Which walker is better to buy

It is difficult to imagine a modern suburban area that does not need regular tillage. To alleviate this difficult work, modern industry has developed and implemented several improvised devices at once, one of which is a walk-behind tractor. With the onset of spring, warming and preparation for sowing works, it is time for increased interest in these devices. About which walker is better to buy, and what are the features of different types of walkers, consider next.

Content

Opportunities and scope of the motorblock

To figure out how to choose a good walker for garden and garden, you need to figure out what is this device. This unit is Simplified tractor with a small power reserve. Of course, the size of the device is much smaller than that of a conventional tractor, because the motor-block has to work in much closer conditions: on garden beds, where standard-sized machinery cannot even drive in.

Another important difference is the principle of the axial device. The unit operates on a single axis.

The main tasks that the motoblock is intended to solve usually fit into the list of agricultural works: plowing, harrowing, loosening, digging, etc. It was for use in the backyard environment was designed and assembled walk-behind tractor. The capabilities of the unit can be limited only by the number of attachments with which it interacts. Most often, the instrument is used to treat the surface of a site in one form or another.

- Plowing. Any easy motor-block for the house will cope with this task. As a rule, a special device, so-called, is responsible for the process.plow If the scale goes beyond the garden or plot, then the mounted plow is attached to the tractor. The motoblock favorably differs from analogs in the degree of immersion in the soil: the plow penetrates deeper. Due to deeper immersion, more intensive mixing of the soil components occurs, it is better saturated with oxygen.

- Hilling. Hinged hiller helps to handle the potato field with the help of the motoblock. Mechanical hilling is much faster and more productive manual. Hilling largely saturates the tubers with oxygen and helps evaporate excess moisture. In addition, you can still pile up strawberries. This will be especially useful if the sown ridge grows in the territory under which the groundwater flows.

- Harrowing. For harrowing, you must use the appropriate type of attachments with special teeth. Basically, this feature is used for crushing large lumps of earth and loosening the crusts on the soil surface. In some cases, using the nozzle for harrowing can be removed part of weeds.

- Planting and Harvesting - Another convenient feature of the motorblock.As a rule, users resort to the services of potato planters and potato diggers. When the motoblock with the appropriate nozzles is involved in the work, the process is much faster - both in a small area and in an open field. Up to two and a half buckets of potatoes can be placed in an appropriate collection tray for tubers, and with the help of a sower it is allowed to plant onions with garlic.

- Haircut and care for decorative lawn. To implement this type of work it is necessary to choose a walk-behind tractor with a mower. However, today this type of equipment is included in most complete sets of all models. The grass is cut at a one meter distance around the device, which is much more effective than a trimmer. Such attachment equipment as an aerator, after the use of which the lawn begins to grow more crowded, without bald spots, belongs to the care of grass. A modern chopper is installed on modern tillers, thanks to which grass and tops are cut into compost. Another feature in the care of flowerbeds and lawns is a special motorized pump, with which it is easy and convenient to water the beds and flowers.

- Winter operation. Motoblock is a universal tool, so that its use is not limited strictly to the spring and summer period. If necessary, the device is well operated in the winter. To do this, a special snow removal shovel, snow dumper and corresponding brushes are installed on the device, which greatly facilitates manual labor.

- Transportation of small loads. Often, after working on the site, a lot of different wastes remain - this is both cut grass, and sawed branches, and household waste, and construction debris. If the owner of the motoblock has a small trailer, then he can safely collect all the garbage and effortlessly take him to a landfill. It is very convenient in cases when a small construction or repair work is planned, as well as after autumn and spring harvesting on the garden plot.

Of course, in order to realize all the listed possibilities of the motor-block, it is necessary to purchase each of the nozzles separately. The basic package of budget models in addition to the power unit includes only the wheels and the cultivator.

Do not forget that the greater the power of the tiller, the more functions it is able to perform.

Main differences of the motor-block from a cultivator

There are not so many differences, and those that can be called technical. By and large, the main difference between a motoblock and a cultivator is productivity, the amount of power it possesses. Based on this indicator, other parameters, weight, size, dimensions, etc. are also considered.

