The choice of electroplane for home and professional activities

The electric planer is the most affordable woodworking tool, greatly increasing the efficiency of work at home, in construction and in small workshops. With it, sawn timber planed, chamfered from them, a quarter is chosen from the blanks. The use of this tool allows you to save on materials: acquire unplaned bars or boards, and then process them yourself until the desired surface quality is achieved.

On how well the electric planer will be selected for performance, will depend on the performance of working with him and the quality of processing of lumber. When choosing a model, it is also necessary to take into account the intended intensity of use.

Content

Electroplane selection options

The market is saturated with many models from manufacturers in different countries. In such circumstances, the choice of electroplane should be carried out consciously. The following instrument features should be considered:

- price;

- specifications;

- ergonomics;

- additional functionality.

These criteria are combined in technical products in different ways. The task of the user is to choose the optimal version of the product. The cost of electric planers varies in a wide range: from a few thousand for household tools to hundreds of thousands for professional products intended for intensive practical use.

The appearance of the power tool does not act as a serious criterion. Each person has their own preferences regarding the color and geometry of devices. But if the form of the tool has an impact on the usability of working with it, then it must be taken into account before you buy the product you like externally.Famous brands use individual colors to paint products, for example:

- Makita - blue;

- DeWalt is yellow;

- Bosch - blue and green;

- Hilti is red.

In addition to brand affiliation, at Bosch, green indicates that the electric planer is intended for cottage or at home, and blue indicates the professional purpose of the instrument.

Knowing the colors used by popular manufacturers is one of the signs you can use to distinguish fake products from the original.

Technical indicators

Complete with electric planers must go documentation. It contains all the data on the technical characteristics of the instrument model of interest. Also availability of equipment passport indirectly indicates the solidity of the company producing products. The most important technical characteristics for a correct choice of the electric tool with a range of their possible or recommended values are presented in the table below.

| Performance indicator | Value range |

| motor power value | from 400 W to 2 kW |

| RPM | 10000÷19000 |

| planing width | 50, 75, 82, 102 and 110 mm are the standard of knives (their number is from 1 to 3), for professional models it can be 170 and even 312 mm |

| product weight | 2.5 ÷ 9 kg |

| cutting layer depth when planing | 0.1 ÷ 18 mm |

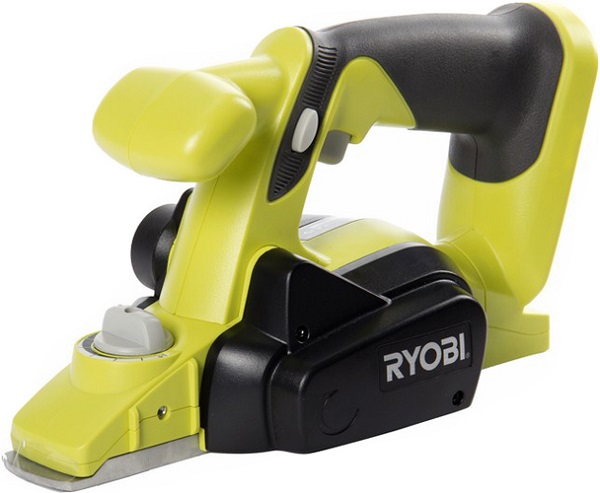

In battery models, an important parameter is the capacity of the battery and the output voltage (18 or 14.5 V). A wireless tool is convenient to use if there is no access to the 220 V mains supply, and it is also safer from the point of view of the possibility of electric shock.

Accumulator electroplane RYOBI CPL 180 MHG

It is on the considered technical characteristics of the electric planer depend on its basic functionality, as well as the convenience of working with this tool. The greater the power of the tool used, the faster the lumber can be processed with it. The quality of planing of sawn timber is determined by the speed with which the drum with knives rotates. Optimal speed determined by the properties of the treated wood:

- 10 thousand revolutions per minute are the right speed for planing softwood;

- more than 12,000 rpm is the required speed of rotation of the drum when machining hardwood blanks.

Taking into account these factors, it is recommended to purchase a universal electric planer for domestic needs with the ability to control the drum speed in the range of 10,000 ÷ 15,000 rpm, which has a capacity of up to 1 kW.

It is necessary to take into account how the speed of rotation of knives changes under load compared to idling: for good quality models, this parameter remains stable.

Between and power and depth planing direct dependence, which is presented in the table below.

| Power of the electric tool, W | Thickness of the layer which is cut off for pass, mm |

| up to 500 | up to 1 |

| 600÷800 | until 3 |

| more than 800 | over 4,5 |

Also, the more powerful the equipment, the wider the drums can be installed on it. Optimal knife width It is considered 82 mm. They are easy to find for sale when replacing. Blades can be:

- carbide (high carbon alloys);

- from high-speed steel.

