How to connect a water heater

To provide the dwelling with hot water, many methods are used: gas water heaters, flow-through and storage boilers. If it is impossible to use a gas column for any reason, then the choice of a boiler remains an alternative option. Moreover, it is easy to connect such a water heater with your own hands.

Content

Types of water heaters

Before connecting the water heater, it should be noted that the units are divided into flow and accumulative. The design of flow-through installed powerful heating elements that provide rapid heating of the fluid flowing past them.

Storage water heaters have capacities of different sizes. To keep the temperature in the tank, it has good thermal insulation. Storage boilers can be divided by type:

- direct heating;

- indirect heating;

- combined.

Direct heating boiler

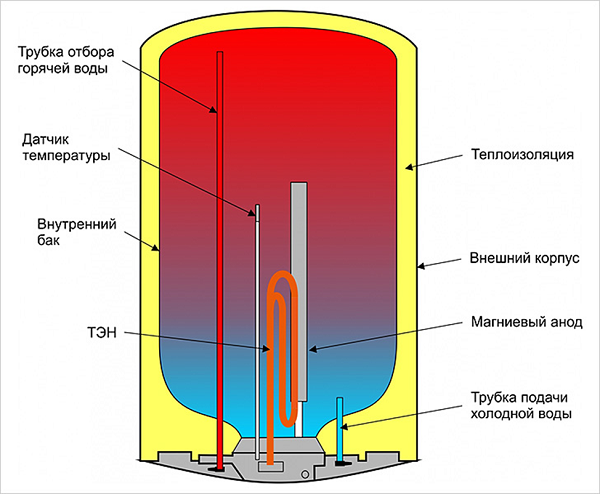

In devices of this type inside the tank are the heating elements that provide heating fluid. When the boiler has already been connected to the water supply, cold water is supplied from the bottom, and the already heated one comes out through the top of the tank.

Fluid temperature is controlled by a thermal sensor. Units can be designed for vertical mountingas well as horizontal.

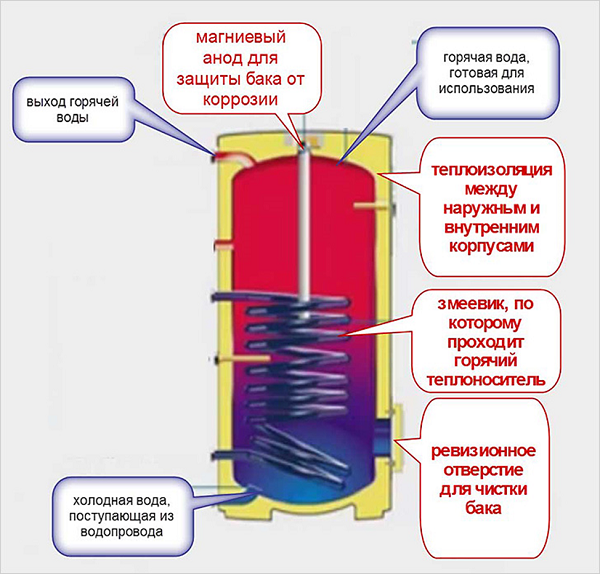

Indirect heating boiler

Devices of indirect heating work together with any heat carrier: a heating system or a solar system (solar panels). By design, the device resembles a direct heating device, but the only difference is that there are no heaters. Heating of the fluid occurs due to hot water in the heating system circulating in the heat exchanger.How to connect an indirect heating boiler will be considered further.

Combined devices

The device turns into a combined water heater when the heating elements are inserted into it (holes in the tank for mounting the heaters can be provided in the tank). This unit is convenient to use in the summer when the heating is turned off or when there is not enough power produced by the heating circuit.

