How to charge and store a screwdriver battery

Screwdriver - is one of the most popular in the home and professional power tools. It allows not only to twist and unscrew various types of fasteners, but also to drill holes. According to the method of powering the device are divided into mains and battery. Models with batteries are practically not inferior in their performance to tools operating from 220 V mains. At the same time, they can be used to perform work operations offline. It is also convenient that the power cord does not restrict movement. But you should properly charge and store the battery of the screwdriver so that it lasts a long time. Many problems with the battery pack can be solved by using the multimeter to identify the cause of the malfunction.

Content

Cordless screwdriver device

The battery is an energy source for cordless screwdrivers. Due to the course of physicochemical processes (electrolysis), this element accumulates electricity, and then delivers a constant voltage of the desired value at its respective outputs. Voltage and capacity are the main parameters of any drive. The first shows the potential difference between the cathode and the anode of the battery. Voltage is measured in volts. Capacity determines the amount of current delivered in 1 hour by the battery, therefore, this parameter is measured in ampere hours.

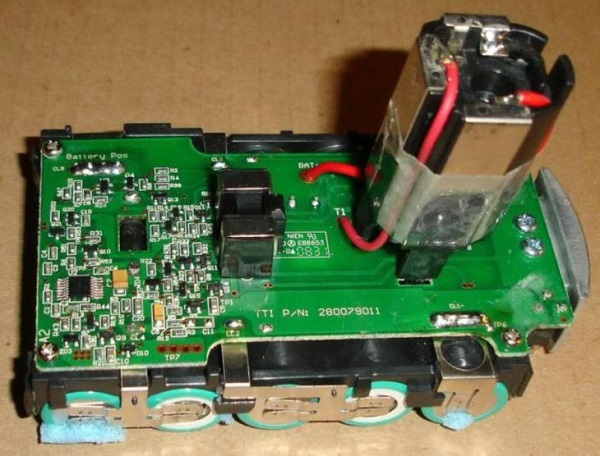

Different models of the battery pack (battery) looks and is arranged in a similar way. It consists of the following structural elements:

- enclosures with contacts located on it;

- power elements (batteries);

- a temperature sensor circuit (thermistor) that performs the function of protecting the unit from overheating (range from 50 to 600 degrees).

Not all models are equipped with thermistors.The case is usually a box of plastic, consisting of two parts. About 10 batteries are mainly placed inside it, and sometimes their number is larger. In this case, the batteries are connected to each other in a chain. The free terminals of the outer cans are connected to the contacts located on the housing, intended for powering the motor of the instrument and connecting it to the charging equipment. Battery output voltage determined by summing this parameter of all batteries connected in a single chain.

On the case of the battery there are 4 contacts:

- 2 power ("+", "-"), intended for charging and discharging;

- one control upper connected to the thermistor;

- one contact used for charging from special stations that are able to equalize the amount of charge for all batteries present in the unit.

By view of batteries Battery drives are divided into the following types:

- Nickel-metal hydride (designated - NiMh) with an output voltage of 1.2 V;

- Nickel-cadmium (marked NiCd) at the output also give 1.2 V;

- lithium-ion (denoted by the symbols Li-Ion), whose voltage depends on the number of power supply elements in the battery and can be in the range of 1.2-3.6 V.

Lithium-ion batteries have a control board.In this special controller monitors the operation of the batteries.

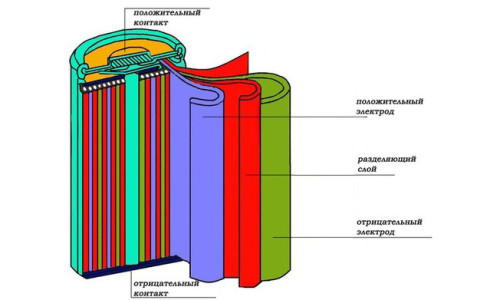

A separate battery consists of the following structural elements:

- positive and negative contacts;

- positive charge electrode;

- external covering of the case;

- electrolyte;

- negative electrode.

The most widespread are nickel-cadmium energy storage devices due to their affordable price, compact size and large capacity. They can be recharged more than 1 thousand times.

General rules for charging batteries

In order to properly charge the battery of the screwdriver, a certain external condition must be provided. temperature conditions. The optimum temperature is from 10 to 40 degrees. An undesirable point is the possible overheating of the battery pack during charge accumulation. To avoid possible negative consequences of this phenomenon, it is necessary to disconnect the battery for cooling from the charger.

