Overview of tips for engravers

An engraver, otherwise called a mini-drill, dremel, straight grinder or a drill, is a multifunctional tool. With it, they not only engrave, but also drill, grind and perform other operations on processing various materials, for example, wood, metal, glass, and stone. The device is widely used both in everyday life and in various industries, in jewelry, in the creation of advertising and souvenirs. All the variety of functional capabilities of the equipment due to the fact that there are different nozzles for the engraver.

Nozzles for frequently performed types of work are supplied with the tool. Cutters for more specific operations are required to be purchased separately. In order to work correctly and productively with a Dremel, while achieving high quality of machining of parts, it is necessary to know the existing types of tooling,and for what works apply each type.

Content

Nozzle classification

There are a large number of types of equipment for working with a mini-drill. A wide range on the market allows you to choose nozzles for wood and many other materials with which the engraving equipment can work. Also, individual masters make them on their own.

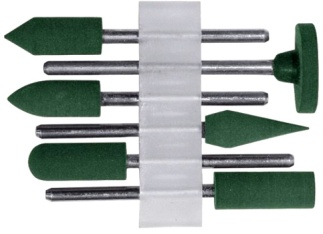

Structurally nozzles (burs) consist of two parts;

- tail, clamped in the tool holder (diameter from 0.8 to 8 mm);

- working, which processed materials.

The rigging is classified according to two main criteria:

- by the type of material from which they are made;

- by area of use (purpose).

By type of material being processed

According to the material of the cutter for the engraver are the following types.

- Hard alloys (carbide) with small and large working parts. Notching on them is of a different type.Intended for initial or intermediate processing of workpieces of different hardness.

- Steel with a diamond dustingused for basic work with various materials.

- Disk holders, which can be equipped with felt, cutting, rubber circles, depending on the properties of the workpiece and the nature of the work performed.

- Rubber with the addition of corundumused in the processing of metal blanks.

- Abrasivewhich are used to perform work on stone, metal, glass, ceramics.

- Feltdesigned for polishing wooden surfaces.

There are also combined burs, in which the shank is steel, and the working part is carbide. The area of their use corresponds to the material of the head.

Carbide tooling is high-quality, durable and belongs to a number of expensive consumables for Dremel. The shape of the tips determines the features of its application. With the help of such hog-peak it is good to process bone, plastic, to make a trace (to designate the contours of the figure). Diamond nozzles also differ in quality, even if the kit, which they include, belongs to the category of cheap consumables.

In the market you can find a set of burrs, all the elements of which marked with any color - it indicates the level of sharpening. Marked with black is the most productive burs, and the sharpness of green or blue is worse. Yellow marked nozzles are the best choice for finishing workpieces.

To destination

It is possible to use an engraver with nozzles not only for engraving, but also for other work operations. Separation of consumables used in the operation of straight grinders, presented in the table below.

| Work performed | Used nozzles |

| engraving | The above varieties are suitable. |

| drilling | performed using steel or carbide drills |

| polishing | circles of felt, cotton, felt, sandpaper, leather, as well as special devices (holders) that you can wrap yourself (for example, felt) |

| grinding | grinding stones (of various shapes and from different materials) and circles (from emery paper), diamond rings,rubber cylinders |

| groove | burs with a spherical working part |

| cutting | cutting discs |

| milling | cutters |

| surface cleaning (for example, from rust, scale) | wire (steel), cotton, fabric brushes |

| finishing holes or cavities | diamond cutters |

| slotting | conical burs |

Consumables from each group can be used in the processing of various materials. Wherein equipment for milling used mainly by professionals.

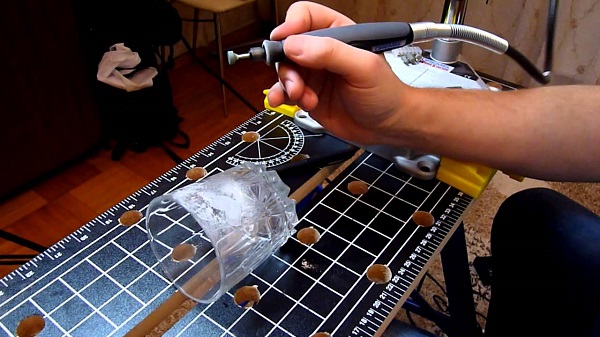

Dremeli, on which the flexible shaft is installed, are equipped with any kinds of consumables, suitable for the tool cartridge diameter.

