Assembling a mini drill with their own hands

The main purpose of the mini-drill - drilling of printed circuit boards, plastic, wood and some other non-solid materials. Compactness and efficiency allowed this tool to become one of the main assistants for the home master. And it is not at all necessary to buy a ready-made tool - a home-made mini drill does no worse than its duties than its factory counterpart.

Content

What can be done

You can make a mini drill with your own hands by using engines from various improvised means.

- Hair dryer This option is the most preferred, since the power of the motor from the dryer will be quite enough for the mini-drill to perform its basic functions. The maximum number of revolutions of such an engine reaches 1500-1800 rpm.

- Record player. Since the power of the tape recorder engine is very small, the only thing that can come out of such an undertaking is a drill for printed circuit boards. The engine is powered from 6 volts, which means that you will have to find the appropriate charger or battery.

Tape recorder engine

- Fishing rod reel. The mini hand drill can be made from a conventional reel for a fishing rod. The mechanism of the coil will be used as a motor and through rotation to drive the cartridge with a drill. The advantage of this method is ease of manufacture and no need for power from the battery or power supply.

Device manufacturing algorithm

The collection takes place in 3 stages. Let us consider in more detail each of them.

We make a mini cartridge

In order to assemble a mini cartridge for a drill, it is necessary to purchase a collet - a special mechanism for clamping cylindrical objects. Next, you need to connect the motor with the contacts of the future battery, which will power the device during operation.

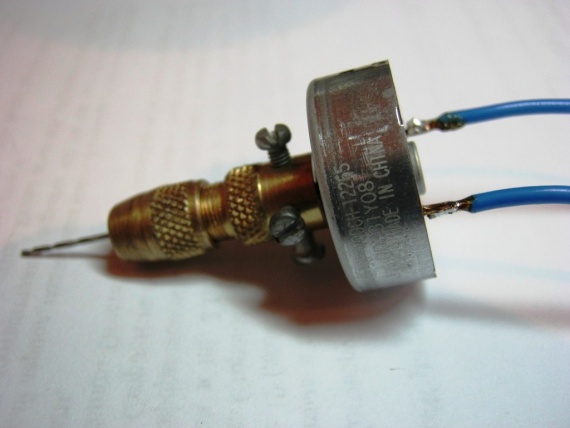

Clamp collet

If your drill is turning in the wrong direction - swap the location of the wires.

Find a drill of the right size is not difficult. Insert the drill into the collet body and clamp tightly. Next, the finished nozzle must be installed on the body of the motor. The collet should fit tightly on the motor shaft. Otherwise, you can not avoid vibration. Chuck on a homemade mini drill is ready.

Nozzles for homemade mini drills can be purchased at any hardware store. Before you buy, make sure that they fit the diameter of the collet.

Body preparation

As a case for a future device, it is possible to use both a capacity from under an antiperspirant, and a usual hollow tube of a suitable size. If you use a simple case hollow tube, it is necessary to cut the bottom and insert a rubber or other plug in its place. If you make a machine out antiperspirant enclosures, in the cover it is necessary to drill a hole to exit the drill.

We connect elements

On the reverse side you need to install the engine. If your motor does not fit in size - pick up another tube. Landing should be very tight to avoid vibration during shaft rotation.After that, it is enough to tighten the bolts on the collet and connect the device to the power grid.

One of the main disadvantages of collecting a drill with your own hands from a motor is lower power, compared to a standard machine, and low drill strength.

If a milling cutter is needed for your work, you can easily make it yourself from the old lighter. To do this, remove the twisting drum from the lighter and press it onto a suitable bolt. Secure it with a nut and insert into the collet hole. The surface cutter is ready!

If for any reason cartridge does not fit to the cylindrical shaft of the motor or coil, it is necessary to degrease it well and then put it on hot glue. This will help get a stable and durable construction.

Such a mini drill with acquired attachments can do the job of minor repair of technical equipment, drilling plastic, thin metal and making crafts.

/rating_off.png)