How to choose a circulation pump for heating a private house

To increase the efficiency of autonomous heating systems in apartments, private and country houses, circulating pumps are used. These devices have low cost, economical, low noise and installed even in older heating systems based on natural circulation.

Content

Features of circulating pumps for heating

The main purpose of circulating pumps (pumps) installed in heating systems is to ensure the constant movement of the coolant through the pipeline without increasing the pressure in it. Heated water, moving along the contour with a certain speed, uniformly gives off heat to all elements of the system. Due to this, space heating occurs quickly and with lower gas consumption required for heating the heating medium.

If a heating system is installed, for example, for a private house that will work according to the principle forced circulationit is not possible to install a circulating pump. Also, these pumps can be installed in heating systems operating on the principle natural circulation. Installing a pump increases the efficiency of the heating circuit and contributes to gas savings.

Buy circulating pumps for heating should be after studying the full range of this type of product, which is widely represented on the Internet, because the devices can differ not only structurally (“dry” and “wet”), but also in power, installation method. In addition, some models of circulation units are equipped with mode switches that change the speed of rotation of the shaft of the device.

Important! Separate models of pumps with adjustable operating modes can be equipped with automatics.It responds to changes in air temperature in the room and turns on the required rotor speed to reduce or increase the speed of water circulation in the system.

Advantages and disadvantages of circulating pumps

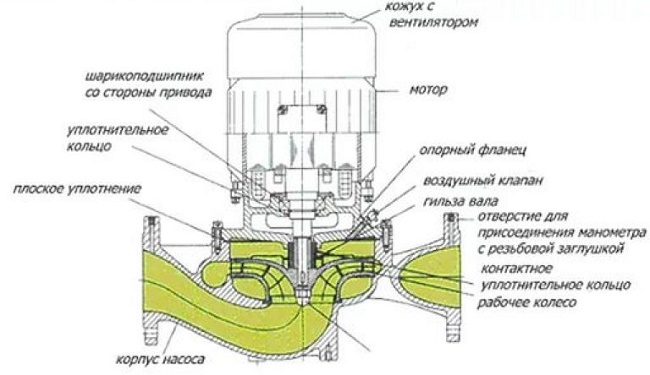

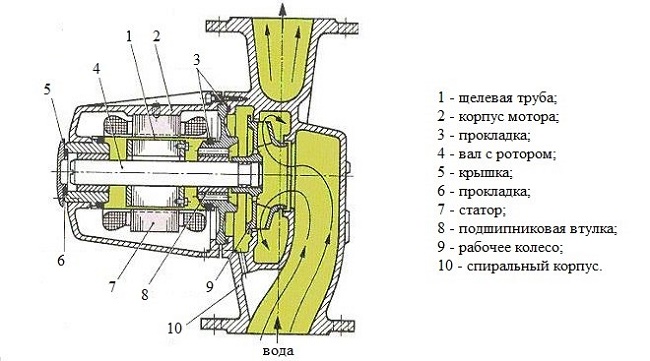

As mentioned above, circulation pumps have structural differences and are divided into devices with a “dry” and “wet” rotor. Both types of units work quite effectively and, due to their structural differences, have both advantages and disadvantages when used.

Dry Type Aggregates

Important! In the “dry” apparatuses, the rotor is not in contact with the coolant, and all elements of the engine are hermetically protected from ingress of the working fluid.

The advantages of the “dry” circulation pump include the following:

- high performance;

- maintainability;

- long service life;

- high efficiency (about 80%);

- can be installed in any position;

- reliability;

- low cost;

- the device can work without heat carrier in case of its leakage.

Cons of the unit with a “dry” rotor:

- high noise level is the main reason why this type of apparatus is not placed in residential premises;

- it is required to periodically carry out prophylaxis, consisting in the inspection of the apparatus and the lubrication of its moving elements.

Wet rotor machines

Important! In circulation pumps with a “wet” rotor, the latter is in contact with the coolant, which, besides its main function, performs the role of a cooler for engine components.

Advantages of “wet” circulation units:

- the minimum noise level allows to place the pump in residential areas;

- no lubrication of the moving parts of the device is required;

- simple installation and maintenance;

- the presence of a cooling method that does not require the installation of additional equipment;

- long service life;

- reasonable prices for devices and spare parts for them.

Disadvantages of “wet” circulation apparatus:

- low efficiency (about 30%);

- correct operation of the pump is possible only with the horizontal orientation of the rotor;

- unit cannot work without heat carrier.

Generally, Advantages of installing circulating pumps, regardless of their types, are as follows:

- indoor air, including those with large areas, warms up quickly;

- piping along with radiators heat up evenly;

- there is no air pipe;

- you can install towel warmers and thermostats;

- reduced gas consumption required to heat the coolant;

- Installation of the entire heating system can be done using small-diameter pipes.

Performance calculation

When choosing a circulating pump for heating, first of all, it is necessary to calculate its capacity, which means the volume pumped by the apparatus for a certain unit of time. Usually this unit characteristic is measured in l / min, l / h or m3/hour.

The performance of the circulation apparatus is calculated by the formula: Q = P / (1.163 x (Tf - Tr)).

- Q is the volume of coolant that pumps the pump in m3/hour.

- P - thermal consumption. It refers to heated rooms and is measured in watts (W). According to SNiP 2.04.07-86, for the heating system of a one-story or two-story house, taking into account the outdoor temperature ranging from -20 ° C to -30 ° C, the rate of heat consumption should be in the region of 173-177 W / m2. For high-rise, apartment buildings, this figure should be 97-101 W / m2.

