What is an electroplane

Woodworking craftsmen know what electric planes are: today it is one of their main working tools. The use of this analogue planer, equipped with an electric motor, significantly increases productivity, especially when planing boards or beams. It is convenient to handle it: you only need to set the direction, and the working effort is provided by the electric motor.

Content

Purpose of the tool

The electric plane is a tool whose main purpose is to level the surfaces of wood after the initial rough treatment.. As a result, lumber becomes smooth, various defects are eliminated from their surface, as well as existing irregularities.

Electrical plane was first produced by the company "Makita" in 1958. They were intended to replace manual planers.

Today, electric planers are supplied by a number of domestic and foreign manufacturers. Consumer goods from such companies are in demand:

- Makita;

- Bosch;

- Rebir;

- Skil;

- Interskol;

- DeWalt;

- Mafell;

- Hitachi.

For use in everyday life also purchase power tools from Hammer, Fiolent, Energomash, Baikal. In addition to popular manufacturing companies, other companies, for example, Diold, also supply electric planes to the market. But such products are much less common.

Area of use and functionality

For what else it is possible to use electric planes, besides planing, depends on their technical characteristics and additional capabilities. If the design features of the existing model of power tools allow, you can still perform the following operations:

- chamfer trimming;

- the creation of grooves in the blanks;

- processing of lumber and its fit to the desired size;

- quarter sampling;

- receiving protrusions on the edges of bars or boards (dowels), designed to connect them together.

That's not all, why do we need an electric plane. Its capabilities are not limited to this list of work operations. But they are in demand only from specialists: the majority of house craftsmen use devices mainly only for planing boards or bars.

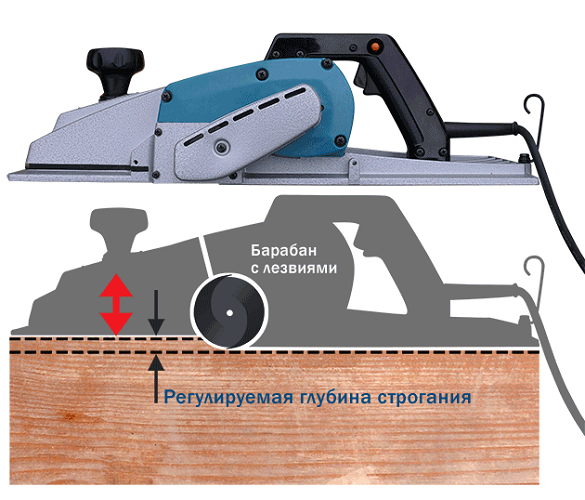

When planing wooden surfaces with the use of electroplanes there is the possibility of control over the depth of cut. This is achieved by adjusting the position of the sole (the front part) in height (diagonally and vertically) using a special handle or a button that has divisions. When this is achieved, the accuracy of the cutting depth when planing up to 1/10 of a millimeter.

Another useful feature of the electric planer is possibility of sampling fold or quarter. The operation is performed using an angle stop (ruler), which maintains a constant angle of 90 degrees between the power tool and the timber or board being machined. It also limits the planing area.Fixing on the right side of the depth limiter equipment allows the processing of sawn timber without cutting excess wood.

When straight knives are used in the work, the result is not fully satisfactory: a slight waviness remains on the treated wooden surface. Application for processing "spiral "cutting nozzles eliminates this disadvantage.

The finishing treatment of boards, bars and other wooden materials is often performed with a plane designed for grinding. With such a tool, the knives have a small precise stroke, which ensures a high-quality result. This allows not to carry out separately polishing of wooden surfaces.

Due to the presence of the lock button provides protection against accidental activation of the equipment. Also, the operation of the device makes it safer to start smoothly.

The use of different knives, as well as special devices expands the basic functionality of the electric planer. The presence of the nozzle makes it possible to attach a bag or vacuum cleaner that allows you to remove chips and dust from the treated area.This contributes to quick garbage collection.

Electric planer device

Knowledge of the device of electric planers, as well as their principle of operation, is necessary for everyone who uses this device or is only going to. This helps to properly use the tool, and also allows you to repair it yourself if necessary.

The device electroplane has not changed significantly since the first release of products of this type. Only separate functions and electronics in management were added. The installed electric motors were improved: they became easier, more power. Fundamental innovations are absent.

Electric planers consist of the following structural elements:

- enclosures;

- motor unit;

- bag designed for collecting chips;

- handles serving as a support;

- rubber linings;

- Soles (slabs), performing the functions of a support and consisting of 2 parts (adjustable front, fixed rear);

- a nozzle that removes chips generated during tool operation;

- trigger, enabling and disabling the device;

- lining (rubber);

- a lock button (when pressed, the equipment cannot be turned on or off);

- regulator that sets the depth of planing;

- drum with knives (their number can be from 1 to 3;

- side restraint;

- transmission mechanism.

The considered construction elements of the tool are depicted in the photograph.

The stability of the tool during operation depends on the size of the sole area. Its length for different models is from 30 to 40 cm.

For domestic use, it is enough to purchase an instrument, on the drum of which there is only one knife. For expensive models, electronic operating speed control unit, adjusting the speed of rotation of the motor shaft, depending on the size of the workload.

