Choose the type of shuttle for the sewing machine

Sewing hook is one of the integral controls of the machine with a double-thread line. Among the modern models there are three main types: vertical double obeganiya, horizontal and pendulum. Strictly speaking, the type of the shuttle is not the only criterion for choosing a new device, but it is one of the indicators defining the area of use of the machine, its capabilities, potential. Let us examine the features of each type of the shuttle and find out which of them is better able to cope with its duties in the sewing machine.

Content

Pendulum shuttle is a simple solution for beginners.

A swinging or pendulum shuttle is found in economy class sewing machinesand also in obsolete old-fashioned models, for example, in The Seagull.Such machines are the best solution for inexperienced users, or for extremely rare uses. From the name it can be understood that the shuttle works on the principle of a pendulum, moving from side to side, grabbing a thread.

Swing Sewing Machine Shuttle

Pendulum type is quite reliable and unpretentious in work. If previous versions of this design were difficult to customize, then modern developments are free from such inconvenience. The main nodes of the shuttle device are tightly fixed, which eliminates defects in the seam: looping or gaps.

In brief, the swinging type is simple, inexpensive, and robust (resistant to minor overloads). Disadvantages of such a solution

- low speed line creation;

- excessive noise, vibration during operation;

- limited set of lines.

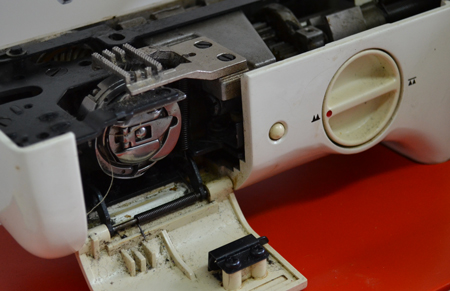

Double Shuttle Vertical Shuttle

Vertical shuttle double obeganiya, it is a vertical rotating or vertical rotary shuttle. It should not be confused with the vertical type described above, because the difference between them is very large. Rotating hook set, as a rule, in expensive professional sewing machines, and also in household the highest price category.

For example, the Japanese manufacturer Brother often implements this type in its technique.

The rotary shuttle node is what the “pros” choose, who sew daily for production purposes. Machines with such a mechanism are characterized by high speed, as well as impressive wear resistance. The quality of the seam is more than decent. If you comply with all the requirements of installation and configuration, various kinds of stitching defects are practically excluded, even taking into account the heavy load and long-term operation.

Vertical shuttle double obeganiya in sewing machines Pfaff

Experienced users only confirm the reliability declared by the manufacturer. The device will withstand any stress when working with a thin or thick cloth. Fully eliminated tangling of the lower thread. In addition, a sewing machine with a rotary shuttle has impressive range of different lines, as required by expensive devices for industrial or industrial purposes.

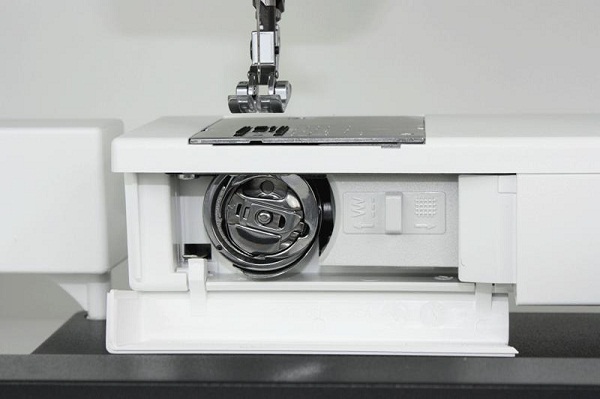

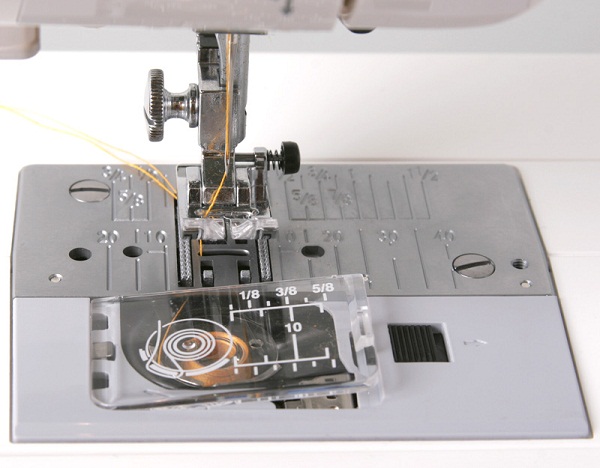

Horizontal shuttle

This type is somewhat different way of location and design. The working body is mounted horizontally under the needle plate and covered with a translucent cover. Sewing shuttle of this type does not have a bobbin case and is in immediate view. The user can control the rest of the thread, sees its color, the process of capture.