The first ones are more durable and expensive, and the second ones are less solid, but are cheap and can be sharpened. HSS knives are most common.

If you want to process the surface of the workpiece with the highest quality, it is recommended to use the spiral double-sided knives.

Ergonomics

Under the ergonomics of an electric planer understand the convenience of its practical use. This criterion is mainly focused on well-known manufacturers. Recommendations for incorporating the ergonomic characteristics of selectable devices are as follows.

- Better to work when the power tool is not equipped with one, but two handleslocated at a convenient angle (for each its value is different, therefore, should be selected by comparison). The best option - when there is a handle rubber liningthat perform anti-slip function.

- Well, if you can blow off the chips when planing and collect it in a bag.

- Must be planing depth scale with a graduation price of 0.1 mm.

- The optimum weight of the tool is 3-3.5 kg so that hands do not get tired during the processing of lumber.

- The greater the area of the sole, the more stable the electroplane during operation. The sole after exposure should create a single plane without distortions.

- The electrical planer body must be made of high-quality plasticscharacterized by gloss and lack of fragile, thin structural elements.

- For practical use, it is convenient when the drive belt is equipped with a cover that can be easily removed, which allows for quick replacement if necessary.

The chosen working tool must be well balanced, with a convenient location of the start button (so that it can be turned on with one finger). If you need the help of the other hand to turn on the device, then it is not recommended to purchase such models. When a manual electric planer weighs more than 4 kg, fatigue comes faster, which can adversely affect productivity.

In terms of ergonomics, there are no exact criteria: each user has his own individual preferences and physical features. But if the working tool is equipped with two handles, this allows you to evenly distribute the effort and load during the processing of lumber, and also increases the degree of safety of the labor process.

Additional features of electric planers

To choose the best tool, you should also take into account the available additional opportunities. They provide:

- availability of a smooth start system that reduces wear on parts, extending the period of their work without repair;

- equipment with an electrodynamic brake, which reduces the time of stopping the drum from 4-5 s to 2-3;

- control system and stabilization of the speed of rotation of the working drum, which will prevent the motor from overheating under load;

- the presence of the second pipe;

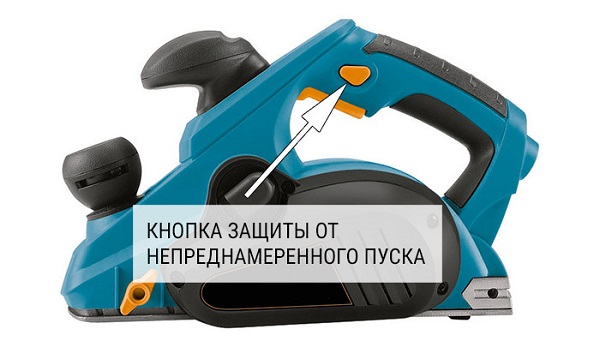

- possibility of blocking from involuntary switching on, preventing accidental switching on of the device;

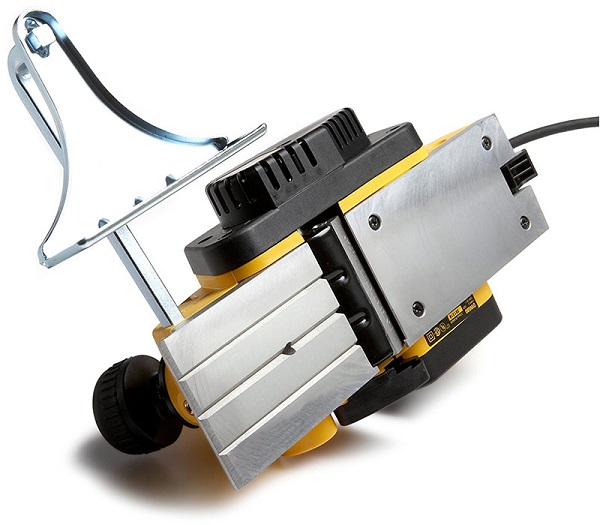

- the equipment is equipped with a fixer allowing fixing the tool on a workbench or table;

Electroplane RE-780/82 with a metal stand for stationary use

- ruler, side stop, corner stop.

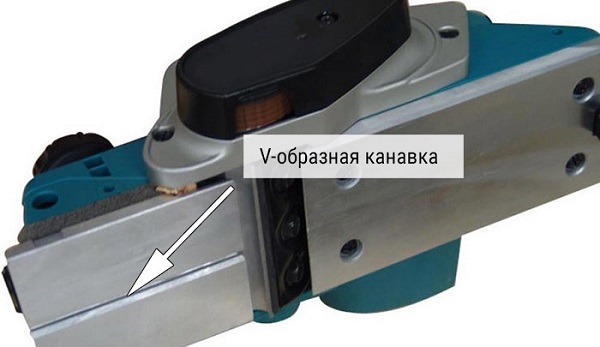

Presence on the sole V-shaped grooves allows you to create beautiful bevels on blanks. If only the planing of sawn timber is planned, then this structural element will not be in demand. Offset to one side of the location of the working drum makes it easier to choose quarters.