The cultivator was developed as a narrowly targeted device designed to prepare the soil before planting. As a result, this device has a lower productivity than the walker. In addition, the latter can "try on" a wide range of attachments, significantly expanding their functionality. It is because of the presence of a greater number of possibilities that the choice of users more often remains behind the walk-behind tractor.

Another significant difference is thrust principle. At the motor-block the draft is developed in wheels therefore the whole unit functions. The cultivator instead of wheels is equipped with the appropriate tool.

The cultivator can be mechanical, which is very convenient for use in a small garden 3-4 acres, where the walker can not turn around. A motoblock is always equipped with a power unit, without which its further operation is impossible.

Despite the differences, both the cultivator and the motoblock have a number of similar functions.The first device is more mobile and overall, but the walk-behind tractor is more versatile and productive, thanks to which it is in good demand among domestic consumers.

Classification of tillers by weight

Devices can be distinguished by two main points: by mass and performance, and by the fuel on which they operate. If we talk about the first paragraph, there are 3 main categories: light, medium and heavy aggregates.

Light

They have a light body, their power is measured in the range from 2 to 6 hp. The fuel injection system is a classic carburetor. The total weight ranges from 30 to 75 kg. The cooling system of the power unit is air, without the participation of antifreeze. This is usually hand tilleri.e. It is controlled, as they say, in the old fashioned way. The speed of moving around the site is usually only one, and you can immerse such a unit in the back of a car yourself or with the help of another person. With the help of a light motoblock, you can calmly, without unnecessary trouble, process the land plot area up to one hectare.

There is only one significant disadvantage of light tillers: few types of attachments can be attached to them. Most often on a lightweight unit using a passive root-cutter.

Average

Conventionally, devices with engine power from 6 to 12 hp fall into this category. Most of these models have water cooled diesel enginewhich is much more effective at intensive load on the power unit removes heat than passive air cooling. In addition, such devices are equipped with a full 2-3 speed gearbox, including reverse. The mass of the device, excluding attachments, is from 75 to 170 kg. This unit can be easily processed up to two hectares of land.

The middle class of tillers can use many different options for additional equipment: a plow, a milling cutter, a cultivator, a seeder or an automatic digger. If you need to trim the grass or water the lawn, it is possible to install a mower or sprayer-pump. In addition, the snowplow can be connected to the middle motoblock. If desired, attach a trailer to the device, and use its traction capabilities to transport cargo across the section.

Heavy

A heavy tiller has the following basic characteristics: its weight ranges from 170 to 300 kg, and the engine power is measured from 10 hp.In essence, models that weigh from 250 kg and have a capacity of 15 hp are miniature tractors, often with driver's seat. On such a device is installed 3-5 speed gearbox with reverse and differential, which can be blocked. The gearing potential ensures the availability of torque for the PTO shaft, and it, in turn, drives all the attachments. The principle of operation is similar to the older models of tractors. If the user has a wide range of additional tools that can be used, this type of instrument most of all the others falls under the definition universal walking tractor.

What type of fuel to choose

In this context, all tillers can be divided into three main categories.

- Electric. Most often this is a small type of motor-block. This unit can be processed at a time up to 5-7 acres of land. Most often used for loosening the soil in the greenhouse, where it is not possible to use the internal combustion engine. Can work both from a network, and from the rechargeable battery.

- Gas engine. They are equipped with models of medium and large sizes.As a rule, the internal combustion engine on gasoline is the 2nd and 4-stroke. The main criteria for selection are the engine size, measured in cubic cm and its power, measured in hp.

- Diesel. Most often it is a single-cylinder 4-stroke internal combustion engine mounted on a medium and heavy walk-behind tractor. Devices running on diesel, more environmentally friendly and economical. But the price of their service is much higher. In addition, the fuel system itself is much more sensitive to high-quality fuel, which can be difficult to find outside the city.

