How to repair grinder at home

The Bulgarian, being the most demanded tool in the house, is exposed to considerable loadings and an intensive use. Because of this, after some time it happens that when starting the engine jerks appear, the smell of burning and other malfunctions, suggesting that the angle grinder (angle grinder) broke. But do not immediately carry the device to repair or buy a new one. Most of the faults of this device can be resolved by yourself.

Content

Device and electric circuit of the grinder

Over the long years of the existence of such a tool as the LBM, its appearance, as well as its internal structure, has practically not changed. To repair the grinder with your own hands, you need to know the structure of its mechanical part, as well as the electrical one.

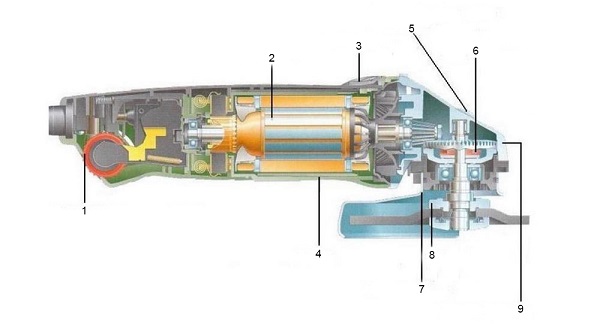

If you look at the figure below, you can see what parts of the LBM consists of.

- Wheel for adjusting the spindle gears of the unit.

- An electric motor consisting of a rotor and a stator.

- Start Button. Sometimes a soft start system is connected to it.

- The body of impact resistant plastic.

- Button for fixing the spindle (used when changing tools).

- Safety coupling. Protects the motor from overload when the tool is jammed.

- Protective cover It closes the tool and protects the user from flying particles of the material being processed, and also prevents injury to a person when the tool, for example, an abrasive disc, is destroyed.

- Nut, clamping tool. Unscrews with a special key that comes with a power tool.There are also quick-locking nuts that can be unscrewed without a key.

- Gearbox housing and the gearbox itself. It consists of a block of gears that transmit rotational motion from the rotor to the spindle with the tool.

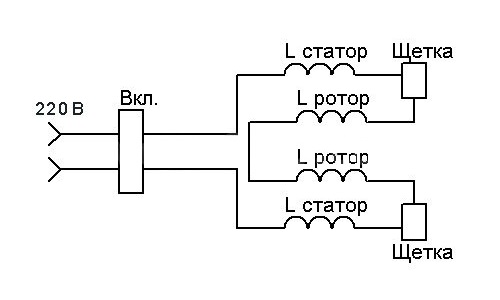

The figure below shows electric circuit of the grinder.

The electrical part of the LBM has the following elements:

- electrical cable with plug for electrical connection;

- start button;

- stator;

- electric brushes (carbon or graphite);

- collector;

- anchor (rotor).

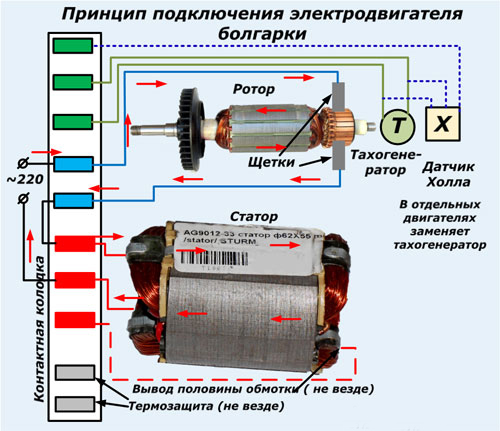

The following image shows Bulgarian connection scheme, namely its engine.

All components of the electric motor perform certain functions.

- Rotor - is a shaft on which coils and a collector are placed. The rotor, rotating in the magnetic field of the stator, transmits rotational motion to the angle grinder.

- Collector. It is a part of the rotor, to which all control cables are connected. Electrical signals from the control unit to the engine pass through the collector. It is connected to the collector electrical brushes.

- Electro brushes. Their main task is to transfer electric current from the power cable to the collector.

- Stator It is a coil with a certain number of turns. The task of the stator is to create a magnetic field, which, interacting with the anchor, sets the latter in motion.

The main malfunctions of the grinder and their causes

According to statistics, most cases of failure of angle grinders are associated with the electrical part of the apparatus. Some damage may be minor, which allows you to repair the grill with your own hands. But, for example, when the motor windings blow through, only the specialist can repair the angle grinder.

Bulgarian does not turn on

The reasons that the angle grinder is not included may be the following:

- defective electrical plug;

- defective electrical cable;

- the start button is broken;

- the contact between the power cable and the button is broken;

- breakage of the contact wire of the electrobrush;

- strong wear of electrical brushes;

- failure of the rotor or stator windings.

LBM does not develop momentum

The reasons that the angle grinder is not gaining momentum may be different.

- Breakdown of the speed adjustment unit. To check this version, you need to connect the engine of the device directly, bypassing the regulator, and check the operation of the device.

