How to choose and use the spray gun for painting cars

Professionals involved in car painting have the opportunity to choose a set of tools, focusing on the most frequently encountered tasks, their own habits and work experience. The beginner does not have such an opportunity. He needs to immediately buy a spray gun for painting cars, able to solve a certain range of tasks due to its features. Whether it will be a budget or professional device, pneumatic or electric, knowledge of the models, types and types of devices offered today will be solved.

Content

How to choose a successful model suitable for solving the problem

Choose a spray gun, which immediately will perfectly meet the needs and give pleasure when working with him - almost impossible. The problem is that the beginner often does not fully know all the subtleties of the painting process and cannot clearly formulate the list of requirements for the tool. However, there are several basic criteria by which a car spray gun is evaluated for the general level of reliability and convenience.

Reliable materials - the guarantee of durability

Choosing a spray gun for painting cars or other purposes - do not neglect the careful analysis of the materials from which it is made. Before buying it is worth considering all the details.

- The body of a good spray required made of aluminum. In models with increased reliability, structural elements are coated with nickel to protect against corrosion. You should not consider models whose case is made of silumin or other alloys that do not differ in high mechanical strength and resistance to acidic, alkaline media.

- The detail of the design experiencing maximum wear is the paint discharge nozzle. The minimum requirement that must meet a suitable for long service model - the manufacture of this element of aluminum. If you need a really reliable tool, you should stop the choice on the spray gun With a brass or stainless steel nozzle.

In general, the whole structure should be as light as possible, made of aluminum and steel, with a good starting stroke, which should also be made of metal. Saving every gram is a smart move.

Important! It is worth remembering that the total weight of the tool will increase significantly when the working mixture is poured into the colorful glass.

Another area of thorough evaluation - sealing degree. Automotive spray gun, regardless of its class, works with high pressure. Fluids must not leak. Therefore, special attention is paid to the quality of gaskets and seals. A good spray gun will offer reliable PTFE elements, technopolymers. High quality models are equipped with Teflon gaskets.

The location and capacity of the paint tank

Today, the choice of a spray gun for painting a car is proposed to be made among models with an upper or lower arrangement of a paint tank.Devices of both types have their own particular usage.

- Spray gun with top tank able to work with paints of high viscosity, requires to maintain a constant orientation of the tool for a stable mixture feed. The main feature of working with such models is that it is desirable to produce the entire volume of the glass. Its change is quite a long process, so it is not possible to quickly move from one paint to another.

- Spray guns with bottom tank will offer a quick change of paint. In such models the siphon method of paint supply is used. This imposes some restrictions on the level of its viscosity, but experienced painters appreciate the convenience of changing the glass almost without stopping the painting process.

Models with upper and lower tank differ in terms of weight distribution, ease of operation, overview of the painted surface. Beginners primarily appreciate simplicity. They prefer to buy for painting auto spray gun with a bottom glass. This model allows you to quickly change the paint, it offers a maximum overview of the painting area and the availability of all adjustments.

Available adjustments

Responsible for overall performance configuration of the spot of the torch and the flow rate of the coloring mixture. Therefore, a good spray gun must have at least two adjustments:

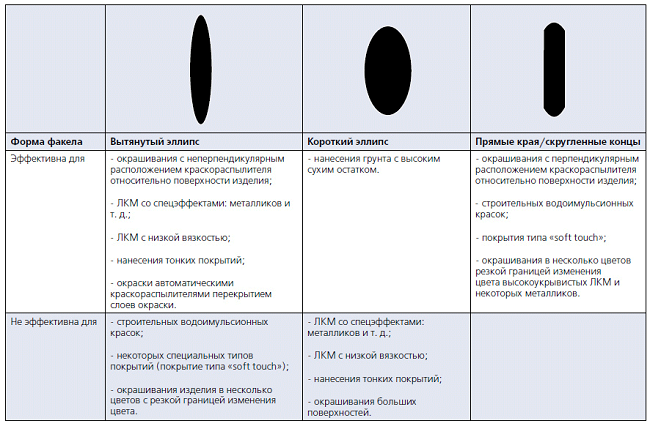

- setting the torch, in the normal position, the spot of paint has a round shape; by adjustment, one achieves an ellipse stretched vertically;

- change in needle position.

Professional tools often differ from the average spray gun for beginners. In particular, he has a longer needle stroke, the possibility of restricting its movement and fixing the position. It is also often offered the opportunity to fine-tune and conveniently adjust the size of the spot of the torch.

