Faults construction stapler and repair

Furniture stapler successfully replaced in many areas of the usual hammer and nails. Its use allows you to combine the same or different in hardness materials with each other, for example, wood, plywood, plastic, plastic wrap, fabric. With regular use, the tool can start to work poorly or even break at all, but many of the damage can be easily fixed with your own hands. To do this, you need to familiarize yourself with the design of the staple gun, its frequent malfunctions with ways to eliminate them, and also stock up on plumbing tools. Only in fairly rare cases, repairs will require the involvement of service center specialists.

Content

Stapler device

Staple guns according to the type of energy, with which the fasteners are driven into the material surface, are divided into the following types:

- mechanical;

- pneumatic;

- electric.

In everyday life, they mainly operate mechanical and electrical models of takers. The pneumatic tool belongs to the professional category.

Mechanical models

Any furniture stapler has in its design fastener shopInside which is a clip with guides. Insert the consumable material into it when performing working operations.

Shops of some models have a transparent insert. This is convenient during operation, because it allows you to control the remaining number of fasteners.

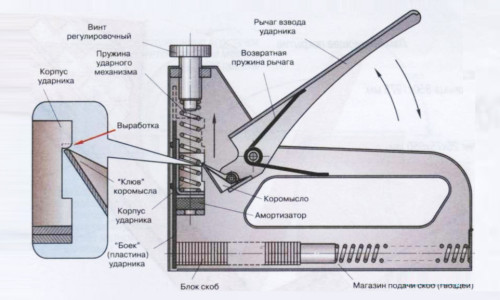

The device of a mechanical type scraper is shown in detail in the photo below.

Shock return mechanism (peen) is a plate.Its size corresponds to the geometrical parameters of consumables used. The striker is attached to the drummer - its shape is determined by the construction of the taker. In this case, the drummer with the other side is in contact with the spring, the compression of which is regulated by means of a screw. Shock damping is provided by a polyurethane shock absorber, which is located inside the case.

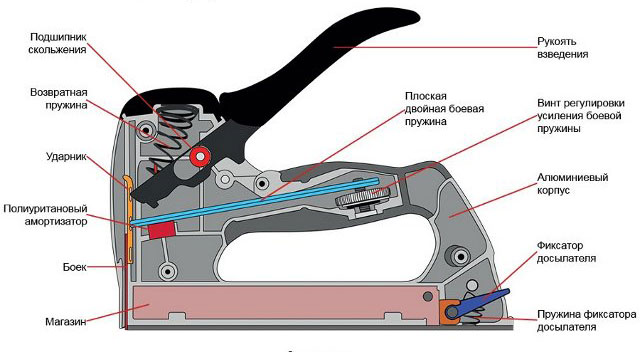

Hand staplers can be equipped springs of two varieties:

- twisted (shown in the photo above) installed on low-cost models;

- plate (spring type, picture below), more powerful and expensive compared to the first.

Mechanical Staple Gun controlled by lever (handle). He cocks the shock-return mechanism. During transport or storage, a safety clip protects against accidental operation.

Electric and pneumatic models

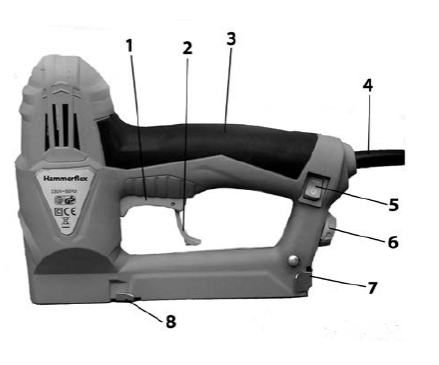

The device for an electrical tacker connected to the 220 V network is shown in the photo below.

The numbers denote the following structural elements:

- trigger trigger;

- fuse;

- handle to hold the tool;

- power cord;

- on / off button;

- mechanism for regulating the power of the shot;

- shop pusher;

- store lock.

Inside the instrument body are also:

- electric motor that cocks the spring;

- motor control board;

- impact mechanism.

Battery products do not have a power cord. The power tool is powered by batteries.

Separate design elements of pneumatic staple guns are shown in the photo below.

Inside the pneumotool is cylinder with piston, and also air distribution knot. Compressed air for the operation of the construction stapler enters through a hose capable of withstanding high pressure from a compressor unit or a cylinder. Therefore, if there are problems working with a pneumatic taker, you first need to check the serviceability of the compressor with the air duct.

Common malfunctions of a construction stapler and their causes

A construction stapler of any kind can start to work badly. In this case, common problems for the considered types of staple guns are the same. Only the reasons why the breakdown occurred can be very different - this is due to the constructive differences between different types of takers.Consider what to do in each case.

The tool does not work - do not fly staples

So, if an electric or mechanical staple gun does not shoot staples or nails, then the reasons may be as follows:

- the spring broke;

- problems with a drummer.

Mechanical devices may also wear the hook mechanism of the platoon lever with a spring.

Have power tools There are also such possible reasons why the fasteners are not fired:

- the tool is not included in the network 220 V;

- defective cord (its integrity is broken);

- electric motor burned out;

- control board of the electric motor is out of order.

