The principle of operation and the basic elements of an electric drill

Specialists in electrical equipment maintenance claim that an electric drill is the most popular tool. Today it is almost impossible to find a person who would never hear of her. Many home craftsmen use a drill not only for drilling holes, but also as a mixer for mixing paint or mortar during repairs. But we will tell about the device of the most ordinary electric drill and the purpose of its main components.

Content

Main components and parts

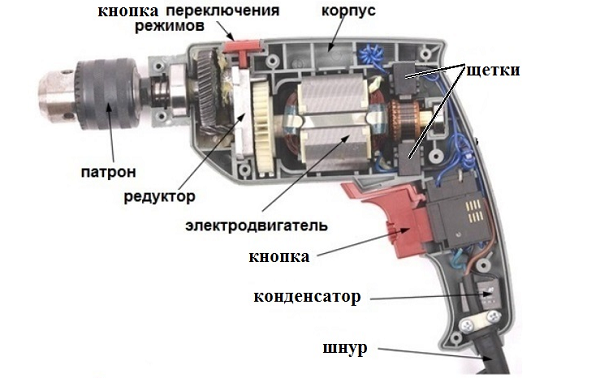

In principle, all drills have the same design - all components and parts are shown in the photo. Shock models have additional fixed ratchets, which, interacting with each other, force the drill to make translational-shock movements for drilling particularly strong walls of reinforced concrete.

Principle of operation quite simple: by pressing the start button, the user opens the current access to the brushes of the electric motor, which spins the rotor of the engine to the required revolutions. The rotational moment through the spindle is transmitted to the gearbox - it provides the rotation of the cartridge with a drill clamped in a special device. As a result of this interaction, various materials are drilled.

The principle of operation of any models of modern drills is identical, except for the specific nuances of percussion options.

Heart tool

The collector engine consists of three main parts: the stator, rotor and graphite brushes.

Stator

As a rule, it is made from special varieties. electrical steelwith a very high degree of magnetic insight. Structurally, it has the form of a cylinder with grooves where the copper wire winding is placed - there are two of them and they are located opposite each other. The stator is rigidly fixed in the housing of the drill.

Anchor

His second name is rotor, because he is in constant rotation when working tool. The anchor is a shaft with a core of steel similar to the stator pressed on it. Along the entire length of the rotor, special grooves are machined at the same distance into which its winding is laid. They are wound from solid copper wire, and bends are attached to the collector plates. The anchor is all divided into segments, its collector is rigidly mounted on the shaft shank, the whole structure rotates during operation on bearings mounted on both sides of the shaft.

The design of the rotor and stator is perfectly shown in the photo: a large ribbed wheel located on the shaft in front of the armature is a fan for cooling the internal parts of the electric motor.

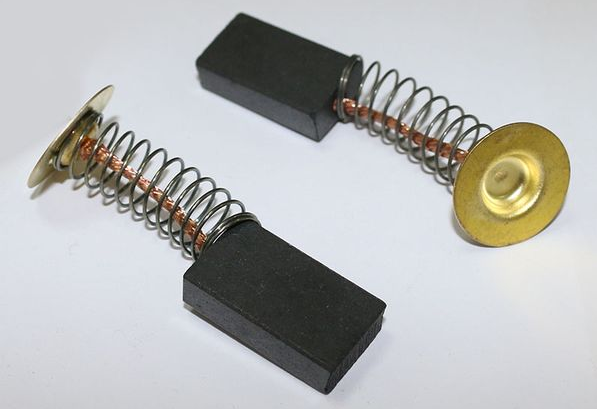

Brushes

The brushes are moved along special guides in the stator housing while the engine is running. built-in springs - they transmit the voltage to the rotor, therefore arcing constantly occurs between them and the armature body, indicating that everything is normal. During operation, the body of the brushes, made of pressed graphite, wears out due to constant friction,therefore, they are periodically examined and changed.

Triac regulator

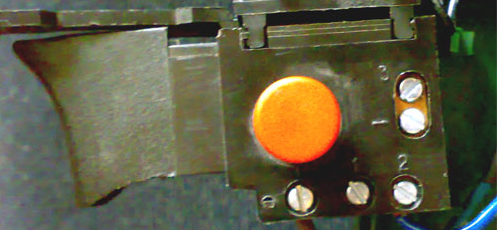

In a conventional drill design, this detail located in the start button. Visually, it looks like a trigger and acts in a similar way: when pressed, the drill starts and the drilling process takes place. With a strong pressure, until it stops, the engine rpm and the speed of rotation of the drill increase.

The adjustment scheme is simple: a regulator is assembled from a small number of parts using microfilm technology, located inside the start button on a special substrate made from a PCB. We will not dive into the jungle of technological nuances, since this question may be of interest to specialists, and not a simple user.

Gearbox

This knot of an ordinary one-speed drill intends for increase or decrease drill speed by increasing or decreasing torque. It is a gear type with one gear.

Some models have two speeds - there the gearbox has two gears and is somewhat similar to the gearbox in cars.