It is not recommended after the batteries take up full capacity, leave them in the unplugged charger or insert them in a screwdriver that will not be used later, it is better to stack them in the case from under the tool.

Battery packs that are not used for a long period of time are recommended to be recharged once a month.

The recommended battery charging time is from 30 minutes to 7 hours and depends on its type. For a specific model of power tools it is indicated in the operating instructions. These instructions should be accurately followed in order for the product to last a long time. Most chargers equipped with indicatorsshowing what stage the process is at. In such cases, the lighting of the LEDs of a certain color is not difficult to determine how much you need to charge the batteries. After reaching the full level of capacity, you need to immediately stop the process.

Nuances of charging various types of batteries

Charging various types of battery packs has its own characteristics. They are associated with the properties of the materials from which the batteries are made. For regular charging of the battery packs, pulsed or conventional chargers are used. Adapters of the first type are equipped with a professional power tool, and the second - models for household use.New or discharged during storage must be properly charged before use, taking into account their characteristics.

So, nickel cadmium batteries characterized by a pronounced "memory effect". The first time it is recommended to charge them three times in a row, each time while completely discharging. Only in this way will be achieved the maximum (working) value of the battery capacity of the drive. After you need to conduct a regular connection of the screwdriver to the charger, when its power will fall to a minimum.

Have nickel metal hydride batteries there is also a “memory effect”. Before the first use, the full charge / discharge cycle for them is recommended to be repeated 4-5 times. During further operation, the charge is replenished as needed.

If the initial charging of batteries of nickel-cadmium and nickel-metal hydride types is not performed correctly, then the capacity of their batteries will gradually decrease.

Lithium Battery Packs the least whimsical. There are no special rules for them, because there is no “memory effect”.Lithium-ion power elements for a long time able to maintain their original performance level of working capacity. Each time it is not necessary to bring them to full charge / discharge.

Charging methods without using a special charger

When the standard charger is missing or just broken, you can do without it. The craftsmen have come up with different ways to replenish the battery charge from different sources. To charge the battery of a screwdriver without a standard sample charger, you can use:

- car charging;

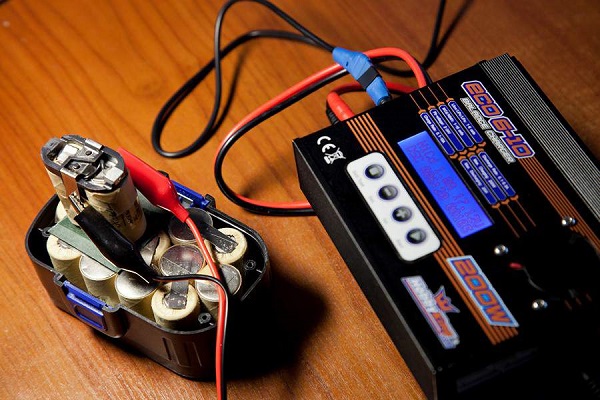

- universal charger;

- external sources of electricity.

The best option for car charging is a device with the ability to control the voltage and current. The main thing in such cases is to avoid overcharging. For this, the charging current is set to such limits that the process goes from 0.5 to 0.1 Ah, depending on the total capacitance. For example, if it is 1.3 A * h, then the current should be between 650 and 130 mA.

When the current values are too large, and smaller ones cannot be set by the regulator, additional resistance is applied, for example, a car lamp. It is connected in series to the battery pack.

Universal charging convenient to practice. They have a lot of additional settings that allow you to optimally choose the appropriate current parameters for charging batteries from different power tools.

External sources of electricity used mainly for worn-out screwdrivers, for which it is impractical from an economic point of view to acquire new batteries. In such cases, the power tool is upgraded in a certain way, with the development of an appropriate connection scheme. An example would be a reworked USB charging optionally equipped with a fuse.

Battery Storage Recommendations

It is recommended to store rechargeable batteries of any type by disconnecting from the screwdriver. Each type of battery also has its own characteristics in this regard:

- Nickel-cadmium batteries need to be discharged before storage to such an extent that the screwdriver does not work at all its capacity;

- Nickel-metal hydride batteries are recommended to be kept fully charged, but their small discharge is allowed;

- before storing a lithium-ion type battery, it also needs to be discharged,but only half.

After a long storage period nickel metal hydride batteriescapable of withstanding from 200 to 300 recharge cycles without loss of capacity, it is necessary to recharge within 24 hours. Blocks of this type are distinguished by a significant self-discharge parameter.

As mentioned above, lithium ion power elements devoid of "memory effect". They have high capacity and the lowest self-discharge rate. Replenish their charge at any time, despite the degree of discharge.