Specifications

From the characteristics of the gun directly depends on the list of works that can be performed with high performance. Also, the marking of the device can tell a lot about the mechanics of using the tool, the efficiency of the mixture consumption, the convenience of performing operations in restricted space

Nozzle diameter

The diameter of the nozzle allows you to select a device, focusing on both the types of dyes used and future work.

- Base coats, such as metallic or solid color, are best applied with an airbrush with a nozzle from 1.2 to 1.3 mm.

- For work with varnish and acrylic paints, including when finishing works - it is recommended to choose a tool with a nozzle from 1.4 to 1.5 mm.

- Primers with a sufficiently large grit (including acrylic type 2K) are best applied through a nozzle from 1.5 to 1.7 mm.

- Putty recommended work nozzle from 1.7 to 2.0 mm.

With the growth of experience and the emergence of tasks with specific requirements, the master begins to study the technical data of paints and choose the diameter of the nozzle of the spray gun. However, for beginners, an easier way is available. A fairly versatile, suitable for a wide range of tasks, the nozzle diameter is 1.4 mm. This tool can work with almost all paints, with some limitations to carry out priming operations. When using thick mixtures - they are diluted with a solvent, empirically selecting the consistency.

Differences spray gun on the working pressure and efficiency

The mechanics of the pneumatic type spray gun is quite simple.Air under pressure is mixed with the dye and is ejected in the form of a torch through a nozzle. Here are two key parameters. Actually inlet pressure, parametrics of the ejected mixture, paint consumption and efficiency of its use. Today on the market there are several standard classes of devices. The types of spray guns are marked:

- HP - high pressure;

- HVLP - high flow, low pressure;

- LVLP - low flow, low pressure;

- RP - with decreasing pressure in the mixing chamber.

Other markings and spray guns are, in a sense, derived - combining the properties and features of these classes. Such devices will be of interest to professionals to perform work with specific requirements. In particular, models of class LVMP (low consumption of medium pressure), MP (medium pressure), HTE (with high paint utilization ratio) are presented on the market.

HP system considered a classic. To buy a car for painting just such an airbrush is decided by people who are guided by the opinion of, so to speak, elderly paint masters. Such experts are accustomed to the tool of this class and do not pay attention to its shortcomings.

Airbrush pneumatic Wester FPG10-PL HP 55184

The HP system has a nice feature in the form of a wide spray torch. This tool is easy to apply uniform, thin layers of paint on a large area. High labor productivity is ensured. But the average amateur should pay attention to the main drawback: the paint sprayed under high pressure in the HP system creates a large cloud, the so-called spray. The working mixture just flies away into space, coloring everything around. As a result, the use of the HP system in a small area is inefficient economically - a huge percentage of paint is wasted.

More interesting for beginners HVLP system. Such guns emit the mixture under pressure of about 0.7 atm, requiring at the entrance about 2.5-3 atm. The system is characterized by extremely small particles of paint, a focused torch, a small percentage of spray. It provides not only high labor productivity, but also good indicators of economic efficiency. HVLP spray guns apply at least 65% paint to the target surface.

Airbrush pneumatic KRAFTOOL AirKraft, HVLP

But the most attractive for beginners is LVLP system. Such devices are perfect in everything:

- provide a neat torch;

- differ in the minimum spray;

- apply at least 65% paint on the target surface;

- require relatively modest compressor performance;

- react little to pulsation and changes in inlet pressure.

Important! Another attractive feature of the LVLP low pressure system is the ability to work in hard to reach places. Low consumption in combination with a neat torch allows you to increase the distance from the tip of the nozzle to the target surface by 50-100 mm.

Spray gun LVLP Huberth R500 (nozzle 1.3-1.4-1.7 mm)

RP system can be considered universal for the undemanding consumer. Spray guns of this type work with most varnishes, paints, primers, provide a wide torch, good performance and quality of paint application. The tools of this class have average requirements for the compressor; they can achieve excellent results when processing a large area.

Compressor Requirements

Beginners often make one standard error. Having a pneumatic compressor in the garage or workshop, they believe that its characteristics will be enough for any gun.In practice, this is not the case. Each device of a particular class makes its own demands on the supercharger.

- HP system will require up to 5 atm of inlet pressure and capacity up to 300 liters of air per minute.

- For HVLP the compressor should give 3 atm at an air flow rate of 360 and above liters per minute. At the same time, it is recommended to equip the devices with moisture and oil filters, since the supercharger has to work almost at the limit of its capabilities and continuously.

- LVLP system will require up to 2 atm at the entrance and pumping at the level of 150-350 liters per minute.