All additional functionality enhances the safety of work with the tool and ease of handling it, as well as partly productivity.

Tips for choosing an electrical chopper for home and professional use

Conventionally, the products can be divided into the following categories, which differ in the intensity of use of the power tool:

- household;

- professional;

- industrial use (premium).

The last two categories are of high quality and price. At its core, industrial power tools are also professional, only designed for almost constant work.

Electroplane Neu Balkenhobel Triton TPL180 Dreimesser

Tool for home characterized by:

- installed motor power up to 1000 W;

- inexpensive price (within 20,000 rubles);

- small weight (2.5-4 kg);

- revolutions of idling - 12-13 thousand per minute;

- optimal planing depth of 2-4 mm.

Household models allow you to fine-tune the depth of planing, but to pick up all the necessary accessories for them is problematic. It is also quite difficult to process hard wood.

One or two knives is the best option for household electroplane.

Electrical plane household PATRIOT PL 750

Professional tool it is intended for use on production or in woodworking workshops with the maximum load. It differs by the following criteria:

- increased power from 1000 W to 2200 W;

- a large number of additional functions (therefore, devices);

- wide grip of the treated surface;

- high speed of rotation of the drum;

- depth of planing 4 mm or more;

- high quality of the result (smooth surface);

- high cost;

- large in comparison with household models dimensions and weight (4-9 kg);

- drum speed without load - 15-19 thousand rev / min.

The width of the drum household and professional power tools should correspond to the most frequently processed parts:

- 82 mm - when working with window frames, chairs, racks, beams, planks of appropriate width;

- 110 ÷ 170 mm - when processing the surface of tables, cabinets, wide boards, doors.

The use of a tool with a width of the captured area of more than 110 mm is justified only when working with large sized lumber constantly.

If you have to work only with dried lumber, on the surface of which you need to remove minor irregularities, it is enough to purchase a tool with a planing depth of up to 2 mm When it is necessary to process boards or planks with bark, you need an electric planer with the ability to sample a layer of wood up to 1 cm thick.

As can be seen, there are significant differences between the performance characteristics of professional and household electrical planers. Knowing them, you can independently categorize this power tool.

Overview of popular manufacturers and models

A quality product review is based on the following criteria:

- the ratio between the performance of the product and its cost;

- reviews of ordinary customers and representatives of various workshops;

- conclusions of authoritative print and Internet sources, as well as individual experts;

- comparison of technical indicators of products.

The table below presents (by category) popular manufacturers with models of electric planers demanded on the market.

| Category electroplane to destination | Product manufacturer | Product model |

| Household | Makita | KP 0800 |

| KP 0810 | ||

| 1911B | ||

| Rebir | IE-5708C | |

| Skil | 1550 AA | |

| Bosch | GHO 18 V-LI | |

| GHO 15-82 | ||

| Dewalt | DW 680 | |

| Professional | Interskol | Р-110 / 1100М |

| R-110 / 2000M | ||

| Makita | 1806B | |

| Mafell | MHU 82 912710 | |

| Dewalt | D26501K | |

| Hitachi | P18DSL-RJ | |

| Premium Class (Industrial) | Mafell | ZH 320 Ec |

| ZH 205 Ec | ||

| Makita | KP312S |

For domestic use, you can also purchase the products of the companies Energomash, Hammer, Baikal (represented by 4 models: E312 AK, E313, E315 AK, E314), Fiolent.The lifetime of the equipment depends on the intensity of the work of this tool. Rarely on the market there are Diold electric planes and lesser-known manufacturers. Exact reviews about them are absent.

Electric plane on a tree Energomash RU-10110 with an emphasis

Professional products are distinguished by high quality from Hilti. Interskol products are considered optimal in terms of price, functionality and quality. Makita and Bosch are the traditional market leaders, products from which are distinguished by high reliability and useful additional features.

Makita KP0810 electroplane

All firms are constantly expanding the model series of their products, making the electric planer more productive and convenient in practical application. They strive to remain competitive in the market segment of this product. This allows you to choose the required parameters, as a universal tool, and more narrowly targeted products.

The vastness of the options turns the selection process itself into a rather difficult task. In addition to the criteria discussed above, it is recommended to consider the availability of nearby service centers company manufacturer of the selected model of power tools or the availability of its components in the distribution network. In case of a breakdown, this will allow solving a problem quickly with the help of specialists or independently.

/rating_off.png)