In some cases, there are alterations. Owners of some gasoline tillers adapt their devices to work on gas, which can lead to significant savings for fuel.

It is important to remember that reworking is possible only from a gasoline engine, diesel analogues have no such possibility, or adaptation will be quite problematic.

Select the type of gear

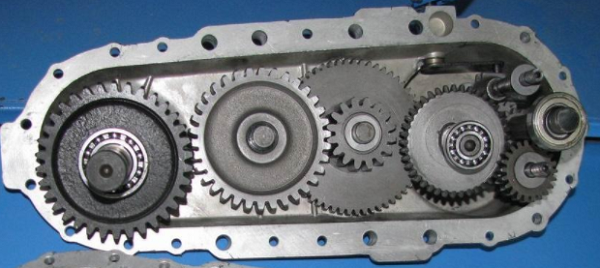

This node is one of the most important in the device. With it, the potential of torque is generated and transmitted. From what kind of gearbox installed in the device, will depend on the complexity of its operation and maintenance. In addition, different types of gearboxes make noise in different ways. Switching speeds also depends on which gearbox is installed in the system.

- Worm Gearbox. Usually installed on a single-stage gearbox, which can be found in the lightest models. The presence of a worm gear is good, because during operation even at elevated loads such a box produces much less noise. ICE, controlled by a worm gear, installed in the gearbox, works soft and smoothly, without jerks. A shortcoming is a short period of work: unfortunately, this type of gearbox wears out pretty quickly.

- Gearbox with chain mechanism. This type of gearbox is more reliable than the previous one. The chain reducer is installed mainly on tillers of the middle and heavy class. The axis of the engine is equipped with a leading sprocket, and the working shaft driven. Their connection is carried out using a conventional chain, which must be lubricated and tightened. In the event of a change in the gear ratio changes the force of the working tool. This is very convenient, because It is possible to choose the power that is required to perform all sorts of tasks.Chain gearboxes are found both collapsible and disposable. If a serviced type of reducer is installed on the model, then some of its parts (asterisk) can be easily replaced. A significant drawback of such gears is noisy work.

- Gearbox with gears. The principle of its work is based on a combination of gears of different sizes. Like the chain, gear reducer is installed on medium and heavy tillers. This gear box is considered the most durable and reliable. Gear gear copes well with increased loads, but it costs much more expensive. In addition, the repair gear reducer will also be expensive.

The choice is not as great as it may seem. However, you should not forget that what kind of gear is installed depends on the mass of the device itself. All light tillers are equipped with worm gearboxes. Medium and some heavy - chain. And only all heavy ones, which are, in fact, small all-wheel drive tractors, are equipped with gear reducers.

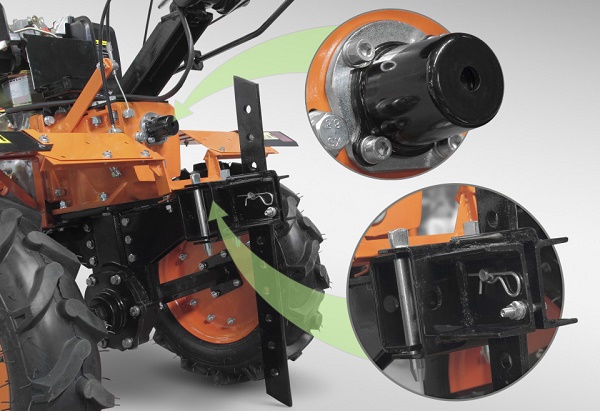

What is the grip

Clutch configuration depends on what task the unit will perform.In the classification of tillers there are several types of coupling.

- Friction clutch. The most common grip among gardeners and gardeners. Very easy to maintain in “field” conditions. Parts can be found in any relevant store, and the working life and payload indicators that this clutch can withstand are well above average.

- Centrifugal clutch type. Judging by the numerous reviews of users, this type of adhesion can slip in loose soil, as a result of which rather rapid wear of the surfaces with which contact occurs occurs. Not the most popular type of clutch.

