Faults and repair of the vibrating plate

The vibrating plate is a construction equipment which is used for consolidation of various bulk materials, for example, loose soil, sand, gravel and crushed stone mixture. It is used when laying paving slabs, building roads, compacting the soil on the building site, and for performing a number of other works. Equipment operating in relatively difficult conditions can fail at the most inopportune moment. This happens for a variety of reasons. However, many of the damage can be fixed on their own, without the help of a service center. In order to carry out repairs with your own hands, you need to understand the design of the working unit, as well as familiarize yourself with the most frequent breakdowns and their causes.

Content

Vibrating plate device

The design of vibrating plates of various types and sizes is almost the same. Different equipment models have the following main nodes:

- drive mechanism, which is the source of movement of equipment;

- eccentric (vibrator) - a node that creates vibrations;

- working (support) plate, which tamps the surface of the material;

- frame for the motor;

- Handle used to control the direction of movement.

By type of drive vibrating plates are divided into the following types:

- fuel (diesel and gasoline);

- electric.

The most widespread in practice are gasoline units, which are located at a cost between electric and diesel models.. They are equipped with four-stroke internal combustion engines (ICE) with one or two cylinders. Engine cooling is airborne. On many models, there is no gearbox.

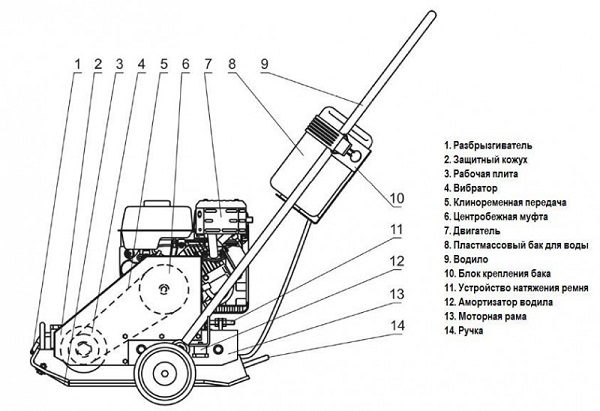

Detailed gasoline plate compactor device shown schematically in the photo below.

Vibrator consists of an unbalance shaft, which is installed in bearings with bearings. The motor frame is connected to the base plate through shock absorbers made of rubber and metal. With the help of a belt, the movement from the engine to the vibrator is transmitted, and the water tank is needed to wet the plate sole.

Support platform made of steel or cast iron. Various additives are added to the metal in order to reduce wear and thereby prolong its service life. Smaller parts, such as gears and cams, are made of plastic in cheap models, and in more expensive (high-quality) ones - from hardened steel. When working with paving stones or paving slabs, a mat made of polyurethane or rubber is additionally fitted to the working platform.

Also vibrating plates equip removable wheelsthat are needed to transport these units. Handles of units are often completed with vibration-proof linings in order to improve ease of operation and reduce the negative impact of fluctuations on the health of service personnel.

Equipment for compaction of bulk materials weighing from 0.7 tons in most cases does not have handles: it is managed remotely.

Electric models of vibrating plates are tied to the mains: electricity is supplied through the power cable with a plug at the end. The equipment is equipped with three-phase or single-phase electric motors. On the handle of the unit have a power button.

Electric vibrating plate SO-325

The main faults vibrating plates

All faults with vibrating plates are connected with their main nodes:

- driven;

- vibro node;

- working sole and motor frame

Since the engine is the main unit of technology, the greatest number of failures is associated with it. Each type of drive is characterized by its own problems, so they should be disassembled separately.

Faults associated with the frame, stove and handle are extremely rare. Usually these elements of construction serve without problems for several years.

When on the sole, the handle or the frame for the motor there are minor cracks, they are eliminated using a welding machine. If the base is worn heavily, it is completely replaced. It also often perform installation of new shock absorbers.

