How to work as an electric and laser engraver

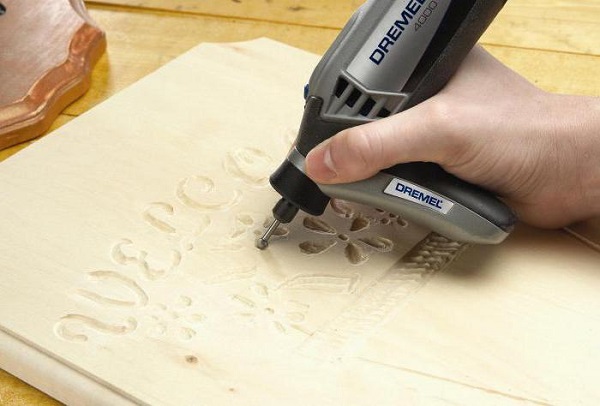

Work as an engraver is an interesting activity. With this device you can polish and grind small parts, cut various materials, display drawings, ornaments, patterns, inscriptions, drill holes and even create 3d elements on their surfaces. This multifunctional tool is also called Dremel, mini-drill, straight grinder, mini-milling machine, drill. At the same time one of the most common materials processed by an engraver, is a tree. To achieve an acceptable quality result, you need to know the specifics of setting up and operating the type of equipment used, as well as the scope of its possible use.

Content

Terms of wood engraver

In order to work productively as a wood engraver, you must first prepare the tool and the workplace. This will make the whole process more comfortable: there will be no need to be distracted by trifles. Only after these activities proceed to the immediate processing of wood.

The preparation work consists of the following operations.

- Workplace equip good lightingFor example, a powerful light bulb, so that you can easily handle the smallest details of the workpiece.

- All unnecessary items are removed from the workbench or table, covered with oilcloth or cardboard (to make it easier to collect chips).

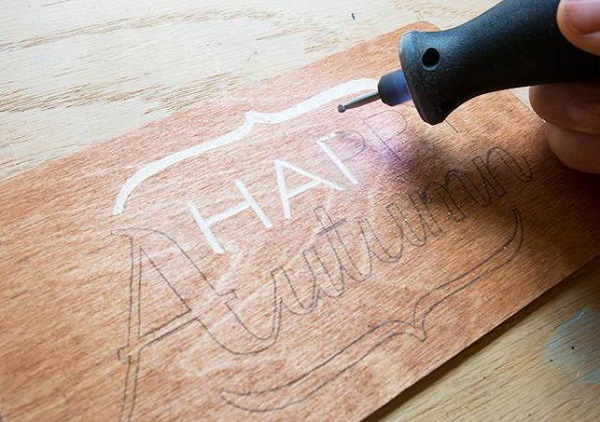

- Are cooking paper template (for example, a sketch of an inscription or a pattern) and an adhesive tape to fix it on the surface of the workpiece, or a pencil or a thin marker for drawing.

- Degrease with alcohol the working material.

- Lay out the nozzles designed to perform various works on the surface of the table in the sequence of their practical use in engraving.

- If a mini drill is used with flexible shaft, so that it does not interfere, the tool is hung on the rack.

Dremel with equipment is recommended to be stored in a separate case, when there is no properly equipped workshop. For each type of operation, certain nozzles are used: with the help of conical working parts, the outlines of the drawings are created, and using cylindrical parts, small details are made.

Wood engraving is performed in the following sequence:

- wear gloves made of cloth so that during work the hand slid easily;

- a prepared stencil is fixed on the surface of the wooden part or a sketch is drawn in pencil, and the entire area from which it is planned to remove the wood layer is hatched;

- they set the optimal speed for dremel to work with the processed type of wood;

- the contour of the ornament is denoted by the corresponding nozzle;

- remove the background from the surface of the workpiece;

- draw smaller elements;

- remove the remaining roughness.

If the experience in woodworking is small, then you can do all the operations at the minimum speed of the engraver - this will ensure accurate execution of all the manipulations.

Getting started engraving, you must comply with the requirements safety regulations:

- use only serviceable equipment;

- use safety glasses;

- when jamming the nozzle in the material must immediately turn off the mini-drill;

- periodically should rest (at this time the engraving machine will be cooled);

- apply the equipment corresponding to the number of working turns and the type of working operations performed.