Features of battery electric planers

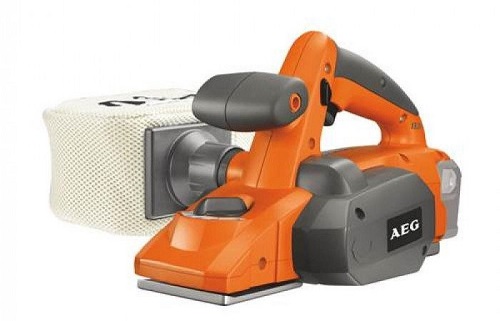

The general trend in the market of power tools to an increase in the segment of wireless (battery-powered) equipment is also characteristic of electric planers. Significantly increased power battery products, as well as their other characteristics closer to the parameters of stationary models, powered by the network.Wireless tools let you work safely. with increased air moisture. They are also indispensable in the absence of power sources.

Cordless Planer AEG BHO18-0

Wired tools are cheaper, and this is a disadvantage of battery models.

Almost all manufacturers of wired models also produce wireless counterparts. Their device is similar to wired models, only the power is supplied by batteries. Battery packs give a voltage of 18 or 14.4 V.

Designs of non-standard models

The specialists working with lumber are faced with a variety of tasks. To meet the needs of the masters, the manufacturers of electroplanes are constantly improving them, expanding the functionality. For this reason, a power tool of non-standard design, also in demand in the market.

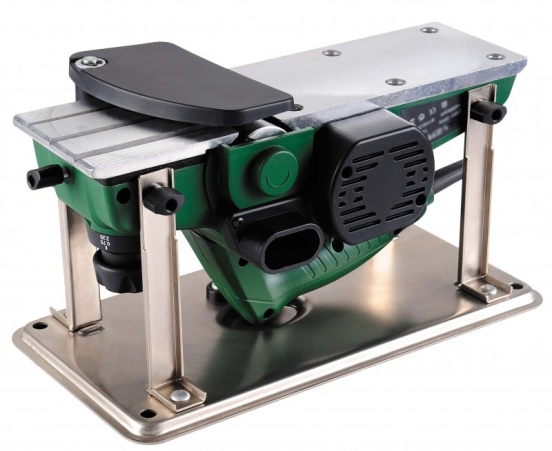

A number of manufactured models have a fixed installation option, when not a plane is moved along the workpiece, but vice versa. Such products have structural elements designed for rigid fixation of them in an inverted form. The created construction is similar to the small planing machine.

In order to chamfer up to 2.5 cm in depth, the design of the tool sole was changed: they made it in the form of a V-shaped notch. The result was fold models products.

By changing the design of the knives, we got products that allow us to process the workpieces with a total of very smooth surfaces.

To work on the surfaces of curvilinear shape, the metal sole of the planer was bent (its geometry was changed). This made it possible handle bulges with a radius of curvature greater than 400 mm and concave portions with a given parameter exceeding 450 mm.

In the modern market there are also other highly specialized versions of products. But they allow you to perform only individual operations. A review of the entire diversity of models is very difficult to perform, because new products appear regularly.

Principle of operation

The principle of operation of the equipment of any manufacturer is the same. The operation of the electric planer is based on the rotation of the rotor of the electric motor when the supply voltage is applied to the stator windings. Via gear mechanism (drive belt), the torque is transmitted to the drum, with steel blades located on its surface (their number may differ from different models, but usually there are two of them).

When the power is turned on and off, the motor starts and stops accordingly. Its overload during operation is eliminated by the use of a smooth adjustment of the speed using electronic systems.

Differences electroplane from the manual counterpart

The main structural elements of the manual and electric planers are the same. But the electric plane has the following differences:

- more complex from a technical point of view;

- it can be used only if there is a power source (battery or access to the network with a voltage of 220 V) due to the presence of an electric motor and electronics;

- working with him, you need to put less physical effort than when using a manual counterpart;

- high performance;

- another design of knives;

Figured knives for electroplane

- can be used as a surface gauge or a power planer;

- they can choose quarters;

- the final quality and accuracy of the work performed above;

- when working with the tool, planing occurs due to rotation of the drum knives, and not due to reciprocating movements by the plane;

- with its help it is impossible to process the corner and end parts of the workpieces, to level, and also to scrape the floors;

- due to the high speed of rotation of the drum increased the likelihood of injury when using this tool;

- the chips formed during operation are not removed through the slot at the top, but through the nozzle into a special bag;

- There is a possibility of adjusting the width of the strip that is captured when planing (using a side stop).

It turns out that electric planers differ from manual devices not only by increased practical efficiency of work and a more complex device, but also by a range of functionality, safety of use. Electric planers have high productivity when processing wooden surfaces compared to manual counterparts, but they should be treated with much more care.. They are widely used, both at the household level and at the professional level.

Practical use of electroplanes allows significantly save on lumber: buy cheaper rough, and then independently planing them.When buying these products, you should pay attention not only to their technical indicators, but also to take into account the manufacturer of the product, its price. It is better to give preference to tools from well-known companies, purchasing them in specialized retail chains where you can see the certificate.

/rating_off.png)