Connection of accumulative boiler

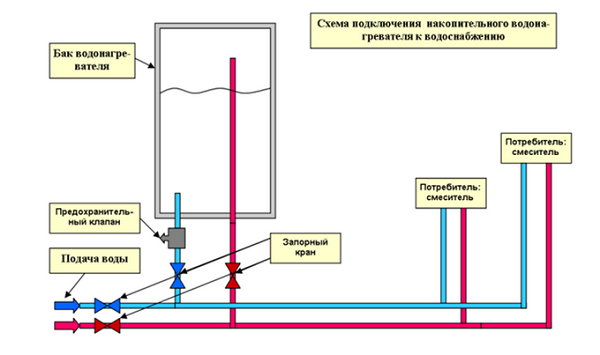

For the supply and removal of fluid at the bottom of the heater (accumulative) installed fittings. The nozzle for hot water is marked in red, the blue one for cold. It is recommended to use polypropylene pipes that provide a reliable connection.

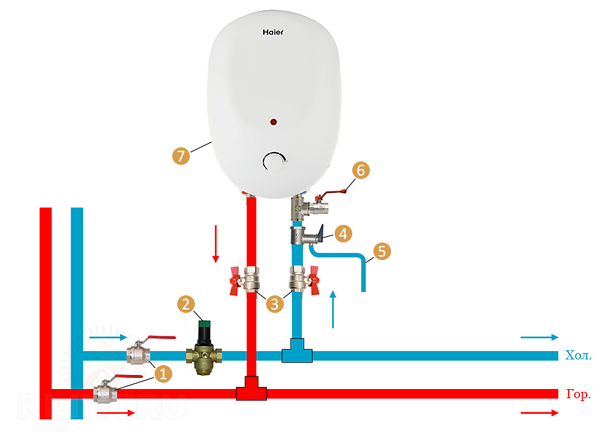

The figure below shows the simplest and most reliable scheme of connecting the water heater to the water supply.

The following rules should be observed:

- it should be possible to shut off the water supply to the dwelling with the help of valves;

- the branches leading to the unit must have shut-off valves;

- if poor quality water is supplied to the highway, installation, after a stopcock, of a water filter is necessary;

- between the entrance to the tank and the safety valve requires the installation of a drain valve,allows you to quickly drain the water from the tank if you need to repair or maintain the device;

- Before connecting the storage water heater to the water supply, it is necessary to acquire in advance various types of fittings, T-branches (tees) of flexible and rigid connecting pipes.

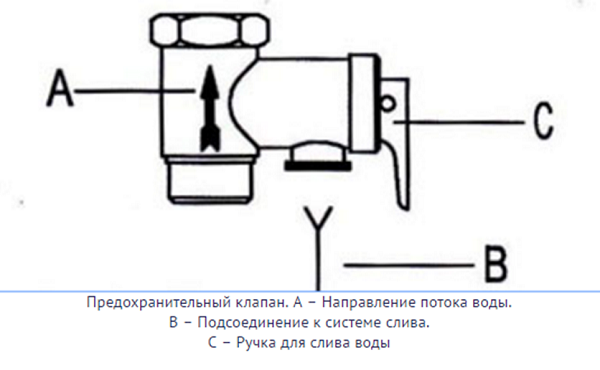

In addition, the connection of the storage water heater requires the installation of a safety group of two valves. Safety mounted to protect the tank from overpressure. If it rises to a critical level, the valve opens and fluid is discharged through the drainage hose to the sewer or special tank. Back the valve does not allow water to flow out of the tank when the pressure in the line drops or is absent. Thus, it prevents the drainage of heating elements, their overheating and burnout.

The connection diagram of the water heater (boiler) to the water supply is shown in the figure:

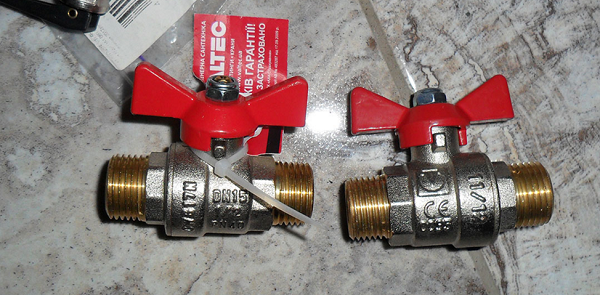

A set of parts for connecting the device to the water supply may vary depending on the material of the main water pipes.

