What are the types of grinders

Grinding machine (CMM) is a tool indispensable when performing various kinds of finishing works: when polishing and grinding metal, wood, concrete, stone and other surfaces. Therefore, it is not difficult to guess that the choice of the grinder is made taking into account the types of work to be performed in each particular case. Existing types of grinding machines allow leveling irregularities on various materials, eliminate height differences, and produce rough and finish grinding of surfaces. They differ not only in their design, but also in their working principle.

Content

- 1 Angle Grinder

- 2 Straight grinder

- 3 Belt sander

- 4 Vibration (flat) grinding machines

- 5 Eccentric (orbital) devices

- 6 Planetary Grinders

- 7 Brush Grinders

- 8 Mosaic grinders

- 9 Deltoid sanders

- 10 Drum instruments

- 11 Polishing Grinders

- 12 Multifunctional Grinders

- 13 Wall and ceiling sander

- 14 Ultrasonic Grinders

- 15 Mini Grinders

- 16 Stationary units

- 17 Roller grinding machines

- 18 Pipe Grinders

Angle Grinder

Grinder - angle grinder (Bulgarian). It is available in almost every master. Due to the variety of polishing, grinding and grinding nozzles that exist for this tool, they can produce the following types of work:

- alignment of differences on wooden surfaces, as well as their grinding and polishing;

- paint stripping on concrete, wooden and metal surfaces;

- cleaning of metal surfaces from rust;

- leveling concrete walls and floors.

For concrete floors and walls special nozzles are used - diamond cups.

Straight grinder

This grinder is different from the Bulgarian spindle location. If in the Bulgarian the spindle is mounted on an angular gearbox, then in a straight ball worm it is installed along the tool axis. Direct grinder is used for work in hard to reach places thanks to a long trunk with a snap.

Also in production often used straight air grinder for cleaning welds and deburring edges of metal blanks.

The face grinder can be either with a collet clamp, or with a three-jaw chuck, which allows you to clamp in it a snap-in with different diameters of the shank.

Belt sander

This is an electric grinder whose working tool is emery paper tapeglued in the form of a ring. The tape is worn on a pair of rotating rollers, one of which is leading, and moves along a flat hold-down table located at the bottom of the unit.

The belt grinder, as a rule, has a high speed of movement of the abrasive element and has high power. With this unit you can:

- easily and quickly remove a layer of wood in a few millimeters;

- Align glued wooden blanks to a height, for example, when manufacturing doors;

- trim the edge of the part or round the corners of the workpiece;

- remove old paint or lacquer coating, both on wooden and metal surfaces;

- clean the metal from rust.

It is necessary to take into account the fact that, after the treatment of wood or metal of the CMM tape, longitudinal small scratches remain on the surface. To eliminate them will have to use orbital or surface grinding (vibration) CM.

Vibration (flat) grinding machines

These devices occupy an intermediate place between tape and orbital BL for the cleanliness of surface treatment. Vibration grinding machine has its advantages over other types of similar devices.

- Low price tooling. The ability to use ordinary sheets of sandpaper.

- The large flat sole of the unit allows you to handle a decent square material.

- Due to the simplicity of the design, the device has a low cost.

- The configuration of the sole of the CMM allows you to handle internal corners.

In addition, the surface grinder provides good processing quality surfaces, but slightly inferior in this parameter of the orbital CMM.

Eccentric (orbital) devices

Orbital sander differs from other types of CMM in that it works like a regular vibro sander, only with circular movements of the sole.

Due to the rotation of the working platform, a certain layer of material is removed, and the vibration sands and cleans the surface to be treated. Depth of processing is regulated by the force of pressing the tool. Equipment is attached to the base of the unit with velcro.

The eccentric grinder can be both electric and pneumatic. The eccentric pneumatic grinder is mainly used in production and has its advantages over electric tools.

- Since this circular CMM does not have an electric drive, then its weight is much less.

- Due to the low weight of the instrument, it is used for leveling walls and ceilings.

- Due to the lack of an engine, the unit has a minimum number of parts that can fail.

- The grinder can be used in places with increased explosive hazards where the use of power tools is prohibited.

Eccentric grinders conquer the first place among all units designed for grinding materials, thanks to the highest quality surface treatment. Therefore, “orbitalki” mainly used for fine grinding and polishing.With their help, they treat plastic, metal surfaces, perform grinding and polishing works on wood, polish surfaces coated with varnish. They are also often used in car service for preparing car bodies for painting and for polishing a car after painting.

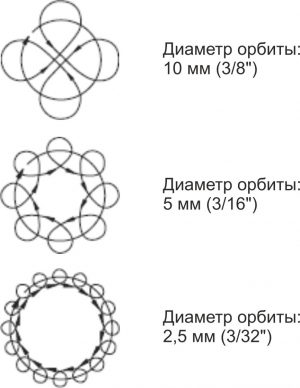

For standard polishing and grinding, “orbitals” are used with an eccentric stroke amplitude of 5 mm. For cars that require high quality polishing, it is better to choose a device with an amplitude of 3 mm.

Planetary Grinders

This type of grinders is used for polishing and grinding. stone surfacesFor example, in the manufacture of fireplaces, window sills, countertops and other products from this material. Planetary CMM consists of an electric drive and a grinding base of a planetary type.

