What are the differences between radial and axial fans

The climatic equipment is widely used in the industry and life. Depending on the purpose and conditions of the installation of ventilation unit is selected. There are centrifugal and axial devices. Both those, and others set in motion air masses, but with a different orientation, power and pressure. Let us consider in more detail what the difference is between radial fans and axial units.

Content

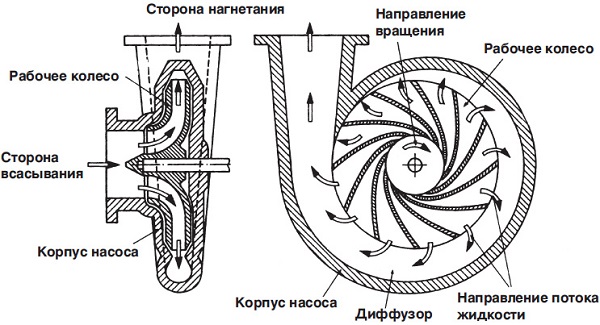

The principle of operation of the centrifugal device

The design of the radial fan consists of a wheel with rotational vanes, suction and injection mechanisms. Under the influence centrifugal force from the periphery, air is drawn into the center, and pushed out perpendicular to the incoming air flow into the external environment.This principle of operation of the device allows its use in underground tunnels.

The blades in the wheel may be parallel or perpendicular to the axis of the circle. Using the first option allows you to reduce noise without losing performance. The second type allows you to make the design more compact, but with less power, which also finds its application.

Models can be equipped additional systemsdepending on which industry it was developed for. For example, in devices the protection against high temperatures can stand, and the construction itself is made of a heat-resistant material that is resistant to corrosion. A protective function for explosion may also be incorporated. These capabilities can be combined in one device, but can be found in separately.

The radial device is capable of serving extended main canals, since due to the creation of high pressure it quickly moves large volumes of air masses.

Axial fan mechanism

Axial fan differs from radial in uncomplicated design and low cost. The mechanism consists of a through cylindrical ring, inside of which are located at an angle of the blade. This arrangement of internal parts allows the screw to trap air and disperse it in space.

Despite the simple mechanism, the device is very effective. Significant mode changes during fan operation have a negligible effect on the engine load. There is no such advantage in radial devices. The axial fan due to the reversibility can change the direction of propagation of the air flow when the working position of the wheel changes.

The absence of centrifugal force in the device does not allow to create a lot of pressure. If there is a need to increase the flow of air, the design is complemented by steps and the frequency of rotation of the blades, but this will increase the noise in the ventilation system.

How to make a choice between devices

In most cases, the choice of ventilating device dictates the area of its application. As practice shows, the radial fan is more used in industry, the axial unit is actively used in the installation of the ventilation system in rooms,used as an engine (motor) cooling in household appliances and transport.

Radial fan in the paint shop

The main factors on which the choice of fan model is based are as follows:

- ventilated air volume;

- the shape of the duct and its area;

- length of the ventilation system;

- maximum and minimum level of expected air temperature.

The separation of the use of mechanisms associated with the work of the air vent. The difference of the axial device is the distribution of air flow from the axis into space around the circumference. A radial fan, on the contrary, creates the direction of air from the perimeter of a circle and directs it to the center. It can be said that the difference between these two devices in their design and air recirculation.

Given the scope, there may be a need for air flow. high pressure. For complex industrial installations, radial fans are more suitable. Axial devices are more oriented to work in places for simple and quick airing.

Axial industrial fans

When creating a supply and exhaust ventilation system are also used channel fans. They can act as a self-installation inside the air vent or an additional link in the ventilation mechanism.

This device is compact and easy to install by hand, has a low noise level.

To ensure forced air circulation, a specific mechanism is selected that is capable of providing it. Technical parameters must comply with the requirements of the installation of ventilation for certain conditions.

/rating_off.png)