For processing with a straight grinder, wooden workpieces from linden, alder, pear, beech. This is due to the monolithic structure of their wood.

Overview of laser and electric engravers

With the help of electric or laser dremels, it is possible to produce both the same and different work operations at home and in production - this determines the functionality of these tools. So, electric engraver performed:

- milling;

- cutting metal and other materials;

- engraving (2d and 3d);

- drilling;

- grinding;

- polishing;

- sharpening cutting edges;

- cleaning the surface of materials.

As for the list of operations performed, the laser tool is mainly needed for cutting materials and engraving, including 3D.You can also make holes with an engraver of this type.

You can work with laser and electric machines. with many materials:

- different in hardness metals (for example, gold, silver, platinum, steel, aluminum, copper) and their alloys;

- composites;

- plastic;

- rubber;

- ceramics;

- glass;

- wood;

- cardboard;

- natural (and artificial) stone;

- textolite;

- skin;

- bone;

- semiconductors and other.

The scope and list of materials with which certain models are capable of working is determined by their power.

With the help of the engraver do the following:

- various souvenirs;

- crafts;

- sheet plastic or metal is cut into pieces;

- create ornaments, patterns, drawings on the surface of various materials, display photos on them and transfer images;

- put marking on products;

- decorate the cup, medals;

- cut out plates, tags;

- decorate the furniture;

- perform the manufacture of mosaic tiles;

- process jewelry stones.

Engraving on metal is one of the most common works, rival wood processing. But the use of engraving equipment is not limited to this.Laser engravers are also used for cutting (cutting) fabrics, creating rubber stamps and seals, promotional products, logos. With their help, glass carving is easier. Without them, no cost manufacturing of printed circuit boards at the present level. With the help of machines with numerical software, 3D engraving can be done.

Non-contact mode of operation of laser devices allows no problems. engrave fragile materials. Also, this equipment does not round the corners, like electric dreamers, allowing you to make them of any sharpness.

In general, the performance of laser engravers is higher than that of electric models.

The work of a manual engraver requires practical skills and knowledge of the characteristics of the materials being processed. The quality of the achieved result largely depends on the skill of the engraver.

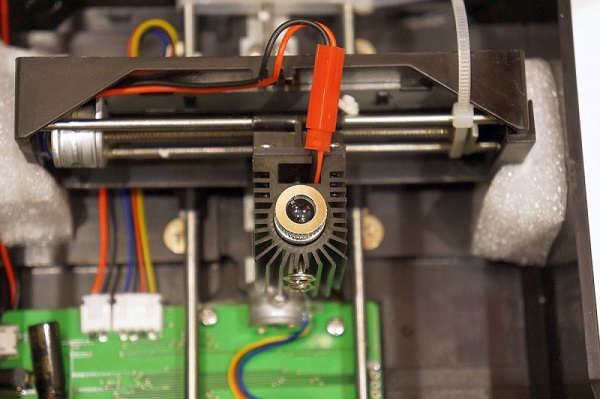

Setting up a laser engraver before work

The laser engraving machine must be set up before it can be started in order for it to function efficiently and correctly. First you need to do the preparation:

- install the machine on a flat hard surface, and then fix it;

- connect the ground to the equipment;

- check the presence of a cooler in the tank (water);

- connect the pump, compressor and machine to the mains.

You need to make sure at the end that no fluid leaks: if water runs out, the unit will quickly break.

Note that the height difference between the laser tube and the pump should not exceed 0.5 m.

Further adjustment of the laser engraver is performed in the following sequence:

- include pumping unit;

- check the circulation of water;

- supply power to the machine;

- include laser;

- connect the computer to the machine with a USB cable, run it;

- enter the software of the engraving machine, where they set the values of the current parameters;

- perform the adjustment (adjust the movement of the beam) laser engraver, performing the process control using certain keys that are available on the machine panel.

Can do based on arduino homemade laser engraving machines. They will be able to process corkwood, plastic and some other materials. If you connect a laser to Arduino, the engraver will also need to be customized.