In order not to be mistaken in the choice and not to face troubles, it is recommended to find out the exact characteristics of the existing compressor before going to the store. Or buy a full set of equipment. There is another option: electric spray guns are quite popular among beginners.

Electric spray gun for painting cars

Electric spray gun - a fairly new device on the market. It is completely balanced, often automatic complex. For his work only need access to the power supply. All the necessary equipment (compressor, spray handle, colorful glass) is arranged in fairly compact units.

More recently, the main disadvantage of the electric spray gun called a large mass and low usability. But today models are being produced that deliver almost no inconvenience. The ideal option for a beginner is an electric spray gun, the compressor unit of which is hung on the backpack straps-unloading behind the back of the operator (or on the shoulder).

Separate models suggest installation of the supercharger on the floor.

Even more uncomfortable offer keep the compressor unit in hand.

Modern electric spray gun offers a number of convenient features:

- long continuous work thanks to use of the membrane compressor;

- high performance models with a piston compressor;

- high overall reliability and durability;

- a variety of range of used paints, varnishes, primers;

- high performance work.

In addition, the electric gun allows you to not fully use the working mixture and quickly change the capacity. You need to choose such a device according to the diameter of the nozzle, the available adjustments and the nature of paint consumption. In general - the tool of this class does not offer high flexibility and versatility,but allows using one device without complicated settings to carry out the necessary operations.

Manual for beginners: how to paint a car with your own hands

It is better to paint the car in a well-lit place, if it happens in the garage - there shouldn't be dust, cobwebs, dirt on the car. Stages of preparation for painting look like.

- The body is thoroughly washed out, all dust, traces of bitumen, and grease will be removed. It should only be used special solvents or white spirit.

- Bumpers, lighting fixtures, decorative elements, wheel protection in arches and other parts that cannot be painted are dismantled.

- The condition of the coating is being studied. All defects (chips, cracks) are marked with chalk or acrylic paint.

- In the marked areas, the paint is whipped off with a screwdriver to the metal, areas are smoothed with 60-80 grit sandpaper, ensuring a smooth transition to the intact paint surface.

- Defective zones are puttied. For this is used finishing mixture, it is necessary to smooth it, achieving a flat surface, as little as possible protruding above intact paint.

- After the putty has dried (according to the manufacturer's instructions), sanding from 120 to 600 is done, perfectly aligning the area of the defect with the surface of the intact paint.

Important! At the final stage of polishing, in case of excessive zeal of the contractor, additional application of a layer of putty may be necessary to level the surface.

Before painting, all unnecessary areas should be protected with masking tape, newspapers or tape. The entire surface of the body evenly sand 1200 grain to dullness. After that, carry out cleaning from dust, rubbing with White Spirit, followed by drying. Auto ready to paint.

- Enamel desired color should be diluted. The mixture is thoroughly mixed. Adding solvent, achieve the following result: after dipping a metal rod by 1-2 mm and removing the paint should flow at a speed of 3-4 drops per second. After that, the paint through the filter (for example, a piece of nylon stocking) is poured into the container of the spray gun.

- In most cases it is recommended to work a nozzle of 1.4 mm at a pressure at the inlet of the sprayer to 3 atm. Before applying the paint on the car is to ensure the uniformity of spray and adjust the torch. Setting the spray gun to paint the car is made on an unnecessary surface. After this is done staining.

- Correctly paint the car - starting from the roof. The gun should be kept so that from the nozzle to the surface of the body was 120-250 mm. It is necessary to apply paint in the movement, including giving when the spray moves and stopping it before reaching the final point of the trajectory.

- Paint on the car is applied necessarily in 2-3 layers, the interval for pre-drying between them is from 15 to 20 minutes. Only in this way, when working with your own hands, you can achieve a uniform, saturated and authentic color mark of paint. After the painting is completed, the car is left in a warm, moderately ventilated room with a temperature not lower than 20 degrees Celsius for 1-1.5 days.

Upon completion of the drying process, remove the protective films, newspapers, masking tape. The points of the screw joints filled with paint are carefully cut by taps and dies. After that, they install all previously removed equipment to their regular places and rejoice at the updated look of the car.

Conclusion

Beginners should not think that the only spray gun they bought will allow them to work with all paints, primers and special compositions. It is also impossible to perform absolutely any operations. The tool is selected by a number of parameters, focusing only on the basic work needed.If you do everything carefully and do not try to save - in the modern market you can buy a very convenient, durable and reliable spray gun, pneumatic or electric type.

/rating_off.png)