How to fix problems with a vibrator

The main cause of damage to the vibrator is the flow of the gland located on the shaft, and the oil flows out. If the vibration mechanism is operated without lubrication, then the gears are erased, which leads to the failure of the entire assembly. Often in such cases, repair is not limited to their replacement, because the associated parts are destroyed. The vibro node is disassembled and subjected to major repairs.

Other possible reasons for the fact that the oscillating unit does not work, and the ways to eliminate them are given in the table below.

| Cause of trouble | Remedy |

| Engine runs at low speed | It is necessary to increase the number of revolutions of the motor. |

| Loose (slack) drive belt | If the degree of wear allows, then give a stretch, otherwise simply replace the item |

| Torn belt | Put a new belt for vibrating plates |

| Engine malfunction | Repair drive unit |

In order to identify a problem with a vibrator in time, you should monitor the presence of oil leakage: if it occurs, you must immediately replace the glands.

Repair of electric motor

Before checking equipment equipped with an electric motor, you should first check power supply voltage:

- if the electric motor is single-phase, then it should be 220 V, +/- permissible by the instruction deviations from this parameter;

- when a three-phase motor is installed on the unit, a voltage of 380 V is necessary (plus or minus, but within the specified limits).

Check the magnitude of the voltage in the outlet with a multimeter, having previously determined with the help of the instructions for what value the equipment electric motor is designed for. Switch device set to the desired range. Probes are inserted into the corresponding sockets.

Multimeter and similar measuring devices are indispensable when checking electrical equipment. With their help, the presence of breaks in the circuit is established, as well as the standard indicators of the resistance of the motor windings.

The causes of problems with the electric motor are presented in the table below, which also contains recommendations for repairing problems.

| Problems | The reasons | Troubleshooting Tips |

| The electric motor will not start | Start button broken | Should replace it |

| Power cord break | You need to find the place of the break and connect the broken wires, you can also replace the cable | |

| The fork is broken | Need to put a new plug | |

| Winding or Burning Winding | Replace the motor | |

| Bad contact or open circuit | It is required to establish the place of breakage, and then tighten the connection or connect the wiring | |

| Electric motor is heated | Overload | It is necessary to make regular pauses in work. |

| Bad contact in Barno | It is necessary to check the connection, tighten the contacts | |

| Burnt winding | Motor Replacement | |

| The motor stops suddenly (jerky) | The presence of bad contact in the electrical circuit | It is required to determine the place of poor conductivity and then restore it (for example, tightening the bolt contacts) |

| The engine is running and the belt does not rotate. | Cut the shaft | It is necessary to replace the motor itself or only the rotor. |

| Turns the pulley on the shaft | It is necessary to remove the pulley from the engine from the plate, then check the seats, and then replace the part (or just fasten it well) or repair the shaft | |

| The motor does not stop the start button | Short circuit in the control circuit | Find a closed area and disconnect the wiring. |

| Broke button | Need to replace it |

In very rare cases occurs motor seizure. Often the reason for this is related to the bearings.Therefore, they should be periodically lubricated according to the operating instructions, and in case of heavy wear, they should be replaced with new ones of the appropriate type.

Repair of the petrol unit

When starting to repair a gasoline internal combustion engine, you must first ensure that there is enough fuel in the tank of the non-functioning unit, the ignition switch is in the on position and the air damper is positioned correctly. This must be done in order not to disassemble the equipment once again and not to waste time in vain.

The most common problems with ICE are caused by the following reasons:

- low oil or its poor quality, while the motor does not start at all or stops during operation;

- air filter pollution, which leads to unstable operation of the motor, loss of power or even the impossibility of starting it;

- malfunctioning candlesthat causes problems with the launch of a gasoline unit or leads to its unstable functioning;

- severe pollution of the exhaust system elements (or burning a silencer), which affects a number of equipment performance characteristics;

- piston wear or the lack of proper adjustment of the carburetor, which leads to unstable operation without load or a drop in power.

To resolve the problems listed in the last paragraph, it is better to contact the specialists of the service center.