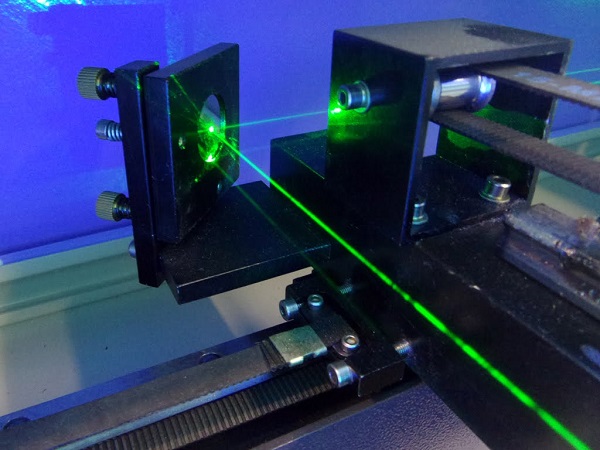

Carrying out the adjustment and determination of the focal length

The alignment of the laser engraver is carried out in this sequence.

- Include equipment.

- In the work area in front of each reflector is placed on a cardboard sheet of a suitable size.

- Press the button, which includes the optical system of the machine. A laser beam appears, which leaves a mark on the cardboard.

- If the label is not located in the center of the reflector, then the laser tube is centered using a special attachment.

- Press the start button again. In this case, the beam, having passed the first reflector, will create a spot on the cardboard.

- If the label does not coincide with the center of the other reflector, then adjust both reflectors: in one - the angle of reflection, and in the second - horizontal position.

- Similarly, adjust the remaining reflectors.

- Check the work of the machine.

Before adjustment, you need to check the laser power in the engraver, setting its value at a level not exceeding 80% of the maximum value of this parameter. You also need to protect your eyes with glasses and make sure that your hands do not fall into the beam field. In general, adjustment is recommended to perform together.

In addition to setting the movement of the beam, it is required set focal length. This parameter affects the accuracy and depth of engraving. All the work is done as follows:

- in the working area of the machine is placed, for example, plexiglass;

- unscrew the screw fixing the laser head;

- change the distance from it to the material, including the laser;

- leave the laser head in a position in which the spots were of the smallest diameter, but of the greatest depth.

The distance found will be the optimal focal length. After its determination and adjustment go directly to work on the machine.

Further maintenance of laser equipment

Caring for laser engraving machines of different sizes should be performed continuously. Timely proper maintenance allows you to extend the life of the equipment, ensures its continued effectiveness. For laser engraving installations it includes the following operations:

- checking the reliability of the grounding system for a machine with a computer;

- maintaining clean linear guides and lubrication;

- periodic replacement of the coolant (water);

- wiping mirrors and lenses from dust;

- fan cleaning and flutes.

Linear guides (X and Y axes) are wiped from dust with a dry cloth to a shine, having previously moved the laser head to the limit to the right or left position (forward or backward). Then they are lubricated using oil, for example, from sewing machines. To ensure that the lubricant is well distributed, move the laser head.

Water change produce about once every 2-5 days. For these purposes, it takes about 50 liters of purified water with a temperature of no more than 40 degrees (optimally + 5- + 25).

The frequency of fluid replacement and its volume depends on the model of laser engraver being operated. They are specified in the instructions for this machine equipment.

Inside the laser apparatus must be constantly dry. If moisture is detected, turn off the power and wipe off the liquid. Mirrors as well as lenses are very easily contaminated. This causes the equipment to stop working, damage its individual components. Cleaning is done with a cotton cloth moistened with acetone or alcohol. In this case, the lens should be handled with extreme caution so as not to miss it or damage the covering film.

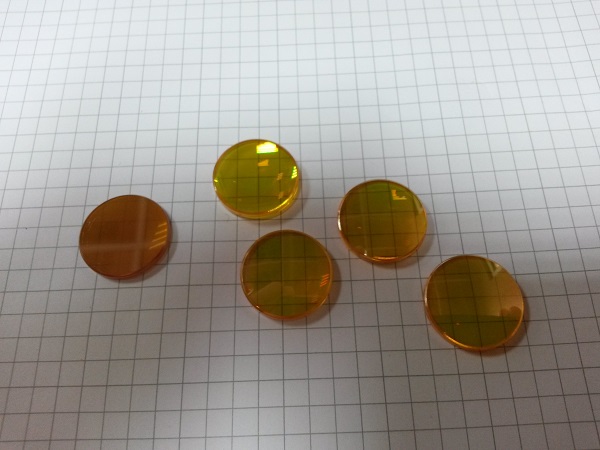

Laser Engraver Lenses

Over time, the internal hood with corrugations become clogged, with the result that more noise starts to emanate from the equipment during operation. These parts are first disconnected, and then wiped with a rag. If the engraving machine is equipped gas laser tube (CO2), then it will need to be replaced in about six months. The time interval depends on the intensity of operation.