- Faulty electrical cable due to constant kinking or mechanical damage. Because of this, the damaged wire starts to warm up under load, and the engine speed drops.

- Dust collector. It is necessary to remove contamination with alcohol.

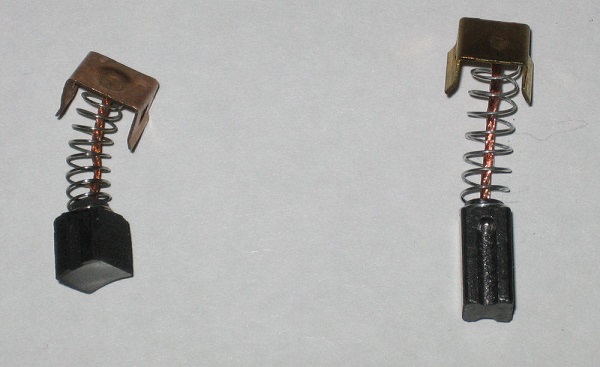

- Problems with brushes. They may wear out or have a short contact wire, as shown in the following photo.

The brush, although half erased, is quite workable. In this case, a short contact wire does not allow the spring to press the electrode to the collector. This situation may also be the reason why LBM stopped working in normal mode.

Electric motor is heated

The reasons that the Bulgarian is heated may be the following.

- Wrong device operation mode. As a result of overloads, the electric motor can become very hot, which often leads to burnout of the windings.

- Bearing failurelocated at anchor. As a result, the rotor clings to the stator, the engine is hampered, and the windings overheat. The problem is solved by replacing the bearings.

- Clogged ventilation ductsthrough which air enters to cool the engine.It is necessary to clean the ventilation holes from dust.

- Impeller failureused to cool the engine. It is installed on the rotor, on the side opposite to the collector. If the impeller is broken, it must be replaced with a new one.

- Interturn closures stator and rotor windings. You will need to rewind the coils or replace these parts with new ones.

Bulgarian sparks

If you notice a high sparking when you turn on the angle grinder in the place where the collector is located, then the reasons for this trouble can be the following.

- Damage to the armature winding: breakage of one or several winding sections, interturn lock. With such breakdowns, increased noise appears, the engine speed drops and the brushes burn.

- The contact between the collector plates and the winding is broken.

- Weak brush clamp. In the long-term regimes of the Bulgarian, the springs overheat and can “anneal”, while losing elasticity.

- Rotor imbalance of the engine.

- Violation of the cylindrical surface of the collector. This sometimes happens after rewinding, if the anchor is not pierced on a lathe, but is immediately installed in the machine.In such a case, it can also be observed that brushes will excessively sparkle.

- Isolation between the lamellae of the collector. There may also be a clogging of the grooves of the protropy with graphite or breakdown between the lamellas.

- Bearing wear, causing the rotor to beat, also causes brushes to spark strongly.

- Violation of the armature shaft geometry. Usually this happens when careless disassembly of the electric motor when the shaft bends.

- Installed graphite brushes of the wrong brand. Brushes are selected based on the expected speed and voltage.

- Raising one or more slats causes brushes to burn out quickly. This happens due to overheating of the engine during prolonged operation. As a result, the glass melt that serves as the reservoir base softens and the lamellae begin to rise. Due to the fact that the slats are raised, the brushes are erased very quickly.

How to disassemble the grinder for diagnosis

To diagnose the electrical part of the LBM, as well as to eliminate mechanical damage to the device, you will need to disassemble it. Disassembly is carried out according to the following algorithm.

- Using a key, remove the disk or other nozzle from the spindle of the unit.

- Unscrew the handle.

- Remove the protective cover.

- Open the special windows located on the sides of the casing of the angle grinder, and remove the electrical brushes, after disconnecting the terminals.

- Unscrew the gearbox housing from the engine of the LBM.

- Without much effort, pull the gearbox housing and disconnect it from the casing. In this case, the gear unit is removed together with the rotor.

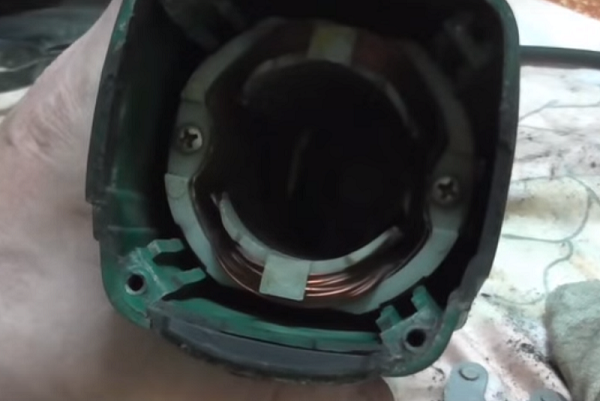

- After removing the armature, the motor stator will remain in the housing, which is also easily retrieved for diagnosis after loosening the fastener.

- To disassemble the gearbox, loosen the screws holding the cover. Removing the cover, you will see gear gear.