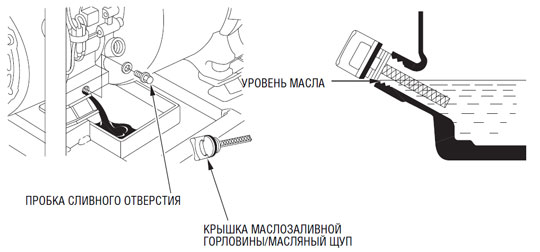

Oil check

If the oil level is below normal, the engine start in many modern models of seals is blocked built-in sensors. To test this, do this:

- install equipment on a flat platform (in the horizontal plane);

- unscrew the filler cap;

- insert the probe;

- determine the sufficiency of oil on it.

The oil for the vibrating plate is required to be periodically changed due to its pollution: the first time is after 20 hours, and all subsequent ones - every 100 hours of continuous operation of the equipment. Lubricant is better to use high quality. Oil should be stored in clean containers.

Cleaning the air filter

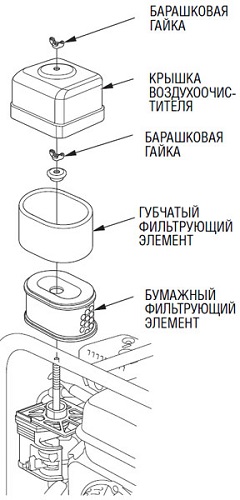

The air filter is cleaned as follows:

- remove, unscrewing the pre-nut, the air cleaner cover;

- unscrew the next nut and take out the filter elements;

- Wash the sponge filter with warm water with a conventional detergent,and then it is dried and moistened with motor oil, the excess of which is pressed;

- using compressed air to clean the filter element of paper;

- collect air filter.

The figure below shows air filter circuit and its elements.

Spark plug check

To check the condition of the spark plug (its pollution, wear, the distance between the electrodes) do the following:

- using the allen key, remove the candle;

- determine the degree of wear and the presence of defects, for example, chips;

- compare the size of the gap between the two electrodes with a nominal value of 0.7-0.8 mm, adjusting the distance if necessary;

- if the twisted candle can no longer be used, then put a new one.

Exhaust system maintenance

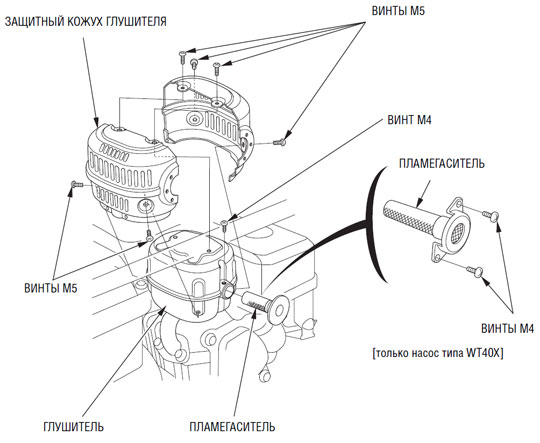

Device exhaust system shown in the diagram below.

Maintenance of the exhaust system is carried out as follows:

- unwinding the screws M5, remove the casing;

- to disconnect the silencer and flame arrester, unscrew the screw M4;

- using a metal brush, remove carbonaceous pollution;

- if the silencer is not burned, then collect the entire site.

If after checking the probable causes of breakdowns, the equipment works, but does not travel forward, then it is better to contact the service center.

To minimize the likelihood of damage to gasoline units to a minimum, you need to properly take care of equipment: time to change the oil, filters, candles. Before using the vibrating plate with any type of engine, it should be examined for external defects, it is also necessary to check the reliability of the bolted connections and the belt tension. After performing the work, it is required to clean the unit from various pollutants, for example, soot, dirt, oil. When operating the equipment, it is necessary to follow the recommendations set forth in the instructions for it. Simple rules will maximize the life of the equipment.

/rating_off.png)