With iron or steel pipes

How to connect the boiler to the water supply,if in the apartment (house) the highway is carried out with use of standard iron pipes? You can use the modern method of connection, without the use of welding (welding adapter with thread). In this case, used adapter "vampire" which is a completed hole and thread clamp.

Adapter "vampire"

The installation of the clamp is very simple, and is carried out in this way:

- place on the riser is required to pre-clean paint and rust;

- the clamp must be placed on the riser using rubber gaskets and tighten the bolts to fix it;

- shut off the water supply and drain the rest by opening any mixer tap;

- drill a pipe through the hole in the clamp using an electric drill;

- Further, having wound the crane, it is possible to start connection of the required elements.

With metal pipes

Connection of a water heater to such a conduit is the simplest. Metal-plastic bends easily, and various types are used to connect elements. crimp fittings.

Connection steps:

- cut a pipe of the required size;

- then you will need to carefully select the place for the tie-in, while taking into account the size of the tee with minus the part of the pipe that will go into the connection;

- for cutting a small area you can use special scissors;

- it is necessary to remove the nuts from the tee and put them on the 2 ends of the pipe together with the fixing rings;

- flare the ends of metal-plastic using a special calibrator or screwdriver;

- insert the tee until it stops, after which you need to move the rings and tighten the nuts with a key.

There are also fittings for metal pipes, which require pressure testing (compression). In this case, you will need additional special tools.

With polypropylene pipes

Before you connect the boiler to the water supply using polypropylene pipes, you need to prepare: soldering iron for soldering plastic water lines, scissors for cutting it, a pair of tees and adapters for the thread that is located on the valves and the emergency valve, as well as the number of angles necessary for the design. Further:

- the place of connection is selected;

- in the pipe is cut a section equal to the width of the tee, minus 2 centimeters (1 cm will go on each side of the tee);

- using a soldering iron, it is necessary to heat the pipe and fitting to the desired state and connect them (you cannot turn them during the connection, as this may break the tightness);

- using segments of a conduit of different lengths and corners, liner is made to the nozzles of the unit;

- A threaded coupling is soldered to the end of the water conduit, after which the whole structure is securely connected.

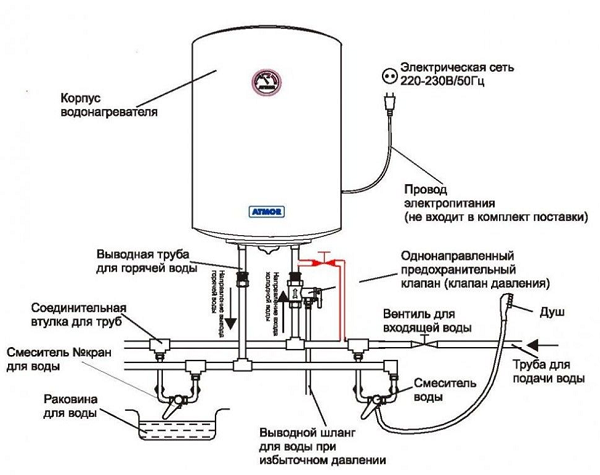

Step-by-step connection of all elements

Regardless of which water lines will be used in an apartment or house, the connection scheme of the storage unit and the algorithm for connecting all the elements will be the same.

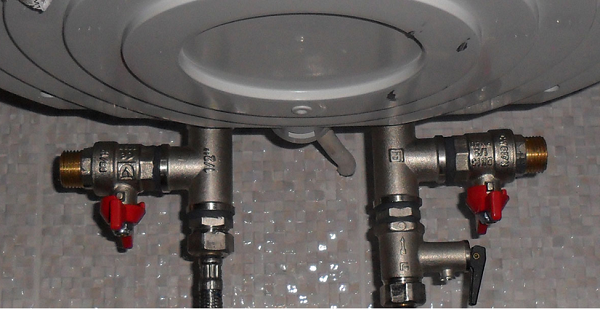

- Flax is wound on the pipes located at the bottom of the tank to seal the connection.

