Features of the device and the choice of the motor pump

A motor pump is a water pump that is installed above the level of the pumped liquid and is driven by an internal combustion engine or an electric motor. In normal operation, it is able to suck water from a certain depth and pump it out with a large flow rate to the height and distance determined by its technical characteristics. Unlike stationary units, it characterized by mobilitythat was the key to its widespread use in various sectors of economic activity.

Content

Scope of motor pumps

Pump pump is needed where you need to pump water from one tank to another, drain any water body or flooded area, send a large flow of fluid to where it was needed at the moment. It is used to:

- draining pits and ditches during construction;

- pumping out liquid during rescue and recovery operations by utility and rescue services;

- creating a reserve of water for technological and fire prevention purposes;

- extinguishing fires;

- irrigation of agricultural land or watering of garden and park plants.

Device and principle of operation

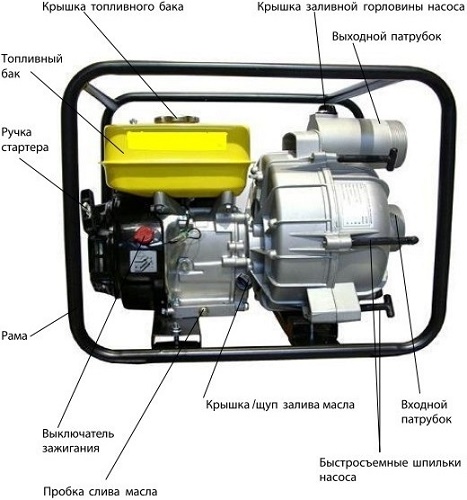

Motor pump for water is a centrifugal pump, combined with the engine into a single unit. To achieve maximum compactness, they are positioned coaxially or generally mounted on a common shaft. Most models have a rigid frame that serves as a stable support. It is convenient for carrying and engaging with lifting mechanisms. Heavy products can be installed on mobile platforms.

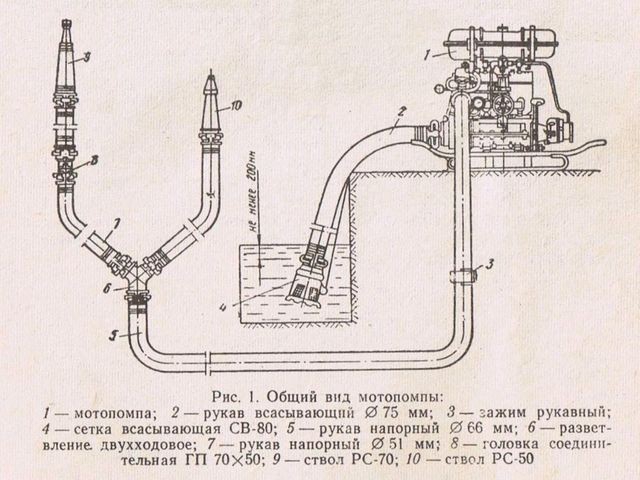

Pump pump has a robust hollow body with suction and discharge nozzles. Inside it on a rotating shaft is an impeller with blades.A suction hose with a check valve is connected to the receiving nipple, the other end of which is lowered into the reservoir or connected to the pumped tank. To eliminate the possibility of equipment clogging with algae, garbage and other mechanical objects, the suction hose is often equipped suction filter. For directional discharge of fluid, the discharge pipe is connected to a pressure hose or pipeline.

The principle of the motor pump is simple. When the engine starts, the impeller begins to rotate at high speed, pushing out the air there from the body. Due to the created dilution, the liquid is sucked to the pump intake and is released with excess pressure in the direction of pumping.

Motor pump classification by engine type

First of all, pumps differ in the type of engine installed. The most widespread units:

- petrol;

- diesel;

- gas;

- electric.

Portable gasoline pump is universal. With relatively small dimensions, it develops a sufficiently high power. It is easy to use and has full autonomy.Units with an electric starter are easy to start in all weather conditions and demonstrate stable performance.

A high-pressure fire engine with such a drive can be mounted on a wheeled chassis. It works reliably and will not fail in a critical situation.

Gas models in many respects similar to gasoline, only as a fuel using a liquid propane-butane mixture.

Diesel pump needed where high fluid flow is required. Such self-priming pumps are usually heavy. They are used as stationary or mounted on a trailer. They can be used as a source of high pressure for pumping water to great heights and long distances.

Electric pump extremely easy to operate, does not require special maintenance and frequent repairs. It can work in unventilated areas, pits and wells, where due to exhaust gases it is impossible to install equipment with an internal combustion engine. But the motor-pump with an electric motor has one major drawback: it cannot be used far from the landscaped areas with a reliable electric network.But in the urban utilities or at the dacha, it can be used with extreme intensity.