Overview of the most popular tools for wood and metal

Wood is one of the most frequently processed when engraving materials along with glass, metal, stone. Dremels are often used in carving wood, drilling miniature holes in it, drawing images on the surface of a given material, grinding it, and also creating small grooves or dowels. Therefore, popular varieties of woodworking nozzles are:

- wood cutters;

- drill;

- cutting circles;

- polishing wheels, grinding wheels and cylinders;

- spherical and conical burs;

- diamond and carbide tips of different shapes;

- felt cones.

There are also specific types of cutters for wood, but they are used even by experts very rarely. It is recommended to purchase consumables in order to process different types of wood using a straight grinder. Thus, everything that may be needed when performing working manipulations will be collected immediately in one case.

Overview of professional tips for engravers

A professional tool is a separate (high-quality and expensive) category of equipment that is able to withstand significant operational loads without negative consequences. Such devices can be equipped with appropriate consumables.

Professionals process the smallest details of the blanks. Therefore, they need such a large variety of consumables when performing work.

Professionals involved in the engraving of various materials professionally, recommend to purchase sets of nozzles from famous brands, such as Dremel or Dexter. The significant cost of the products of these companies is fully justified by the fact that their products are distinguished by reliability, high quality and durability. The use of burrs for wood, metal and other materials produced by these companies increases the accuracy of processing of workpieces.

Often, specialists have several sets of equipment designed for processing different materials and performing various operations. Also, the individual elements included in their composition, have their own design features. Usually such sets include:

- cutters for metal, wood and other materials of different designs;

- drill;

- felt, diamond, and abrasive cones;

- wire brushes for cleaning surfaces;

- engraving rods;

- cutting discs.

Also included in the kit is a straight edge milling cutter.

Mill direct edging Topfix

Replaceable equipment of the Dremel and Dexter brands can be used not only by workshop specialists, but also by home craftsmen who wish to perfect themselves in the art of engraving.

According to professionals, one such tool can last as much time as 10 low-quality nozzles of unknown production.

Some engravers recommend products firms "Bison", less quality than the "Dremel" or "Dexter", but cheaper. The kit can include up to 180 units of consumables in demand. But products from Zubr, in general, belong to semi-professional and household categories.

Recommendations for the choice of nozzles

Usually milling attachment to the engraver is included in the set with the purchased tool. But with constant use, it eventually wears out. Also, cutters may be needed for specific operations - then you need to buy new burs to continue working with the Dremel.

The ideal option is to purchase products recommended by the engraver. In such cases, there is a guarantee from the firms on the operated device. But it happens that the original consumables are not available for any reason, or they will be very expensive with a small amount of upcoming work operations. Then you will need to purchase analogues or even apply homemade products. In this case, the main selection rules are as follows.

- Should be guided by a suitable chuck Dremel shank diameter: most often it is 2.4 or 3.2 mm.

- Need to purchase nozzles for metal and other materials under the type of work that is planned to perform.

- To engrave, you can use and inexpensive kitsFor example, Chinese or Russian production.

- With constant, long-term work with a mini-drill (especially with hard materials) it is recommended to acquire high-quality, professional kits, and in order to engrave occasionally, enough household ones.

During the training of various operations with the Dremel, inexpensive products will do. Over time, they should be abandoned in favor of better equipment.

Homemade tips on the engraver

You can buy tips on the engraver, not only factory-made, but also to do it yourself. Workshop specialists and home craftsmen have come up with many options that are suitable for performing various operations with different materials.

To make polishing, grinding, milling, drilling consumables for Dremel, as well as devices for cutting, use the following materials and parts:

- plywood;

- sandpaper;

- remnants of abrasive wheels of different thickness from the angle grinder (Bulgarian);

- felt;

- felt;

- various fabrics and rubber;

- steel wire;

- wheel from a cheap lighter;

- old burs and drills (they are resharpened);

- electric shaver knives;

- hacksaw blades;

- metal caps, for example, from beer bottles;

- champagne corks;

- the usual dowel (teeth are made on its bonnet) and others.

Below in the photos are presented some ready-to-use home-made devices for a milling type engraving device.

Additionally, with homemade apply special (eg diamond) pastes. At the same time, specialists achieve the result of finishing processing of workpieces of different density, comparable in quality using factory analogs of burs.

Homemade nozzles for the engraver fit to perform a variety of work in living conditions. They will also save money through the use of affordable, cheap materials and parts from improvised or out of order (unnecessary, old) mechanisms.

A wide variety of different nozzles allows you to perform with Dremel a wide range of differentworks with different materials. It is better to choose consumables that meet the recommendations of manufacturers of equipment. Professional Kits - This is a guarantee of product quality, but they are expensive. To save money, you can make the necessary fixtures yourself. Only it should be noted that in this case the warranty service on the mini-drill is lost, and during operation, the load on the tool may increase.

/rating_on.png)

/rating_off.png)