- After that, with the help of a wrench, tees are screwed onto the pipes.

- Next, the taps are screwed into the installed tees. These taps are used to drain the fluid. When the right-hand faucet is open, water from the apparatus will flow up to a certain point, after which the drain will stop. If you open the left - the air will begin to leak and the drain will continue.

- After placing the valves, installation is required. safety valve on the tee through which the liquid will be supplied.

- On the water line through which hot water will go out, it is installed shut-off valve (3).

- It now remains to make the connection of cold water, and the wiring for hot to the right rooms (in the case of installing the device in a private house). For an apartment, a pipe through which heated water comes out of the tank is connected to the main conduit with hot water. In the absence of heated water in the line, you can use the unit (in this case it is necessary to shut off the hot water supply valve (1) to the apartment). If the flow is resumed, then shut off valve (3) on the hot water pipe coming out of the apparatus is closed.

The connection diagram of the cumulative boiler to the water supply system is shown in the figure:

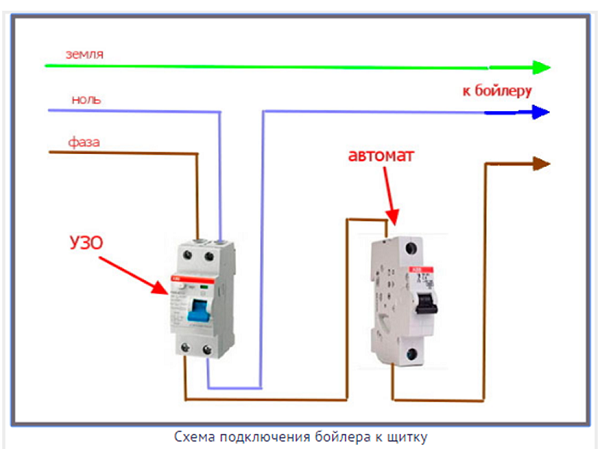

Electricity connection

It is not recommended to turn on the device in a regular outlet. This type of connection to the electrical network cannot be considered safe and can cause a fire. And yet, how to connect the water heater? Connection of the boiler to the home power supply network should be made through a separately extended line from the panel. Line is equipped circuit breakerwhile the power of the machine must be at least 16A. The factory wire is disconnected from the heater and a new one is connected. three-core cable (copper), having a cross section of 2.5 mm.

Apparatus required must be grounded. Otherwise, when bathing in the shower, a slight tingling of the current and other troubles are possible, up to and including the wiring and fire breakdown. Grounding is connected to the distribution board. If you do not understand this, invite an electrician.

Next, do the following:

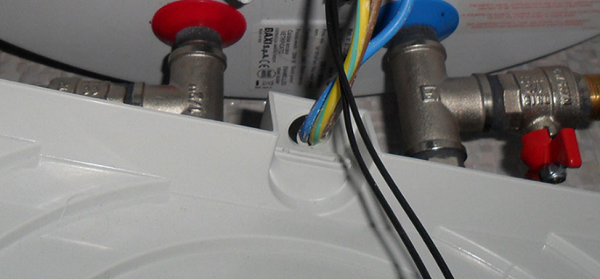

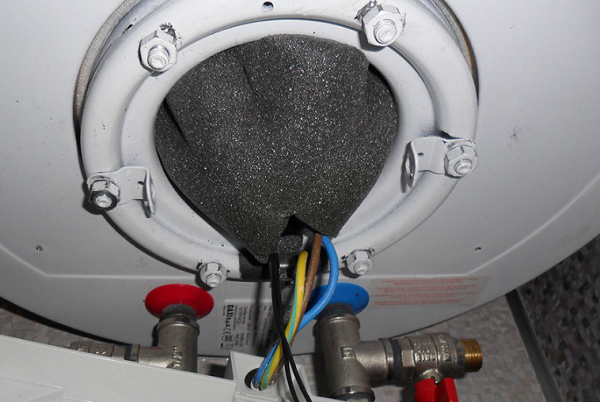

- Cut the cable to the desired length and pass it through the hole in the bottom cap of the tank.