- Hydraulics. It is necessary to press the accelerator pedal, and in the hydraulic clutch, the piston starts moving, which leads to the beginning of the movement of fluid through the central channel. From the pressure that has appeared in the system, the connecting rod comes into motion. It returns to its original position with the help of a spring system.

- Belt Coupling. The low popularity of this type of clutch is due to the fact that it wears out pretty quickly.Often there are belt breaks when working at high loads. The more powerful the engine mounted on the model, the faster the belt grip wears.

- The clutch disc type. Devices with disc clutch differ in the number of parts. There are single-disk and multi-plate clutch. The principle of operation remains the same, the difference lies in the increased comfort and reliability of the device. Disc clutch is one of the most reliable; on devices with such a device, the softest control is stated, as well as smooth and trouble-free starting of the power unit. The downside is expensive service.

Differences can be depending on the ignition system installed on the power unit. Here clutches are divided into permanently closed type and non-permanently closed.

Useful additional options

Below will be considered useful additions that facilitate the management of the device.

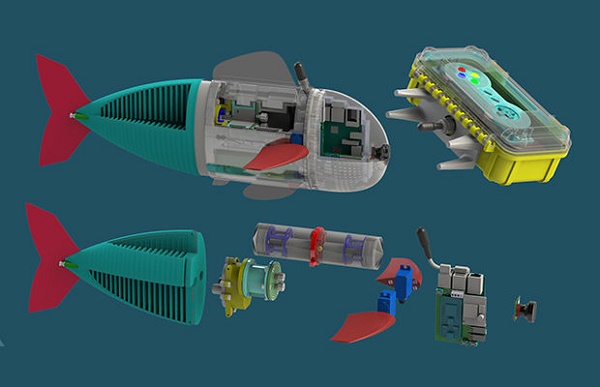

PTO

A very useful solution that significantly increases the functionality of the device. The power take-off shaft allows you to operate much more attachments and operate the motoblock in the winter, turning it into a snow blower. However, if the task of the unit does not include the need for plowing large areas, as well as high power, you can restrict yourself to a regular, light-weight tiller without a shaft.

Differential

Due to the presence of the differential, the walker becomes more maneuverablethat is very important on a small plot of land. The radius of turn of the wheelbase is significantly reduced, due to which blockages on the side when turning are practically excluded. In essence, the differential allows you to lock the wheel without applying physical effort. As a rule, models with this option are downshift in gearbox.

Of course, a motor block with a differential lock will cost much more, but a device with such capabilities will be much more useful and functional in home gardens.

Water cooling

In the warm season, the issue of cooling the engine is particularly acute. When operating at high loads for a long time, the power unit heats up quickly. For its cooling it is necessary to resort to additional manipulations, since the passive system often fails.Water cooling of the engine will help remove excess heat from the motor with much greater efficiency than the air cooling system. Water-cooled motorblocks are much more expensive, but in operation they are more preferable due to increased reliability.

The choice of the motor-block for different sites

Many experts recommend basing your choice on what soil composition in the working area and its area. If the soil is loose, the site is small, and a deep dive is not required, then we can limit ourselves to low-power models. The larger the plot, the density of loam and the need to dive for plowing, the more powerful the technique will be required for its processing.

In some cases, you should pay attention to landscape and its features: the presence of large stones, stumps and snags. If the site is hilly, and there are a lot of stumps on it, then the all-wheel-drive walk-behind tractor will simply have nowhere to turn, besides, due to irregularities, the efficiency of tillage of the land will significantly decrease.

The main criterion for selecting a device is still the area on which it is planned to perform work.The dependence here is direct: the larger the plot, the more powerful the tiller will be needed for its processing.

Conclusion

Modern tiller is a device-designer, which is subjected to all sorts of "modding", numerous alterations and changes in the original design. This makes the device even more functional and useful in home gardens. And the number of attachments offered by default is able to satisfy almost all basic agricultural needs. That is why for a fairly short time, the walker from the means of luxury has become the lot of wide user interest, going to the section of tools that are essential for every summer resident.

/rating_off.png)