The thread itself is wound on a bobbin of durable plastic, other parts of the mechanism can also be made from it, which does not allow for negligence in operation. The key to durability will be the use of only recommended types of threads or fabrics. If the bobbin is relatively inexpensive and available for replacement, then the wear of the remaining parts of the shuttle will cost more and will require specialized repair.

Good to know! Rely on the experience of the majority and purchase replacement bobbins with the machine. They will always be on hand, which will eliminate the breakdown of work, because the problems with the equipment always occur at the most inopportune moment.

Horizontal shuttle in the sewing machine Janome QC 2325

Key advantages of the horizontal version of the shuttle:

- decrease in noise, vibration in the course of work;

- soft, high-quality line;

- setting the seam width without distortion;

- quick access to the bobbin, easy threading;

- the mechanism will allow to carry out linen loops of different widths,and in electronically controlled machines, loops with a peephole or rounded edges;

- average price category of sewing machines.

Among the shortcomings can be noted complicated setup. The adjusting screw is installed under the working plate, and access to it is somewhat limited. In addition, the horizontal shuttle in the sewing machine is whimsical and does not tolerate overloads, and the repair of the mechanism is not cheap.

Making the right choice

It should be noted that how the shuttle is equipped with a machine, despite the important role of this device, depends on its category. Conventionally, you can output a simple algorithm:

- household cars of economy class - vertical pendulum view;

- household machines of the middle class, whose functionality is wider than budget modifications - horizontal shuttle;

- industrial machines or expensive professional models for intensive work - rotary type.

It is rather a question of choosing the type of sewing machine, and the version of the shuttle node is only a consequence. This does not mean that you should not pay attention to this mechanism, because the algorithm described above is not a strict requirement, some manufacturers can move away from it. Among the described types of the shuttle for the sewing machine, you can choose the appropriate solution based on your own specialization.

- Users without experience in the sewing business, simple sewing machines with a pendulum shuttle are suitable. In such models the modest option and the reliable, hardy mechanism of a shuttle is combined. The same option will be a good solution if you are looking for a sewing machine for rare occasional use.

- If you need a car to create a small number of products from fabrics of different density, and sewing speed is not a priority - you should buy a model with a horizontal hook. Modifications of sewing machines with such a mechanism have good functionality, and their price threshold starts at about 8,000 rubles.

- Professionals or employees of small studios always make a choice in favor of a wide range of lines, high quality and comfortable work. Machines with such characteristics are most often equipped with a rotating vertical shuttle.

Top 4 most common misconceptions

Sewing equipment, like any other, is fanned by many different myths. Consider and debunk the most popular of them.

- Chinese-made mechanisms of poor quality. The stereotype was born in the 90s, but today this opinion is no longer relevant. Even the leaders of their industry are increasingly transferring production to China. First, it is profitable, due to cheap labor, and secondly, not every country can boast such production experience as China. In order not to lose, pay attention to the brand and the appearance of the product. Poor-quality "China" is characterized by the absence of a complete, competent description and passport, as well as an unknown brand.

- The horizontal shuttle is the best. Indeed, this type is today the most common, as it is implemented in the category of sewing machines, combining low cost and a wide option. Naturally, such machines are most in demand. The disadvantages of the horizontal type speak for themselves, and in the presence of finances it is better to make a choice in favor of expensive cars with a rotary shuttle.

- Why pay for the brand when there are cheap analogues. This is a popular misconception that leads users to buy cheap devices and an impressive array of lines and useful options. Perhaps, at first glance, all the machines are the same, but you can hardly find a quality and reliable device at a low price.If you have a sewing machine with a rotary shuttle and a large set of functions at an economy class price, do not be tempted, you will have to pay more for quality and reliability.

- The more expensive the device, the better the seam. Yes, a rotating sewing hook in an expensive typewriter will provide unsurpassed stitch quality, but under one condition - the correct setting. If the setting is incorrect, it does not matter which shuttle is installed in it, the result will not be the best.

Conclusion

The shuttle on your sewing machine is one of the key working bodies, and the quality of work and its range depend on it. In contrast to the predecessors of sewing machines, modern devices have become more functional, but at the same time more whimsical. They require the user to follow all rules of operation and maintain the device in a timely manner. Long service life will be provided to any type, no matter what you buy, but only with careful and competent treatment.

/rating_on.png)

/rating_half.png)

/rating_off.png)