- To remove the anchor from the grinder, you need to unscrew the nut inside the gearbox.

- In order to remove the bearing from the armature, it is recommended to use a special puller. Otherwise, the shaft may be damaged.

Diagnostics of the electrical part of LBM

As mentioned above, most often the LBM refuses to work due to breakdowns of the electrical part of the unit. To properly diagnose the electrical circuits of the instrument, the electrical equipment repair technician uses a special device - a tester.

If you pressed the start button of the unit, and it does not work, then in 90% of cases the cause of the breakdown is not so serious that you could not repair the grinder with your own hands.

Experts advise to adhere to the basic rule of repair of power tools: move from simple to complex.

The first thing is required check of electric cable and plug at its end. If it is collapsible, unwind it and check the reliability of the contacts. Otherwise, you will have to disassemble the grinder (remove the device cover) and “ring the cable” with a tester, and also make sure that the current is suitable for the contacts of the “Start” button. If the device shows a break, then the cable should be replaced with a new one.

The situation when the current enters the button, but does not go further (when the position is on), indicates switch faults. The button can not be fixed. It must be replaced with a new one, but first mark the contacts to be removed in order to connect them correctly in the future. If the contacts are connected incorrectly, the motor winding may burn out.

If during the test it turned out that both the cable and the start button are intact, but no current flows to the brushes, then cleaning of contact plates of brush holders. In case of inefficiency of this procedure, the replacement of brushes is recommended. Further, if everything is fine with the brushes and the current flows to them, you should check the rotor and stator for short circuits and open circuits.

Check motor armature

The rotor of the electric motor may have the following malfunctions: inter-turn short circuit and breakage of conductors on the contacts of the slats. It is possible to check the anchor of the grinder with a multimeter: the device is switched to the resistance change mode, the value is set to 200 Ohms, and the resistance between the two adjacent lamellae is measured using probes. Thus it is required to check all pairs of lamellae. If the resistance values are the same, then the rotor winding is not damaged. Detection during the “ringing” of other resistance values, as well as the detection of an open circuit, indicates a fault in this coil. In this case, the need to repair anchors grinders.

Typically, a break in the conductors occurs at the junction with the winding. Inspect the places where the coils are connected with the lamellae, make sure that the contacts are soldered.

If you do not have a measuring device, you can check the rotor by using for this purpose 12 V light bulb and battery. Power should be in the range of 30-40 watts. The check is done as follows: apply voltage 12 V from the battery to the angle grinder plug, connect a light bulb to the break of one wire, start rotating the spindle of the angle grinder. If the winding is working properly, the light bulb will be on smoothly, without blinking. With the interturn circuit, the degree of filament of the spiral of the bulb will vary. In this case, repairing the anchor of the grinder with your own hands will be difficult, because the scheme of winding the anchor is quite complicated, and the process itself requires special equipment and knowledge. Therefore, this operation is recommended to entrust specialists. But the best way out is to replace the anchor on the Bulgarian with a new one.

If the light bulb does not light up when testing the rotor, this indicates the presence of an open circuit in the stator or a short circuit in its windings, as well as problems with electrical brushes.

Motor stator check

To check the stator of the grinder, use, as in the previous case, a multimeter. Values need set to 20-200 ohms and do the following. Touch one probe to the contact of the stator winding, and the second - to the body of the part.If the device shows resistance, it means that a breakdown has occurred on the case. Touch the probes to the contacts of one winding, and then to the contacts of another. If the resistance is the same, then the coils are OK. If the device shows an open circuit on one winding, it means that the stator must be rewound or a new part replaced.

Rewinding the stator at home, not having special knowledge, skills and equipment, will be problematic. It is better to turn to professionals who are professionally involved in engine rewinds.

Mechanical damage and their removal

Mechanical breakdowns of angle grinders include the following.

- Worn motor armature bearings. Usually when the bearings are worn, you can feel a strong vibration while the machine is running. In addition, there may be a rattle and other noises. Sooner or later, the bearing will still collapse, and spilled balls will fall onto the gears of the gearbox. If this happens, then in addition to the bearing, gears will have to be changed. Of course, it is better not to wait for this trouble, and at the first sign of a bearing failure, replace it. How to get to this part of the angle grinder, it was described above.

- Worn ball bearing or gearbox bearing. As in the previous case, when you turn on the device, you will feel the vibration and hear the noise, unusual for normal operation of the angle grinders. To prevent further damage to the gearbox, it is necessary to replace the defective part.

- Wear gear gear. Gears wear out quickly due to insufficient lubrication. For the same reason, the gearbox is heated. It is necessary to monitor the condition of the lubricant inside the gearbox and, if necessary, change it. How to disassemble the gearbox has been described above. The lubricant should be used specially designed for gearboxes of LBM, and you can buy it at the points where this tool is sold. If for any reason the teeth have broken at least one gear, then you need to change the whole set of gears (a pair).

Mechanical faults include breakage of the shaft lock. In order to replace the retainer, you will need to disassemble the gearbox and remove the large gear.

/rating_off.png)