- Tf - Tr is the temperature difference between the pipe coming out of the boiler and the return flow, through which water flows back to the boiler.If you intend to use a heating system with long pipelines, and even with water-heated floors, the temperature difference will be around 20 ° C. For short circuits with a small number of radiators, you can take a value of about 10 ° C. For a warm floor with a small area, the temperature difference will be around 5 ° C.

- 1.163 - coefficient indicating the specific heat of water, which, in most cases, the coolant. If antifreeze is applied, its heat capacity is determined by reference books.

On a note! Also, another formula is used to calculate the circulation apparatus capacity: Q = 3.6 x P / (С x (Tf - Tr)), where C stands for the heat capacity of water (equal to 4.2 kJ / kg * ° С). The meaning of the rest of the characters in the formula was described above.

For example, you want to calculate the performance of the circulation apparatus for a room of 100 m2. For calculations, the formula will be applied: Q = P / (1.163 x (Tf - Tr)).

We calculate the heat consumption by performing the selection on the area:

- P = 100 x 173 = 17300 W;

- further, we apply the formula: Q = 17300 / (1.163 x 20) = 743.7 kg / hour.

The resulting value can be converted to m3/hour.Since the density of water is 1000 kg / m3, then 743.7 / 1000 = 0.7437 m3/hour.

These calculations show that for the heating system, which is supposed to be installed in a room of 100 m2, you will need to purchase a circulation pump with a capacity of at least 0.75 m3/hour.

Head calculation

Head is one of the important characteristics, without which it is impossible to make the right choice of the pump for the heating circuit. This value is usually measured in meters of water column. In fact, the head is a parameter that indicates the height to which the pump is able to raise the coolant.

When calculating the head is very important take into account the loss of water pressure, because of its passage through all branches and turns, restrictions and extensions of the pipeline. This takes into account the number of different fittings and valves that occur in the path of the coolant, which also provide some resistance. Below is a table that shows the approximate values of pressure losses in the system, obtained experimentally.

Knowing the resistance index, the calculation of the head of the circulation pump is performed according to the formula: H = R x L x ZF / 10000.

- H - pressure circulation apparatus.

- R - pressure loss (see table above).

- L is the length of the entire heating circuit. That is, the total length of the supply and return pipes.

- ZF is the coefficient of additional resistance, which refers to various reinforcement and fittings. The value of this coefficient for valves and fittings is 1.3, for thermostatic valves - 1.7, and for mixers and devices that are designed to prevent natural circulation - 1.2.

- 10,000 - the conversion factor of the water column in Pa.

Additional functions (automatics)

As mentioned above, to ensure automatic switching on and off of the circulating apparatus, they are often used. electronic thermostats. Automation allows more efficient and effective use of the pump in the heating system.

The main task of the thermostat is to turn on the circulation apparatus, if the temperature in the system rises to the set level, and to turn off the unit when the coolant temperature decreases. On automation there is the possibility adjust hysteresis, that is, the difference between the temperature off and on in the range of 2-10 ° C.

Important! Some models of controllers have the “ANTISTOP” function, which does not allow the rotor of the apparatus to stall, for example, in the summer. There may also be an “ANTIMERING” function. Thanks to it, the forced circulation of the coolant in the system is activated, if its temperature reaches 5 ° C.

Installation of automation occurs in the hinged position, taking into account the length of the wires. The circulation pump is connected to the controller using an electrical cable. And the temperature sensor is fixed on the pipe. Clamping clamps can be used to fix the sensor.

Manufacturers Overview

Failure of the circulation pump, especially in winter, can lead to the exit of the entire heating system from the system, which will entail considerable financial investments for its restoration. Even if the breakdown of the pump is noticed on time, it is not always possible to quickly buy a new device, for example, if the house is far from the city.Therefore, it is recommended to immediately buy high-quality circulating equipment from reputable manufacturers.

Grundfos is a world-famous Danish manufacturer that has been manufacturing pumping equipment for more than 70 years. This manufacturer impresses with its fruitfulness, since it annually releases about a hundred new models of aggregates, which are successfully used both in the domestic sphere and in industry. The circulation pump models that Grundfos supplies to the market have the following features:

- cast iron, brass, stainless steel are used for the manufacture of pump casings;

- UPS models have 3 rotor speeds;

- Alpha2 units are equipped with automatics that regulate the rotor speed;

- powerful models of pumps capable of providing pressure up to 15 m and performance up to 15 m3/hour.

- Grundfos circulation units can be purchased at prices from 70 to 100 cu, the cost of powerful devices comes to 500 cu

Wilo - Manufacturer from Germany, supplying to the market a wide range of circulation pumps of various modifications, which are distinguished by stable operation and excellent quality. Wilo’s products have the following features:

- the devices comply with the EnEV energy saving directive, which implies automatic adjustment of the operation of the circulating equipment;

- pumps operate on alternating current with a voltage of 230/400 V (± 10%);

- the main material used for the manufacture of buildings is cast iron;

- devices can have power from 40 to 200 W;

- The price for Wilo units ranges from 50 to 100 USD

Dab - a famous manufacturer of circulating pumps from Italy. This company has been operating for more than 40 years and, together with other suppliers of pumping equipment, is competing in the domestic market, supplying A and AV series machines having the following characteristics:

- overload protection available;

- single phase models have 3 rotor speeds;

- devices can operate at a coolant temperature from -10 to + 110 ° C;

- household units of the AV series have a performance of 3.5 m3/ hour and pressure - 6.5 m, the devices of series A have a productivity of 16 m3/ hour and pressure - 11 m;

- choose a suitable model with a capacity of 3 m3/ hour and a pressure of 4.3 m can be priced at 60 cu

Important! In addition, DAB pumps have displays mounted on the control panel, making it easy to set up and monitor equipment.

/rating_off.png)