How to lubricate the punch

Lubrication punch is given an important place among the other procedures associated with the periodic maintenance of this tool. This preventive measure should be carried out after the time specified in the instructions for use. Timely replacement of grease reduces friction in the device, slows down the wear of parts, thereby prolonging its service life. It should be borne in mind that the old lubricant must be removed when making a new one. The punch grease is available from various manufacturers. At the same time for its individual nodes are its various types.

Content

What parts in the punch need to be lubricated?

In order to properly maintain the punch, you need to know what parts to lubricate in it, and with what frequency. This mechanism has a rather complicated device. It consists of the following main nodes:

- housing with vibration protection;

- electric motor having a vertical or horizontal arrangement;

- piston system;

- cartridge;

- gearbox, made in the form of a housing (housing), inside which are worm, bevel, cylindrical gears;

- safety clutch designed to stop rotation (when jamming the nozzle during operation) of the cartridge;

- working nozzle (drill, shovel, chisel, crowns or spikes).

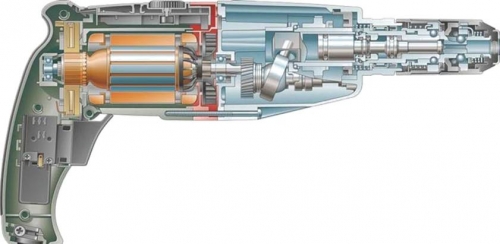

Schematic device punch presented in the photo below.

Gearbox - This is the node responsible for regulating the speed of the working nozzle. Its closed design is designed to protect the parts placed inside from dust, dirt and possible mechanical damage. While the tool is in operation, the gears are under significant loads, and the friction between them increases significantly.This leads to an increase in the rate of their wear.

As a rule, in various models of tools the gearbox goes blurry from the factory. But when the metal parts are destroyed. As a result, metallic dust is formed, which, mixing with the lubricant, leads to an increase in the friction force (hence, acceleration of wear). Slow down the process of destruction helps timely replacement of lubricating material.

It should also be borne in mind that often cheap models are smeared rather poorly with either material of dubious quality. They are recommended to lubricate again immediately after purchase.

In addition to the transmission mechanism, it should be treated with a lubricant. cartridge and seat plug-in interchangeable nozzle. The first one is shipped dry. Only the area in contact with the nozzle shank is coated in it: strong friction occurs at this place during tool operation. If it is not reduced, this leads to increased wear of the cartridge, up to and including severe damage. Also tail end it is quickly erased and can be deformed under the action of shock forces during strong heating, which is caused by friction.

How often to grease the instrument

Nozzle shanks should be lubricated with each installation, having previously wiped off dust or other contaminant. If the work is intensive, then you need to visually monitor the degree of lubrication of the seat used nozzles.

The puncher works for different users with different intensities: some use it every day, and others only occasionally. Therefore, there is no unequivocal answer about the regularity of making or replacing the lubricant. To decide on the need to replace the lubricant in the general case, you need to focus on the following:

- intensity of use of the tool;

- recommendations set forth on this issue in the instructions for punch;

- warranty period.

The most complete recommendations of manufacturers regarding lubrication of the tool assemblies are contained in the operating manual. Parts not indicated there do not need lubrication.

Features of the selection of lubricants for gearbox, drill, cartridge

Lubricant is a substance designed to reduce the friction force between parts interacting with each other.Of course, the friction partially remains, and during operation of the tool, the adjacent structural elements continue to wear out. But in the presence of lubrication, the process is significantly slower compared to dry friction.

Lubricants are synthetic, mineral and semi-synthetic. The second type is made from petroleum. It quickly loses its performance characteristics, it is often required to change.

The main parameter of lubricating products is the degree of its viscosity. Manufacturers of perforators in the instruction manual to them recommend using a lubricant with a certain value of this characteristic for the care of their instrument.

Each brand of lubricant has its own technical characteristics that should be considered when choosing. For lubrication gear gears, cartridge, shank nozzles use only types of compositions suitable for processing these parts.

