How the punch works and works

In the set of home wizard you can almost always find a punch. Replaceable nozzles make this tool versatile and indispensable. Let us take a closer look at which nodes it consists of, and how to work correctly for them.

Content

What is the punch

On the body of the instrument are the controls, as can be seen in the following photo:

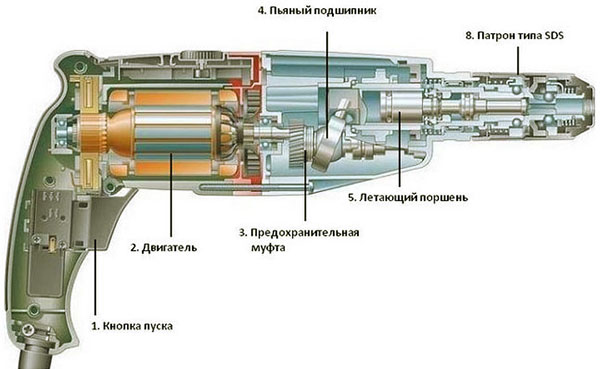

The internal structure of the punch cannot be understood without disassembling it. The following main components are hidden in the plastic case:

- electric motor;

- safety clutch;

- "Drunk" bearing;

- flying piston;

- cartridge.

The principle of operation of the perforator is to turn the rotation of the electric motor into a shock-rotational movement of the nozzles.. The motor drives the rest of the punch mechanism.Safety coupling ensures the safety of specialists during operation. Drunk bearing actuates the piston, creating a shock force, and the cartridge provides a clamping nozzles. Now let's talk more about each of these nodes.

Electric motor

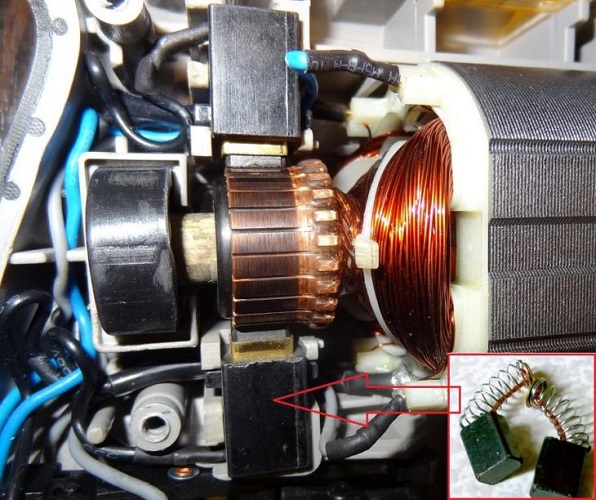

The main parts of the motor - stator and rotor.

The stator windings create a constant electromagnetic field within which the rotor rotates. On the rotor there are several windings. The terminals of the coils are connected to the terminals of the armature. At the same time, one of the windings is turned on in the electrical circuit. Power is supplied through graphite brushes to the armature contacts. By switching the windings, a slip field is created, due to which the rotor rotates.

The motor in the tool may have horizontal and vertical layout. Horizontal is commonly used in light perforators, while medium and high power models are equipped with a vertical electric motor.

In the latter case, a gearbox is added to the perforator design, changing the direction of rotation, increasing the torque and impact force of the tool.

The operation of the electrical part of the perforator is regulated by a trigger by pressing a key on the handle.

Safety clutch

To stop the rotation of the cartridge, if the working nozzle is jammed, a safety clutch is installed in the perforators. This is a necessary element: without using it, the powerful tool is twisted out of hand, the continuation of the independent rotation of the perforator easily leads to injuries to the worker. In perforators use two basic types of coupling devices: friction or cam.

- Under normal operating conditions of the tool drives friction clutch tightly pressed together - this is how the force of rotation is transmitted to the rest of the mechanism. If rotation is difficult, the discs slip without overloading the electric drive.

- AT cam clutch both its halves have sloping protrusions that are included in the grooves of the counterpart. The coupling halves are connected by a spring of a certain stiffness. If the force on the impact mechanism exceeds the spring pressure, the protrusions exit the slots, disengaging the clutch. During this, a characteristic rattle is heard, for which the cam clutch is often called a ratchet.

Impact mechanism

The percussion mechanism in the design of perforators is found in two types:

- electromechanical;

- electropneumatic.

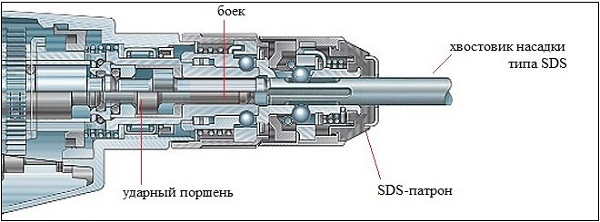

The most widespread electropneumatic option. "Drunk" (swinging) bearing and piston together constitute the percussion percussion mechanism.

When the main shaft rotates, the swing bearing performs translational movements, transferring the force to the ram of the pneumatic cylinder. The air in the cylinder pushes the piston briskly. The working part of the cartridge is subjected to strikes of the striker, the drill is clamped into the cartridge and hits the material being processed.

Cartridge

The cartridge for the perforator is designed in such a way that the user has the opportunity to quickly change the nozzle without making long breaks in the work. We are talking about cartridges of two main types:

- SDS-plus;

- SDS-max.

Tool shank for SDS-plus cartridge it is clamped by two lock balls.

AT cartridges SDS-max clamp tools with other shanks, providing a more secure fit.

What tool can do

There are the following main modes of operation of the punch:

- blow with rotation - allows you to drill a concrete wall;

- blow without rotation - to hammer concrete;

- rotation without impact - with a nozzle under the drill allows you to drill like a drill.

Those who often work with a perforator, know that in addition to drilling and chiselling of walls, such a tool can be used to make walls for wiring. Making a tile in concrete with this tool is quite simple. First, a series of holes are drilled along the marked lines. Then the jumpers between the holes are broken with a lance or a spatula. Such use of a punch is not typical, but it allows you to refuse to purchase additional tools.

Strobing perforator allows you to get not such an ideal result, as after a wall chaser, but the subsequent plaster hides all defects.

Operational safety

The perforator is an electromechanical tool, so you need to use them, observing safety measures.

- Before you begin, you need to make sure electrical cord integrity. A damaged plug or cord insulation may cause electric shock. Cracks in the casing can also be a source of danger.

- Replaceable nozzles must be securely fastened, otherwise during operation they may jump out of the cartridge and cause injury.

- You need to drill material without touching the rotating part of the tool: sharp edges easily damage hands and other parts of the body.

- Nozzles during rotation get very hot, therefore, after work is finished, it is not possible to touch them with bare hands in order to avoid burns.

To work properly with a power tool is to keep you healthy. Be sure to follow the rules of safety and wear personal protective equipment: gloves, mask or goggles, special work clothes.

/rating_off.png)