Types of cartridge

In practice, you can find only two main types of this simplest mechanism for fixing the cutting tool.

- Fixation of drills is carried out manually - there is one-footed cartridges, where the drill is clamped with one hand, and there are two-footed chucks, where both hands are already involved.

- The cartridge is tightened with a special key complex design. This is considered the most common type of chuck - used on all models of modern drills, especially in the powerful versions.

Functional nuances

Manufacturers of drilling tools are always trying to equip their products with exclusive options, so users today have the opportunity to purchase an excellent and very high-quality assembly apparatus. Here is a small list of the main innovations from the developers of modern electric drills.

- Electronic speed controllers. The latest models of electric tools are equipped with smart regulators, they are very convenient - the engine automatically shuts off in case of emergency, for example, when the drill sticks inside the hole. Then we turn on the reverse and pull out the drill - in this way the electronics prevent the engine from overheating.

- Reverse - with its help, the drill can not only tighten the fasteners, but also quickly unscrew it when dismantling.The regulator is located next to the start button.

- Impact mechanism. It is installed on special models, due to its use it is possible to drill holes in a particularly hard material. Impact drills can drill concrete and natural or artificial stone.

- Start button lock. This function greatly facilitates the drilling process - the finger of the worker does not get tired. The latch is located next to the button, it is very easy to use: one press, and the drill works in constant mode, a second press unlocks the trigger, and it turns off the power supply.

- Drilling depth limiter - a metal rod that rests against a part or wall and stops the drill depth at the desired level.

- Recently, there has appeared such a unique function as an additional workplace lightingThat is very useful in places with poor lighting.

Each drill is medium in size and power additional handle, which is installed immediately behind the chuck and helps the process: you can hold the tool with two hands and exert constant pressure on it with your whole body.

Battery model

Cordless drills are very popular with home craftsmen, because the work is not limited to the length of the wire, which allows their use in all conditions. They also apply to electric tools. There are options when the charger is located in the case for storing the instrument, and after work it is stored and simultaneously charged. Basically, battery-powered drills have two spare units, which are sufficient for work.

Such a replaceable battery is charged no more than an hour, so you will not take long breaks when you have planned a large amount of work for the day. As a rule, the charging unit is designed for several thousand times, but it is specifically necessary to recognize this indicator when buying, there are more expensive replaceable batteries, which charge in 15 minutes.

The cost of cordless drills is slightly higher than ordinary models.

Maximum efficiency

In the instruction manual, each manufacturer indicates rotation speed intervalin which the drill will make the most of its potential. For example, when working with wood, the highest speed is used, and for concrete and stone the mode is chosen more slowly.To use the drill as a screwdriver, choose the smallest revolutions.

With every detail of the device, you can spend some small manipulations that will significantly increase the efficiency of using the drill.

- Cartridge. When the drill is clamped in the chuck with a key, it is necessary to manually close the jaws to the stop, and then, moving in a circle, clamp them finally with a key. In models without a key that are increasingly difficult to meet the whole process is done by hand.

- Drill. This cutting tool must always be well ground, wear and tear, various damages significantly reduce its performance. The use of poor-quality drills can lead to the fact that the engine and gearbox will experience overloads that affect their service life.

- Reliable hold. This tool belongs to rather dangerous products, therefore in an operating time it is necessary to fix it well in hands. Vibration is transmitted to the body during drilling, so manufacturers add a second handle to conveniently hold the drill, which greatly helps control the entire process.

Special vents must be constantly open during operation in order for normal ventilation of internal parts to occur.

Types of drills

Today, the industry produces universal drills that can be used for drilling wood, metal and hard plastic. But sometimes you have to have special drills for a drill to quickly drill holes in concrete, ceramic tile, metal, to make large holes in wood, for example, to make a neat tie-in of a new lock on the door.

For this there are spiral and flat drills. Impact drills for brick and concrete, diamond drills for drilling in ceramics and large diameter circular drills for making holes in a tile to hold pipes for water, have proved to be good.

Extras

With the help of special devices for various purposes for the drill, you can expand the functionality of this universal tool. It is necessary to acquire them separately, but you will never regret about the money spent, because the special nozzles turn an ordinary drill into a grinding machine or a mini-sharpened for household needs. With help corner nozzles You can work with a tool in a hard-to-reach place or turn it into a metal cutter by installing a nozzle with the original name cricket.

Special guides make it possible to work strictly at right angles, for vertical drilling Special conductors or factory-made racks are used to turn a drill into a drilling machine.

No matter what model the user uses, it requires permanent care: after carrying out any, even the most short-term work, it is necessary to wipe the body of the product from trapped dust, paying particular attention to the ventilation openings - so that dust and minor waste from drilling do not fall inside the product.

If you are not going to use a drill for a long time, then all metal parts should be grease with a thin layer of technical oil - This will protect them from the effects of ubiquitous corrosion. Carry out periodic inspections of internal parts, especially for electric motor brushes - do not allow them to wear out to the utmost. If you follow these guidelines, your tool will not need repair in the near future.

/rating_off.png)