It is necessary to keep clean not only the machine, but also the workplace itself. It is recommended to clean or check the dirty parts after every 8 hours of operation. The purity of optical elements affects the quality and depth of processing. Also for the engraving device is required to provide reliable power supply. For this purpose, it is recommended to use a voltage stabilizer, calculated on the appropriate power of the laser tool.

Rules for working with an electric engraver

To use the Dremel for a long time without repairs, it is necessary to properly organize its maintenance. Care is reduced to the following steps.

- Before the first practical use of the Dremel, it is recommended to turn it on for 20 seconds, while allowing it to work at the maximum and minimum idle speed.

- When working with electric tools, it is necessary to use only high-quality, unworn, nozzle products recommended by the manufacturer without any defects (cracks, bends).

- It is required every time after performing engraving or other manipulations with the device to clean the body of small particles of the material being processed, paying particular attention to air ventsdesigned for air cooling of an electric motor.

- While using the engraving device it is impossible to overload it, for which you need to do it regularly breaks in work (after about 20 minutes).

- It is forbidden to make any changes in the design of the apparatus and equipment.

- It is recommended to constantly check the integrity of the power cord as well as the adjustment of the power tool.

- Turning off the power of the device is necessary only with the power button, and not by pulling the plug out of the socket.

- It is necessary to constantly make sure that the operated tool was without visible damages, for example, cracks, dents, chips, as well as during operation there were no unusual sounds, overheating or vibrations.

- After every 50 hours of operation, the Dremel is worth inspect his brushes, to determine their condition and replace with heavy wear.

- Storage of a mini-drill should be carried out in a dusty, dry place.

Lubrication of the internal components of the power tool during maintenance is not carried out. It is applied in a thin layer only during long-term storage of equipment on the metal parts of the body and cartridge.

Nuances of care for power tools

It should be remembered that the manufacturer provides warranty service only when using those modifications of nozzles, which it indicates in the operating instructions for the equipment. If during the inspection it is found that the cutting edges of the working part become blunt, have cracks or other defects, then you should immediately replace it with a new one, because due to the use of such a nozzle, the load on the engraver increases, accelerating its wear. Deformed tooling in general can jam in the material being processed, which will lead to significant damage.

Dust from holes intended for blowing air with an electric motor should be cleaned with a humidified in a soapy water solution rags (or sponges) or blow off with air.To avoid possible damage to the outside of the plastic case of the power tool, it is forbidden to clean it with products containing solvent, ammonia, alcohol or gasoline. Working equipment also needs to be cleaned of sawdust and dust.

When detecting mechanical damage or atypical work (for example, the appearance of burning) of the operated engraving machine, it is necessary to immediately stop the ongoing operations. Then you should establish the cause and eliminate it. Ignoring often leads to complete failure of the product.

The engraver should be transported and stored in a case.

If an engraving machine is used with flexible shaft, it is also necessary to maintain this item:

- Before working, it is recommended to inspect the surface of the shaft for mechanical damage and then rub it with wax (paraffin) so that chips do not stick to it;

- after use, wipe with a cloth;

- periodically lubricate the tips with which the flexible shaft is connected to the nozzle and power tools;

- strong bending should not be allowed;

- after a time period set by the manufacturer, it is necessary to lubricate the flexible shaft of the engraver with the help of recommended oil.

The implementation of the considered simple recommendations will extend the life of the mini-drill for a long time. The quality of the performed engraving operations will be maintained at the original level.

All maintenance operations are carried out only with disconnected equipment.

Work with the engraver is associated with particular accuracy. Electric and laser engravers are used in many fields of activity in the home and at work, helping to solve various tasks. When using a hand-held power tool for wood processing, in order to obtain a qualitative result, the training and skills of such work are necessary. Laser engraving equipment must be pre-configured. But such machines work without workers: manages the whole process. special program, thanks to which getting a work of art has become easier.

/rating_off.png)