Grinding tools are used on this device. diamond coated flexible discs. The unit is equipped with nozzles for supplying water cooling to the place of treatment and has a nozzle for connecting to a vacuum cleaner. The latter is connected to the CMM to remove stone dust during the “dry” grinding of the material.

Brush Grinders

The brush grinder is professional tool. With it, make polishing, cleaning and grinding of various materials. Using a special shaft mandrel, on the unit it is possible to establish various polishing and grinding nozzles.

In addition, a cylindrical brushing brush made of nylon can be mounted on the unit.

Brashirovalny nozzle allows you to structure the wood, that is, artificially give it the effect of aging, choosing a softer and friable layers of wood, leaving dense.

Thanks to this treatment, the surface of the wood becomes embossed and changes color.

Mosaic grinders

Mosaic grinder is used to process mosaic and concrete monolithic floors, as well as stone coatings. With this technique you can:

- to level various flows and to eliminate defects of floors;

- align the floors on the plane;

- to give the surface a certain degree of roughness before coating it with various decorative and protective compositions;

- polish large areas of concrete pavement.

As a tooling for concrete in mosaic grinders, special mills are used - frankfurt.Also, these cutters grind and floor mosaic.

Deltoid sanders

This is a separate class of vibration CMM, since their main difference is the deltoid sole. The people deltoid grinder received name "iron".

Some hand grinders of this type have rotary working platform. In such units, the ejected sanding angle can be changed by simply turning the bottom of the unit.

Due to its miniature size, the “iron” has a good “permeability” and is used to treat difficult surfaces, for example, for body repairs.

Drum instruments

For scraping the floor best suited drum grinder. It is a professional and versatile tool. Usually drum CMM is used for parquet (sanding and polishing before applying a lacquer coating) and for wooden flooring (removing old paint, leveling board height differences).

Drum machine works with any types of sandpaper. An emery tape is installed on the drum with a width of 20 cm and a length of 70 cm, which is fixed with special clips.

Polishing Grinders

Polishing grinders are mainly used for grinding (polishing) car bodies. In terms of its appearance, the polishing machine is very similar to a regular grinder, but differs from the grinder in the following ways.

- The handle is located on top of the case, that is parallel to the working tool.

- The unit has a low minimum spindle speed (800 rev / min), which is very important for polishing work. For comparison, at the Bulgarian this indicator can be in limits of 2800 rpm.

- There is a function of maintaining the speed on the same level, even under load.

- Polishers are always available with speed control and smooth start.

Polishing CMM can also be battery type.

You should know that the battery grinder is able to work effectively only for 20-30 minutes, after which it needs to be put on recharging.

Multifunctional Grinders

This type of aggregate is combined, since it can replace several tools: polishing, vibratory, deltoid grinding machine and cutter.

The multi-function grinder easily turns into a cutter for metal, wood and ceramics, if you replace the pad for grinding nozzles with special knives.

Wall and ceiling sander

The one-disk grinder has a comfortable long handle that allows to use the unit for walls and ceilings.

This grinder is used for puttying (its leveling), for sanding drywall, as well as for removing old paint or whitewash. The working tool can develop from 600 to 1500 rpm, and the unit itself has a power of 600 watts. Also, this disk grinder has a pipe with a diameter of 36 mm, which allows connect the vacuum cleaner hose to it. Because of this, all work on leveling the walls and ceilings occur with virtually no dust.

Ultrasonic Grinders

An ultrasonic grinder is the smallest and quietest setting that allows for delicately removing material from the surface of the workpiece, layer by layer. The unit consists of a source of ultrasound and a radiator with a ceramic file.

Ultrasonic micro grinding machine allows you to remove a layer of material with a thickness of a few hundredths of a millimeter. Also, due to the fact that polishing occurs without reciprocating movements, the probability of removing excess is minimized.

Mini Grinders

This type includes miniature drillswhich are also called engravers.

Due to the variety of nozzles, the mini-grinder can be used for grinding, carving, polishing, engraving and drilling, both wooden and metal products. Also, this unit has the ability flexible shaft connectionsthat allows you to handle the details of complex configuration.

Stationary units

For stationary units can be attributed to the belt-disc grinding machines.

Stationary CMM is mainly used in small carpentry workshops or in the conditions of small-scale production. The unit consists of a belt grinder and a grinding wheel. Thanks to the installed table on the machine, you can round the corners of the workpieces, grind the edge of the parts, and grind it at a certain angle.

Roller grinding machines

Roller grinder is designed for structuring, sanding wooden parts, as well as for matting and grinding metal surfaces.

The versatility of the tool is achieved through a wide range of equipment, which is easily changed without the use of additional tools.

Due to the special design of the “trunk”, this tool can be used to process parts in hard to reach places.

Pipe Grinders

The review is completed by a pipe sander, which has an original construction consisting of several rollers with an emery tape stretched on them.

Thanks to this design, it becomes possible to grind pipes in the 360 ° range in 2 stages. The unit is used for grinding welded joints, removing old paint, stripping pipes of rust and polishing them to a mirror finish.

Pipe grinders are of battery type, which allows them to be used away from the mains.

But, as mentioned above, the cordless tool does not differ long work. Therefore, you should prepare (charge) spare batteries in advance.

/rating_on.png)