So, the material used to reduce friction in the gearbox is not used to lubricate the drill.

To lubricate the punch gear, it is recommended to use gear oil. It is poured through a special hole in the body in the quantity required by the instructions. In doing so, it covers the interacting parts, filling the crankcase. Oil punch should be a liquid consistency.

SX75W90 GL4 1L gearbox oil

Also the gear mechanism is lubricated with special plastic compounds. But keep in mind that not all appliances are able to work normally when using substances with such consistency. If the gearbox parts (partially or completely) are plastic, it is possible to use silicone greaseFor example: 220-R Silicone DBC or HVS-100 Silicone # 3 from Huskey.

Silicone Grease 220-R Silicone DBC

To reduce friction between the tails of the nozzles and cartridges, you need to use thick formulationsindicating that they are intended directly for the Boers. If not, then you can use a graphite counterpart. But it removes heat worse than a special compound. Thick varieties of silicone greases are also used for cartridges.

Recommended lubricant manufacturers

The lubricant can be used as a brand (from manufacturers of perforators, for example, Hitachi, Metabo, AEG, Bosch, Bosch, Interskol, Bison), and from companies engaged in the release of lubricants (Xado, Ravenol, Shell and others).The most popular companies with a popular product range are presented in the table below.

| Manufacturing firm | Suitable range | Purpose of lubricant |

| Bosch | 3605430008, 1615430012 | perforator oils |

| 1615430005 | gear oil | |

| 1615430010, 1615430009 | for nozzle shanks | |

| 1615437512, 1615430014, 1615437511, 1615430015, 1615437509, 1615430019, 1615430016 | perforator greases in various packaging | |

| Makita | 181573-3 | for the Boers |

| 042024-0A | SDS + tool reducers | |

| 183477-5, 042005-4A | SDS + devices | |

| P-08361 | SDS MAX tool reducers | |

| Lubcon | Thermoplex ALN 250 EP | gear lubricant |

| Thermoplex ALN 1002 | for perforators | |

| Turmogrease NM 4602/0 | universal composition | |

| Nanotech | MetallPlak Electra | tailpiece processing |

| Metabo | 631800000 | grease augers |

| Bison | Bison Expert 60 | nozzle liner machining |

| Bison Expert 125 | ||

| Bison ZSB | ||

| Interskol | in 9000327 and in 9001698 | boraming |

| PRORAB | 0125 | plastic composition designed to handle the tails of the nozzles |

| Kress | 98035301 | boraming |

| different manufacturers | Litol-24, Litol-24 LUX | for gear lubrication and tooling |

Bosch and Makita gearbox oils are the most popular with consumers.

Bosch 3605430008 grease

When using a tool whose quality is confirmed by a special certificate, only lubricating products specified by the manufacturer of the device should be used. The use of other materials will lead to the loss of the possibility of warranty repair and maintenance of the punch.

Some may ask: is it appropriate? lithol for punching grease? It is connected with the fact that this lubricant is inferior in terms of its characteristics to specially developed formulations from reputable companies. Litol can be used, only need to change it more often. The best option for lubrication is the composition indicated by the manufacturer. When using it there will be no problems, incl. with warranty service.

How to properly lubricate the details: the algorithm of action

Lubrication the tail of the drill and chuck do it yourself is very simple. It is enough to perform such actions:

- wipe the cartridge and the tail part of the drill with contaminants from the contaminants present on their surface (old grease, dust);

- Apply a suitable composition to the nozzle shank or add directly to the nest.

You should constantly monitor the presence of lubricant, making it if necessary. Neglecting this recommendation will lead to overheating of the drill and increased chuck wear. In this case, the shank may flatten out or break away from the working part of the nozzle.

If the tool is equipped with an open cartridge, it should, after disassembling and cleaning it, lubricate the seals.