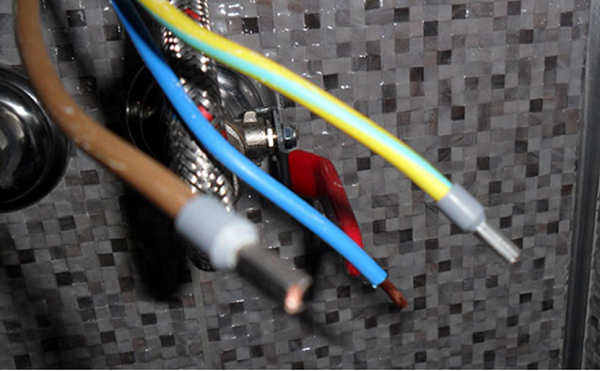

- Using a knife, clean the ends of the wires from insulation.

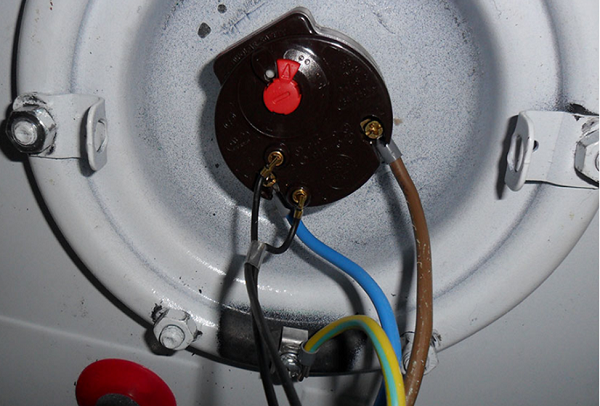

- Connect the wires to the machine. The yellow-green wire is grounding, and is screwed to the unit housing. The rest (brown and blue) are screwed to the contacts of the thermostat. The contacts on the thermostat are marked, so where to connect the zero, and where the phase, will not cause difficulties.

- In conclusion, heat insulation is put in place (if any), and all this is buried with a lid.

Connection of indirect heating boiler

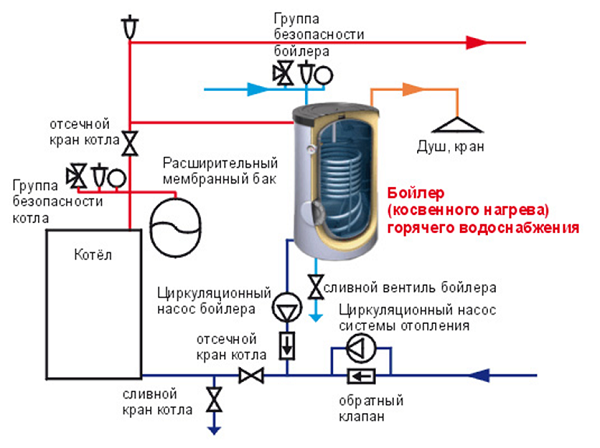

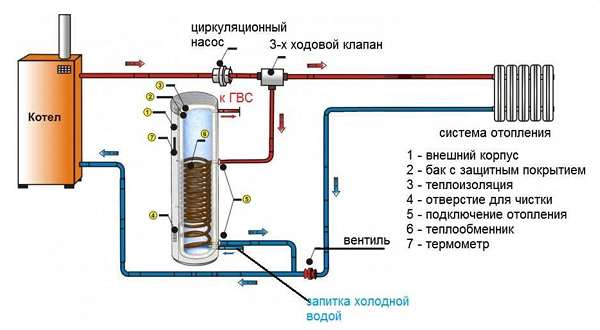

The device of indirect heating does not have its own source of heat, but uses energy of heat from other sources (central heating, gas or solid fuel boiler, etc.).Therefore, for each source, an individual scheme for connecting an indirect heating boiler is selected.

