Do-it-yourself circular saw and other machines from the drill

Sometimes there is a need to cut a fairly solid board into several planks. Manually such work is not to be mastered, but to buy a factory circular machine for the sake of a single case is unprofitable. There is a very simple way out - a small circular is made from an ordinary drill.

Content

Design

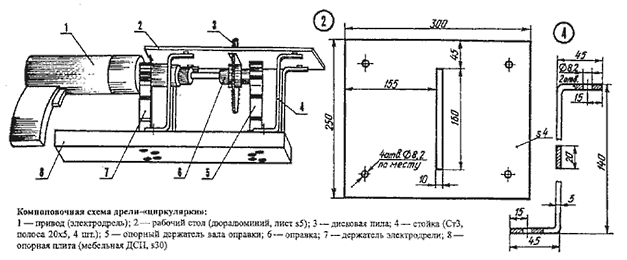

It is better to make the machine small in order to put it on the shelf when the need for its presence disappears. Its construction is extremely simple:

- the basis from a thick board or piece of a chipboard;

- working surface;

- racks;

- shaft with a circular saw;

- electric drive in the form of a drill.

The base is made of a sheet of chipboard 30 mm thick; it is enough to cut a piece of 300x250 mm in size. For desktop we choose a sheet of duraluminium 4 mm thick - it is rather hard and light so as not to make the whole structure heavier. In the right place we make a hole for a circular saw about 160x10 mm in size.

The holder for the drill itself can be made independently - all the necessary dimensions and drawings are on the Internet, but a similar design for the shaft with a saw can be purchased at a store or at a clothing market. Bearing shaft must choose dustproof - when a homemade machine will work, then there will be a lot of small waste in the form of wood dust.

The circular saw from the drill is assembled according to the standard scheme: first, all the details are fixed on the base, then the desktop is assembled and the drill is connected.

Security measures

When working on any machine, you must strictly follow the rules of the following rules:

- the place of the forthcoming work must be freed from unnecessary materials and tools;

- billets are fed smoothly without jerks and skews, so that the cutting tool is not jammed;

- the plane of rotation of the circular saw should be limited above the special protective casing;

- the machine must be kept clean and cleaned after each use;

- if the mini-sawmill is not used for a long time, then lubricate all metal parts with engine oil.

This small machine can cut not only wooden boards.If you install special cutters on it, you can process parts from brass and other non-ferrous metals, plastics or propylene.

Other homemade machines

Many users are interested in what else can be done with the help of available tools from the drill with your own hands? There are a lot of answers - home craftsmen are already doing various homemade products from a drill in garage workshops. Drill is a universal tool, so with a certain skill and imagination you can make everything your heart desires.

- Sharpened, you only need to purchase emery in the form of a circle and make a special holder in which the drill is mounted.

- Drilling machine - there are special holders for vertical drilling or stand.

- Turning machine small size for wood processing.

- Mini drill for various needs of the home master.

- To mow the grass around the garden without problems, you can do it yourself drill trimmer.

- Bulgarian from a drill done quickly, enough to buy specific tips.

- Garage car repairmen install the original winch for replacing engines based on old very powerful tools.

- Gardeners pave for planting young trees with homemade drill bit.

- When pouring the foundation for utility room in the private sector, some users use a homemade vibratormade from a drill to quickly compact a concrete structure.

Original devices

To continue the list of homemade products can be indefinitely, but we’d better explain in more detail about some homemade machines that can be made from any model of drill.

Drill

A drill from a drill is not a fantasy, but a real and fairly versatile machine assembled on its own. The main thing is to order from Chinese engineers (if you could not find it in your city) flexible shaft from standard medical unit. As a result, a drill appears in your arsenal, which can be used for engraving work or drilled with special hog holes in small parts or constructions, which cannot be used with a standard drill.

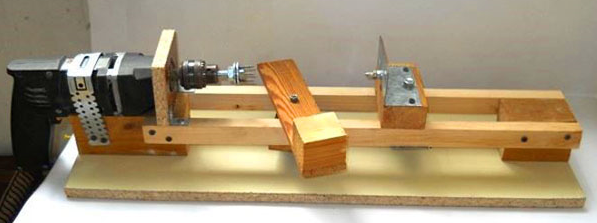

Lathe

Woodworking or lathe for the house can easily be made on the basis of the drill. The tool must be fixed with special clamps rigidly enough,insert a special design into the cartridge stick with several sharp pins holding the workpiece from turning. The center of the back holder (headstock) and the retainer in front of a homemade lathe should be located on the same axis. Accuracy is necessary to prevent beating during rotation of the workpiece. After installing the part, back grandma firmly fixed with a special clip.

The third element of the machine is handcuff in the form of a wooden block on which a chisel or other tool for processing the workpiece will be supported.

Important! When working on a lathe do not forget about safety, be sure to wear goggles, clothing sleeves should fit tightly forearm.

Turning machine for processing wooden blanks will work properly if the drill has a built-in electronic speed controller. By sampling, you set the optimal rotation mode for efficient wood processing. On such a woodworking device, you can make unique products for household needs: for example, a rolling pin or pestle with a stupa, a candlestick or a chandelier assembly.

Winch

The original winch on the basis of an old but powerful drill will become an indispensable assistant in the household, especially for those users who live in their own house and there is a garden plot. A simple situation: in the summer shower, you decided to install a more volumetric capacity, but raising it to such a height alone is problematic. Using a winch, this can be done in a few minutes. Only need to pre-calculate the weight of the tank and the speed of rotation of the spindle.

According to the garage masters, a homemade winch easily lifts the engine from the car. Watch the video if you don’t believe the word:

Experts advise to use an improvised device, installing a drill on the most minimum speed. This design can move objects with different masses, because craftsmen make winches even on the basis of an ordinary starter from a car.

/rating_on.png)

/rating_off.png)