What are the guides for the drill consoles

Experts believe the drill is a very versatile tool for domestic purposes and professional activity - it can be used to install equipment and structures of any complexity, it is indispensable during repairs. To improve the quality and accuracy of the drilled holes, a drill guide is used, and we will talk about its various variants.

Anchoring options

The main task when fixing the drill in a stable position is the position of the cutting tool relative to the surface where drilling will occur. Working with a drill, without using special tools, it is quite difficult to make the necessary hole, especially of a large diameter. Difficulties await the home master when you need to drill hole at a certain angle - here without guiding devices can not do. Using various racks, the hand tool is modified in the original design of the drilling machine, and its quality directly depends on the correct selection of the rack.

In practice, there are two basic ways to turn a hand drill of any model into a stationary drilling machine.

- Drill stand or tripod - it is with their help that the product turns into a vertical drilling machine. When buying, the user needs to focus on the quality of manufacture, the absence of play in the moving system, and the material used to manufacture the guides. The base plate, which serves as a stand, should be massive enough and have a system of fastening parts for drilling.

- The guide attachment for the drill - This is a simplified version of the rack, experts refer it to the category of hand tools. This device rigidly fixes the drill and is characterized by excellent mobility. The difference is that with the guides you can drill not only what is between the fixed drill and the vice. When working with some guides, you can change the drilling angle.Of the negative features, only a narrow specialization can be noted, except for universal models.

In some models of the second option, a transitional cartridge is used, which is needed to use non-standard drill diameter - it increases the accuracy of the drill position over the part.

The guide system presented in the photo is considered universal, since it can install a rigidly mounted drill at the right angle thanks to the fixation system.

Rack parameters

If you have already chosen the best option for yourself, with the help of which the holder for the drill will be made, then you need to analyze the existing offers in the market to select the most reliable tool.

Important! When buying various models of racks, including vertical ones, you need to focus on fixing the desktop. Changing the distance from the tip of the drill to the material should occur by shifting the entire block with a fixed tool.

Consider what other rack parameters exist:

- bed dimensions;

- the ability to adjust the diameter of the landing neck;

- height of the equipment;

- vertical stroke - this parameter determines how deep the holes will be when drilling;

- distance from the desktop to the landing neck;

- the material from which the bed is made - cast iron is considered to be the best option due to its weight and due to its reliability during long-term operation (and the vertical stand where the landing neck is attached is made of metal or aluminum alloy);

- the size and weight of the entire device.

Factory versions of similar equipment are sometimes equipped removable clips for desktop, with which you can easily fix any part for drilling.

For drilling holes of small diameter, you should acquire a special design of the rack, which do not have a backlash of the drill during the working process.

KWB system

This system has earned enormous popularity due to the large range of functionality and low cost. Thanks to it, the exact position of the drills relative to the workpiece is achieved; it is distinguished by its low weight and size, which significantly increases its mobility and scope.

Separately, professional workers celebrate simple setup:

- angle of drilling with certain skills can be changed in the range of 0- 90 degrees;

- depth of drilling is adjusted by a stepless mechanism;

- V-shaped groove allows you to securely attach the workpiece of circular cross section;

- mounting neck has a diameter of 43 mm.

One negative caveat: for the correct operation of this unique device requires a solid practice. An alternative to this guide may be a design that uses hinge block - it is fixed on the edge of the desktop product and locks the part in the desired position.

Magnetic bed

The original design has a magnetic bed drill - it is designed for drilling, threading, can produce countersink and reamer old holes in the most unpredictable conditions. Its distinguishing feature is that it clearly holds on any metal surfaceTherefore, the main field of application of such mobile machines is the installation and construction using metal structures, industrial engineering and shipbuilding, the erection of prefabricated metal bridges, the laying of pipelines, the installation and repair of large tanks.

The base of the unique machine is securely attached to the surface of metal with a force of up to 5 tons due to a powerful magnet, allowing you to work in any position, even on the ceiling of the ship's hold.

The main advantage is the diameter of drilling, which is in the range of 1–150 mm, small holes are made with spiral drills, and larger holes are made with a crown-type drill. The weight of the machine varies from 9 to 25 kg depending on the model.

Other fixtures

So that the tool does not deviate from the direction of drilling, in practice, quite often special tools are used, called a jig - this is a system of holes a little more than the required diameter. For professional use, conductors are made of steel, and for use in everyday life - from durable plastic.

Conductor for drilling holes

Homemade drill stand

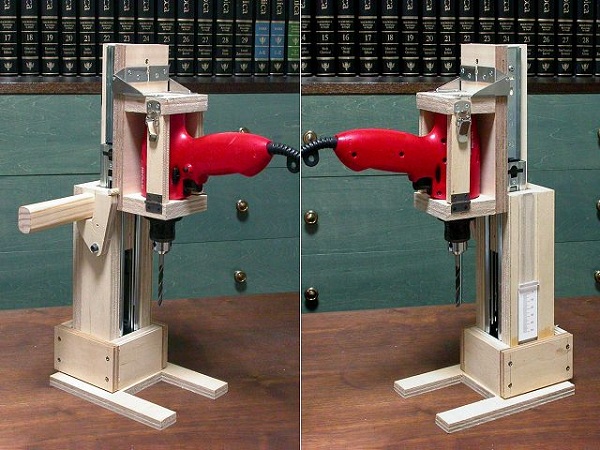

Many masters of garage cooperatives are not satisfied with the quality of the factory structures, so they make the bed for the drill in an artisanal way and with their own hands. Some craftsmen make clips for a drill completely made of wood and plywood - an example is shown in the photo.

/rating_off.png)