Li-Ion batteries should not be completely discharged, because this may cause the built-in electronic protection system to prevent temperature or voltage from turning off.

In order to achieve 50% of the charge required for proper storage, lithium-ion batteries need to be charged from a near-zero level over a period of about 65% of the time it takes to set up full capacity.

Compliance with the simplest recommendations for the storage and charging of different types of battery packs will allow you to work out the entire life of the batteries contained in them by manufacturers.

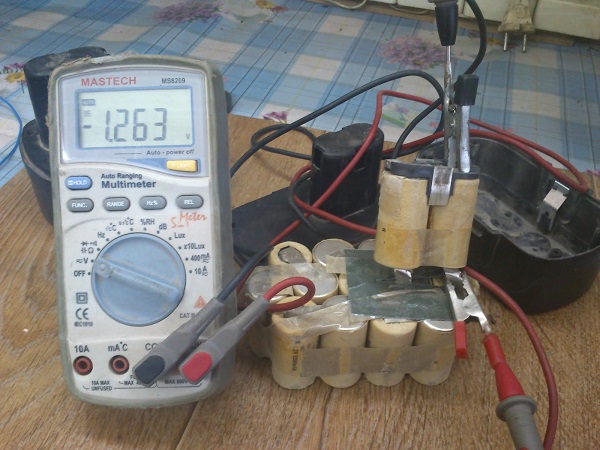

Checking the battery status with a multimeter

Not always, when the battery quickly sits down or does not function at all, it is necessary to buy a new one or carry the unit to a service center specialist. In many cases, even an inexperienced electrician will be able to find the cause of the malfunction, having become familiar with the search algorithm. To do this, you will need to use a multimeter or devices similar to it in terms of measurement capabilities. In addition to this device, the following tools are also required:

- screwdriver;

- soldering iron with a set for soldering;

- knife;

- pliers.

To accurately determine the cause of battery problems, you need to find out the performance of each individual power supply. But first recommended check charger. Using a multimeter do it this way:

- turn on the device;

- set the switch of the measured values of the multimeter to a constant voltage;

- install the probes in the corresponding sockets of the multimeter and touch them to the contacts ("+" and "-") of the charger;

- compare the value displayed on the instrument panel with the output voltage of the charging device indicated in the instruction manual or on the case;

- if the values do not match, then repair the adapter or buy a new one.

When it is possible, select the measurement range on the instrument used that is closest to the output voltage indicated on the charger.

To check screwdriver battery multimeter, perform the following actions:

- charge fully battery pack;

- check the output voltage of the battery with a multimeter by setting the instrument switch to its constant value, and touching the plus and minus with the probes;

- if there is a discrepancy between the measured parameter and the value indicated in the operating manual, then the battery pack is disassembled and all batteries are taken out;

- when there are no damaged banks (dripped or swollen), then they check the voltage on the terminals of each battery with a multimeter, first soldering the circuit with a soldering iron;

- to the batteries in turn, the load is connected for the same time (for example, a light bulb of the corresponding voltage);

- On which battery the greatest drawdown occurred, it is damaged.

For testing, nickel metal hydride and nickel cadmium energy storage devices are completely discharged - this is done in order to avoid the “memory effect”.

When testing the batteries, it should be noted that for nickel-cadmium and nickel-metal hydride types of batteries, the output voltage should be in the range from 1.2 to 1.4 V, and for lithium batteries - from 3.6 to 3.8 V.

Having found a defective battery, you can replace it with a new one, or try to temporarily restore it by adding distilled water or exposure to high voltage. Also a multimeter can measure current: if it grows and in the first hour exceeds 1 A, then the battery is considered efficient.

If the voltage at the battery output is absent, then there is a high probability that the integrity of the circuit inside the unit is violated. At the same time, they also disassemble the unit and look first visually, and then with the help of a multimeter, the place of the break.

When starting to operate a new cordless screwdriver, you should carefully study the instructions for use of this product, supplied by the manufacturer. It is necessary to consider the features of the type of batteries installed on a power tool in order to properly perform their charging, as well as to store them for a long time. Compliance with simple recommendations will extend the life of the battery to the full exhaustion of the resource.When there is no brand charger, then the following alternative methods of charging will temporarily help.

If the battery capacity drops, the operating time on a single charge decreases, you can repair them yourself. To do this, it is sufficient to set the output current or voltage with a multimeter and compare their compliance with the standard values of these parameters.

/rating_on.png)

/rating_half.png)