R heating system

In the apparatus with indirect heating is available harnesswhich is connected to the water supply and heating circuit. It is necessary to adhere to the following rules:

- cold water must be supplied through the bottom of the tank;

- the output of the heated fluid through the top of the unit;

- there should be a recycling point in the middle;

- The heat carrier must be connected in such a way that it starts moving through the top of the heat exchanger and out through its lower branch pipe - thanks to this movement, the maximum efficiency of the device is achieved.

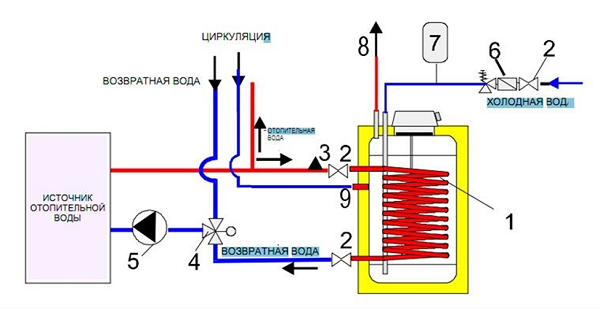

With three way valve

Such connection of the indirect heating boiler is realized if there is circulation pump. As can be seen in the figure, the heating circuit and the unit is connected in parallel, and a three-way valve (controlled by a temperature sensor located in the housing of the apparatus) is mounted after the pump.

The valve is connected to the unit by one of its outputs.A tee is inserted into the return pipe in front of the boiler, to which the outlet of the heat exchanger is connected. At this sidebar in the heating system can be considered complete.

The principle of the scheme

When the temperature sensor receives information that the temperature of the liquid in the tank is lower than the set one, the valve switches the flow of coolant to the unit and the heating system is turned off. Thus, the redirection of the entire flow of heat carrier through the heat exchanger contributes to the rapid heating of the liquid. When the liquid has been heated sufficiently, the valve will again direct the flow to the heating circuit.

This boiler connection scheme can also be used to connect to a double-circuit boiler.

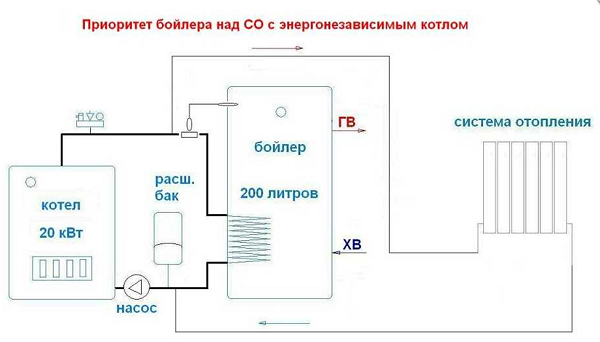

R non-volatile system

With the existing scheme in which the boiler is non-volatile, it is recommended to place the device higher level radiators. With this arrangement, the circulation of the coolant will occur due to gravitational forces. Although, it is also possible to integrate a pump into this scheme, but there will be no heated water when the power is turned off.

With this type of connection, it is necessary that the water conduit going to the unit has a cross-section diameter greater by 1 step than that used for heating. Due to this, priority is achieved.

Recycled

The recirculation unit allows instant hot water to the consumer. This is convenient in that it does not require draining cool liquid until the hot one begins to flow. This feature is provided by an installed pump to maintain circulation in looped loop. This system is called recycling. This design often includes a towel dryer.

In the recycling system in the strapping apparatus is used:

- non-return valve that prevents mixing of heated and cold water flows;

- air duct - his task is to prevent the ingress of air during the pump on;

- safety valve - relieves pressure in emergency situations;

- expansion tank, designed to compensate for the expansion of the heat carrier, while the pressure in the tank should not rise above the triggering level of the protective valve.

Thus, if you connect the water heater according to all the rules, it will allow the units to work in the correct mode and provide the consumer with hot water.

/rating_off.png)