Regarding gear lubricationthings are a little more complicated. Most modern models are equipped with containers. In them, opening the cap, pour in the oil or make another suitable lubricant composition. The location of the desired hole is often indicated in the instructions. It also contains a scheme for removing the cover. The whole process goes like this:

- remove the lid;

- remove the remnants of the old lubricant composition;

- rinsed (for example, using a compressor) or washed crankcase gasoline;

- pour new oil in the amount regulated by the operating instruction so that its level does not exceed the existing reference mark;

- put the lid in place, closing the hole.

If the tool is under warranty, then only recommended oil should be poured. When there is no special hole to fill it, you will need disassemble the punch. If the warranty service is valid, it is recommended to contact the service center specialists about this.

Gear lubrication sequence with punch disassembly

If the warranty on the punch has expired, then you can do all the work on lubricating the gearbox yourself. You will need the following tools and materials:

- fitting set (screwdrivers with different nozzles, hex keys, pliers, etc.);

- clean rags;

- petrol;

- Lubricant type suitable according to the instructions.

Lubricate the punch reducer by performing the necessary actions according to the following algorithm:

- study the instruction manual for the device model used;

- clean the case from dust, and also from other available pollution;

- then proceed to disassemble the cartridge: using a screwdriver, remove the rubber and retaining rings (as shown in the photos below);

Rubber ring

Retaining ring

-

- remove the casing of the cartridge;

- remove the pressure ring;

- take out a spring, and also balls;

- remove the mode switch (for different models it is done in different ways);

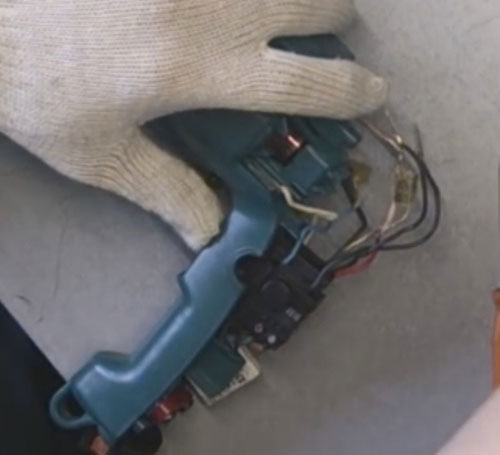

- unscrewing the screws using a screwdriver or a hex head, disassemble the rear part of the housing to detach the brushes from the collector;

- disassemble the front of the case: unscrew the screws, tightening it longitudinally;

- taken together with the motor shaft gear;

- wash out the removed parts and the device case from the inside from the old grease using a rag soaked in gasoline;

- wipe them with a dry cloth and allowed to dry;

- lubricate the gearbox completely, as shown in the photos below;

Lubricated Transmission Components

Fully Coated Gearbox

- collect punch.

Preliminary study of the instructions is necessary not only to learn how to properly use the tool, but also to get acquainted with the scheme of its disassembly and assembly.

Additional recommendations

When performing independent lubrication of the transmission node, it is necessary to take into account such recommendations.

- It is necessary to remember the exact location of the parts and fasteners to be removed, in order to install everything when assembling into place and not to leave extra spare parts.

- To disassemble the tool, in order to lubricate the gearbox, it should only be done when it is completely cool after work.

- On the non-lubricated structural elements to apply the composition is not required.

- The best option is to use branded lubricant formulations intended directly for the type of equipment used.

- Disassembled gearbox is desirable to inspect gear defects (their wear, lack of teeth, the presence of cracks) and other elements - this will help replace parts in time and avoid major problems in the future.

Photographing the entire disassembly process perforator will help to assemble it correctly.

Modern perforators are fairly easy to maintain. Lubrication of their working units does not take much time. The main thing is to use the composition recommended by the instruction or suitable for its purpose (or universal). During the complete disassembly of the equipment, it is necessary to work as carefully and carefully as possible to get a quality result. It is also necessary to observe safety precautions, greasing the tool disconnected from a power line.

/rating_off.png)