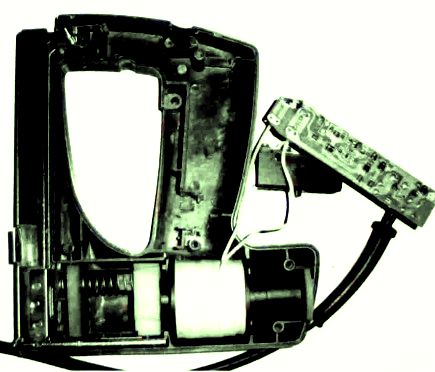

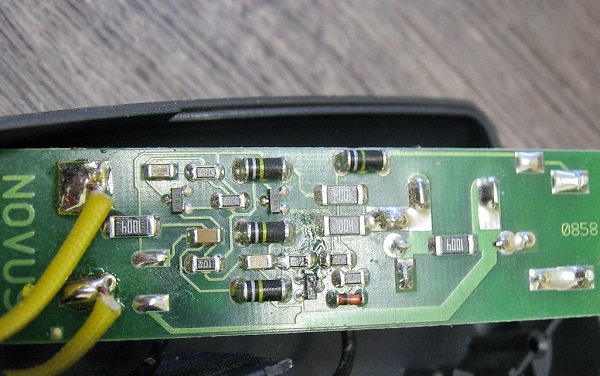

Payment of the electric stapler Novus J-165-EAD

Pneumatic tool Consumer does not shoot in such cases:

- the compressor is broken or not connected to the mains;

- broken hose;

- ended the compressed air in the cylinder;

- problems with the cylinder, piston or air distribution system.

Fastener gets stuck

Consumables in all models stuck for common reasons:

- when it does not fit in size for the operated taker;

- the fixture or shop from inside is polluted;

- used consumables with defects, for example, bent.

Staples are not completely hammered or, conversely, too deep

Any stapling gun does not completely fill staples, nails or pins, if depth adjuster set incorrectly. In such cases, it is enough to properly adjust it. For hand-held and electric devices, the problem is also often associated with spring wear, and for pneumatic ones, it is associated with a pressure mechanism or insufficient working pressure.

If the fastener is driven in too deeply, then the cause may be clamped spring or high pressure compressed air.

Important! The pressure of compressed air when using pneumatic tools can be increased no more than to the value specified in the instruction manual.

2 staples fly out during the shot

When a stapler knocks out two staples during a shot, the simplest cause of the problem is the use of dirty consumables or staples that are not appropriate in size. A pneumatic scraper problem may be due to a malfunction of the compressed air supply. In electrical and mechanical models, the problem is often also caused by wear on the striker or deformation of the striker (or its guides).

It also happens that the equipment is the yoke of the cramp.This is also due to their poor quality or the lack of conformity of the consumable in strength to the material of the elements being joined.

Stapler disassembly and troubleshooting algorithm

To repair the broken stapler for furniture of mechanical type, you will need the following tools:

- screwdrivers;

- vice;

- file or small metal file;

- hammer;

- pliers.

In some cases, you may also need a hand saw for metal or a grinder, while repairing power tools - a multimeter and a soldering iron with a set for soldering.

To check the freedom of movement of consumables inside the store, simply open it or pull out the pusher.

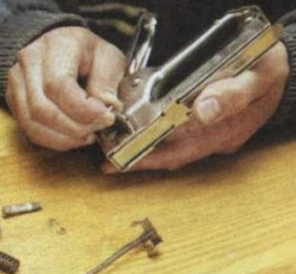

Spring replacement or repair worn shock mechanism perform in the following sequence:

- get the remaining consumables from the store;

- unscrew the screw that regulates the force of impact;

- take out the spring;

- disassemble the tool body, for this purpose, remove the washers and pull the pins;

- take out the impact mechanism;

- if the fault is related to the spring, then replace it;

- when the drummer is worn out (there is an excavation in the striker or in the place of contact with the starting lever arm), it is clamped in a vice and the parts are attached with a file or file of the original shape;

- assemble the instrument in reverse order, while lubricating the impact mechanism.

On the percussion mechanism, the spring support may also be broken (photo below), and because of this, the shooter does not work well. In this case, to fix the problem, you will need weld emphasisusing welding.

Repair activities do not take a lot of time and often do not require financial expenses, but they extend the service life of the staple gun.

How to disassemble and repair a pneumatic staple gun is shown in the video below.

Disassembly and preventive maintenance of the electric model of the staple is shown in the video below.

Tips for extending your life

In order to maximize the life, it is necessary to store the construction stapler under the following conditions:

- relative humidity of air not exceeding 70%;

- temperature should be above +5 degrees Celsius;

- The air of the storage place should not contain alkali vapors or acids, as well as dust abrasive inclusions.

In order to repair a stapler, in many cases you only need to properly adjust the depth of the shots, adjusting it for a certain material,and use quality, suitable for the size of fasteners. When the stapler does not work at all, more serious repairs will be required, often accompanied by the replacement of broken or worn assemblies. In carrying out repair operations, be sure to remember about personal safety: remove the consumables, put the device on a fuse and de-energize the electric and pneumatic models.

/rating_on.png)

/rating_off.png)