The principle of operation of various programmers for the washing machine

The programmer used for washing machines is an important element of the control circuit, which is responsible for the choice of operating mode. This is one of the most important components that distinguishes automatic machines from conventional ones.

Content

Types of programmers

AT automatic washing machines a variety of wash programsthat take into account the type of fabric, the degree of contamination, the speed and type of washing, rinsing and spinning. Each of these processes has its own operating temperature, spin speed, wash duration and other parameters. Performing these tasks and provides this control, receiving signals from sensors, installed in the schema. Programmers are of the following types:

- hybrid;

- electronic.

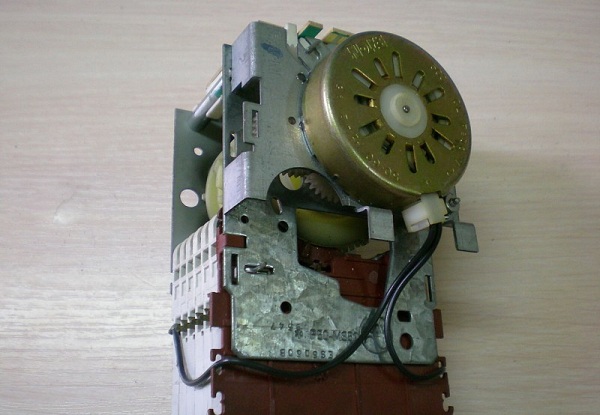

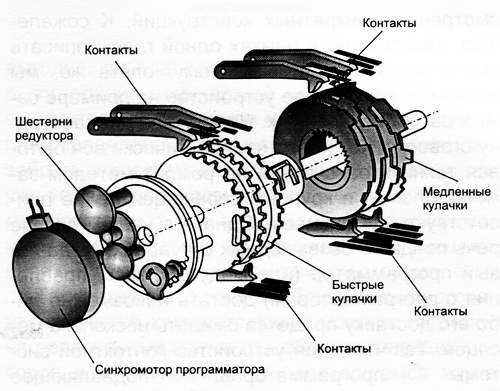

Hybrid include a set of software drives with a synchronous motor and gearbox. Electronic composed of microelectronics assembled on a specific board. Consider the device of each of them in more detail.

Hybrid programmer for Bocsh washing machine

Design and principle of operation

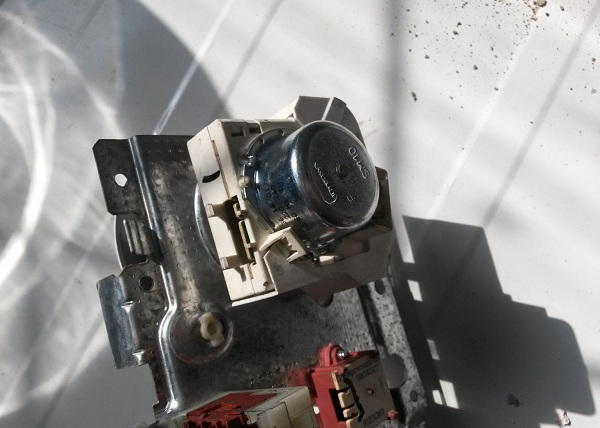

Hybrid programmer - This is a complex element of the washing machine, which may have a different design depending on manufacturer's companybut the same principle of action. In devices of this type, the synchromotor rotates the program disks on which the protrusions and depressions, called cams, are made. During rotation, the cams interact with the pusher arms, which in turn switch the actuator contacts of the programmer. The rotation speed of the synchromotor lowers the gearbox. The cams have different control functions: for example, “fast cams” are responsible for reversing the drive motor of the washing machine (switching the direction of its rotation), and “slow cams” are responsible for switching the washing modes.

The device programmer washing machine

Electronic programmer, As a rule, it consists of several electronic elements that are responsible for various parameters and commands:

- power supply of the device;

- temperature conditions;

- water level control;

- engine management;

- control valves and other elements of the system;

- protection of system elements.

The principle of operation is based on the formation of an electrical signal in the controller in accordance with the specified parameters and the transfer of this signal to the devices for its execution and control.

Hybrid programmers are considered more reliable than electronic, because the latter are more sensitive to the quality of the supply voltage of the device (voltage surges). In addition, they are much more expensive, but they have an important advantage - this is a greater number of functions and a more accurate tincture of the mode of operation.

Replacing and repairing programmers

When such an important element of the control circuit as a programmer of a washing machine fails, the question always arises: which way to go: contact a specialized organization or repair it yourself? With the first option, it is less of a hassle, but it is more expensive; with the second, you can save money, but you will have to work.

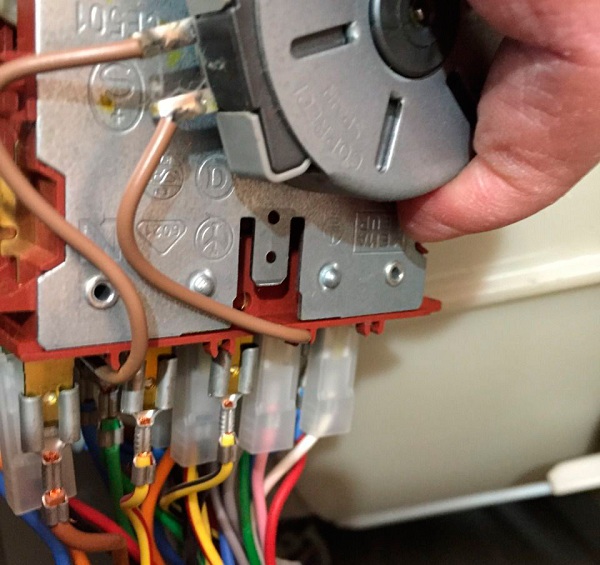

If the washing machine is equipped with an electromechanical programmer, then you need to purchase a new one of similar design and install it in place of the failed one. In case you need to change the electronic one, there is much more work, and for this you need:

- purchase a branded programmer;

- download drivers for the purchased device;

- download firmware for a specific model;

- install everything on the computer and check the equipment operability;

- connect the programmer to the control panel of the washing machine and to the computer;

- install the program and drivers on the programmer, execute the firmware.

It should be noted that it is better to purchase a proprietary programmer - it has already been tested at the factory, it is easier to connect it, and to find software for it.

Currently, each manufacturer of washing machines produces components for them, so you can always choose the right spare part for a particular brand. Spare parts are sold from representatives of firms, in repair and service services, in online stores.

/rating_off.png)