Classification by type of pumped liquid

Under field conditions, pumping equipment has to be used for pumping liquids with varying degrees of purity and the presence of solids. For heavily polluted water, a deviation from the normal level of acidity and an intense mechanical effect on pump parts are typical. Therefore, there was a kind of specialization of pumps, which are different in connection with this design features and material performance.

Conventionally, these pumps can be divided into several groups:

- for clean and slightly polluted water;

- for moderately polluted water;

- for dirty water.

The higher the degree of contamination and the largest falling inclusions, the greater the gaps are provided for in the device of the liquid path, and higher quality steel is required for the manufacture of parts.

For the mud mass, as well as for thick and viscous liquids of non-aqueous nature, except for centrifugal ones, they are also used diaphragm pumps. They do not have quickly rotating parts associated with the pumped medium, so they are less subject to wear.

Basic specifications and tips for choosing

The main technical characteristics of any pump are:

- volume flow rate measured in m3/ hour or l / min;

- maximum head, calculated in meters of a liquid column, overpressure atmospheres or MPa;

- suction depth, measured in meters.

To estimate the upcoming costs of operation and proper connection, it is also important to know:

- power consumption;

- fuel consumption in normal mode;

- the diameter of the inlet and outlet with the recommended method of connecting pipes or hoses.

Motor-pumps, like any other technical devices, are selected on the principle of reasonable sufficiency. They should be designed for the conditions of your application and have characteristics slightly higher than the required parameters.

Industrial Motor Pumps can pump hundreds of cubic meters of water per hour with pressures of tens of atmospheres.It should be understood that more powerful equipment is expensive and requires high operating costs.

To give you need very small units, the task of which is reduced to the organization of watering or filling of some containers. In this case, consumption is rarely required in excess of 10 m.3/ hour or 180 l / min.

At head selection everything looks more complicated. Be sure to take into account the height difference between the installation location of the pump and the location of the points of analysis. Also affects the hydraulic resistance of the discharge pipe associated with its length, diameter and the presence of taps. Engineering calculations for the water supply of the garden plot, located next to a well or a natural reservoir, you can hardly produce, but provide 2-3 atmospheric pressure margin need to be sure.

Overview of popular manufacturers

High-quality pumping equipment is not cheap. If you want to use it as efficiently as possible, and not to search for spare parts and endless repairs, buy products only from trusted manufacturers. The best motor-pumps are traditionally made. in Europe, USA and Japan.

In the rating of motor-pumps the leading positions are occupied by such world brands as Honda, Hitachi, Subaru, Fubag, DDE, Hyuter. Prices for the most popular models with internal combustion engines for clean water start at 10,000 rubles, and for mud ones - at least 20,000 rubles. More budget Russian and Chinese brands Kraton, Caliber, Patriot, Champion and Elitech can be purchased for 6,000 and 18,000 rubles, respectively.

In the review of motor pumps you can include the most popular models with an estimated value of each of them.

-

- Petrol pump for dirty water Honda WB20X with a capacity of 575 l / min and a pressure of 28 meters for 26,000 rubles.

- ROBIN-SUBARU PTG310S petrol motor pump for polluted water with a capacity of 1000 l / min and a pressure of 23 meters for 39,000 rubles.

- Petrol pump for low-contaminated water FUBAG PTH 600 with a capacity of 600 l / min and a pressure of 23 meters for 31,000 rubles.

- Petrol pump for clean water CHAMPION GP26-II with a capacity of 130 l / min and a pressure of 30 meters for 6,000 rubles.

- Petrol pump for dirty water Honda WB20X with a capacity of 575 l / min and a pressure of 28 meters for 26,000 rubles.

Is it possible and necessary to do a do-it-yourself motor-pump

Important! Pumping equipment belongs to the category of sufficiently technological products that require factory manufacturing of parts and precise assembly. Making a motor-pump with your own hands in artisanal conditions from beginning to end can hardly be considered an accessible task.

Some craftsmen report that to pump water motor piston pumpsmade from pneumatic bicycle pumps or pieces of water pipes. There is no doubt that if it is possible to start a motor-pump of a similar design, then it will not last long, and the efficiency of the motor due to poor fit of the pump elements will be at an extremely low level.

Engaging in constant disassembly and assembly of components in an attempt to achieve an acceptable result is not the most rewarding task. Do I need to spend my time and energy on it? The cost of small water pumps domestic class It allows you to purchase a durable and productive unit for your farm.

/rating_on.png)

/rating_off.png)