, the elimination of which does not require special knowledge and skills.At home, you can make the following repairs.

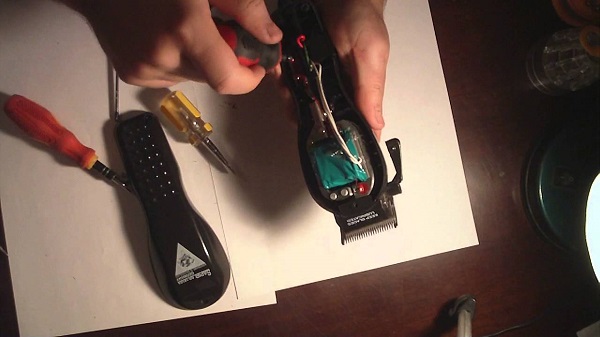

Rotary machine does not start, the lights are on

This problem sometimes occurs when blockage of motor or eccentric rotor. At the same time their wedges, the motor heats up and may buzz slightly. It is necessary to disassemble the body of the unit and clean the rotor with the eccentric from dirt, then assemble the device and try to turn it on again. Also, if the device falls, then in this case there may be a power failure, which is fed to the motor. It is necessary to open the case and check the soldering in the places where the conductors are connected. If the wires are disconnected, solder them.

The machine does not start, the lights are off

Perhaps the cause of the breakdown may be in the power cord or electrical plug. In the case of a battery device, the problem may be hiding in faulty wire or in the power supply. It must be disassembled, check all contacts and ring the coil windings with a tester for the presence of an open circuit or interturn circuit. If you detect these problems in the coil, the power supply will have to be replaced with a new one.

Vibration machine buzzing heavily

This problem may occur when voltage drops in the network. Therefore, in some devices there is a special regulator with which you can set the optimal operation of the device. Also, increased noise may appear when case damage, for example, after the fall of the unit. It is necessary to open the case and check it for cracks, and how tightly the coil holds. When the power tool was dropped, the coil fasteners could break, so there is a strong vibration and noise. Sometimes the screws holding the coil may spontaneously loosen. In this case, they must be tightened without exerting excessive effort, otherwise you can break the seat of the screw, and it will start to roll.

/rating_on.png)

/rating_off.png)