Choosing a good overlock

Sewing overlock is intended, first of all, for processing fabric sections with overstitching seam, which prevents their shedding. The operation is necessary for the manufacture of knitwear, stretch or very thin fabrics at a professional level. Modern models of household overlocks may contain other useful options, which further expands their capabilities, and at the same time complicates the answer to the main question - how to choose an overlock for home. To make the right choice and buy the right device, it is enough to understand the principles of operation of various modifications.

Content

What is overlock for?

Many newcomers to the sewing business wonder why an overlock is needed, and why they use it. A set of programmed stitches in a household sewing machine does not allow to sew clothes professional quality, The only way out will be zigzag treatment or built-in tiling (overlock, knit) stitches. Upon closer inspection, the result is obvious: the overlock is much superior to conventional machines in the quality of the line, they look professional and smooth.

The possibilities of a highly specialized machine are quite attractive, especially for those who sew products from various materials. To understand what an overlock is, check out its features:

- overcast stitch;

- overcasting seam and chain stitch;

- flat seams;

- border;

- undercut seams.

All of these types of seams are used when machining or grinding parts from knitted, stretchy or loose fabrics. Experienced seamstresses are well aware that even the usual grinding of some materials can be a serious problem. This is where the overlock functions will be needed.

The lines created by the equipment are stretched together with the fabric; elastic or non-stretching threads, such as cotton or polyester, are used for processing or grinding.But unsuitable threads purchased for future use or for other machines will have to be postponed, which will extend the service life of the overlock.

Different models have in their "arsenal" different sets of lines, because they need to pay attention first of all. Simple devices perform 3, 4-thread stitches, but the models will make more expensive the excellent 2-thread lines needed for working with thin materials, or strong 5-thread ones.

Blade, built-in overlock, provides an opportunity to get a perfectly smooth, all-cut edge. Additional processing of the product after the overlock is no longer needed.

Overview of the main types of overlock

Overlok - the highly specialized equipment, is issued in several types. From the type of machine depends on the type of lines that it is able to perform. To choose the right device, you need to assess your needs and capabilities of different models. To decide on the purchase and how to choose the overlock, read their modifications.

On 3 threads

A simple 3-thread overlock is the most budget-friendly and affordable option; the model is designed for simple overlay lines:

- three-thread overstitched seam;

- narrow and wide obmetochny seams;

- flat seam or flatlock, including narrow or wide views;

- role seam (undercut) of 3 threads;

- border.

Pay attention to this type of overlock, before choosing a model suitable for work. They contain basic stitch setnecessary for making clothes or other products at the factory level. The absence of some options and lines that are in more advanced models does not always become a problem: not all users will need them.

On 4 threads

Semi-professional 4-thread models of the overlock make the front line with the second upper needle and carry out all the basic overlay stitches that are available in 3-thread modifications. Designed device for several purposes:

- grinding the edge of products from bulk materials;

- processing of knitwear or elastic fabrics;

- strengthening places where there is a heavy load during operation.

Often chetyrehnichtonye models get for sewing covers, clothing, swimwear or bags. In addition to the “base”, they perform the reinforcing line with the fourth string, the necessary for working with highly stretching tissues.

On 5 threads

The multifunctional 5-thread overlocker is one of the topmost: 3 threads go to an overcasting seam and 2 to a straight (or straight) chain line, which allows you to simultaneously grind and sweep the details of the product. The key advantage of the devices is a significant time saving when performing certain operations. A good five-thread overlock performs reinforcement and overcasting lines of five threads, as well as a chain stitch-braid, so necessary when working with knitwear.

On 8 threads

For home use, the purchase of such models is hardly justified, their intended purpose - industrial manufacture of clothing. As a rule, professional-level equipment has a wide range of possibilities: a thread cutter, the functions of a sewing machine, fully automatic adjustment of the thread tension and, of course, the highest build quality.

Overlock for home use or work in a small studio can be with 3, 4 or 5 threads. Their cost is relatively affordable, and the option justifies all the equipment costs. Which overlock to buy, of course, depends on the needs, but when it’s not worth saving, buy a model with the most affordable features.

Do I need a converter in the overlock

A special converter is a metal bracket mounted on the upper looper. It allows you to perform neat double-stitched seams and work with fine textiles. You can purchase the converter separately or pay attention to household overlocks with an already built-in part. When creating double-stitching lines, the thread itself is threaded only in the lower looper and needle.

Types of stitches available with a converter:

- narrow overstitched seam;

- flat seam flatlock;

- sub-role role seam;

- obmetochny three-thread seam.

The need for an option everyone decides for himself, based on the specifics of the work. You can buy an overlock at a low price, and buy a converter later, if there really is a need for it.

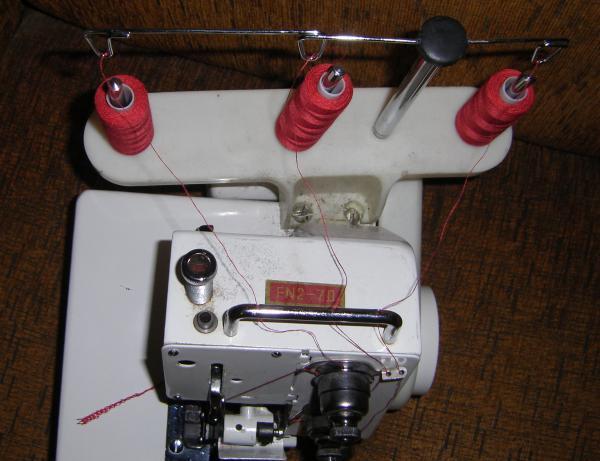

Converter in overlock

Overlock design features

Among the various options and design features, choose what is actually necessary for work. Some functions can significantly increase the cost of the device, but to be absolutely useless, their acquisition is rational only with appropriate financial capabilities.

- Chain Stitch Looper allows you to create an overlock flat 4 and 5 thread seams with parallel straight lines, that is, to use overlock for home sewing as a sewing machine. Still such devices are available to perform multi-line overlaying of the cut on the wrong side, grinding parts.

- Even small things ensure comfortable work, for example, color marking on guide. When working with different or identical threads, there may be some confusion, especially with prolonged concentration.

- Many cars are equipped automatic dressing lower looper, it reduces the time to configure and prepare overlock to work. Regardless of user experience, the option is indeed useful.

- Puncture force stabilizer It will be especially appropriate when working with dense tissues - it allows you to make the process of cutting a smooth and fast.

- Loose sleeve or the detachable sleeve platform makes the cuffs or low-leg workout quick and convenient.

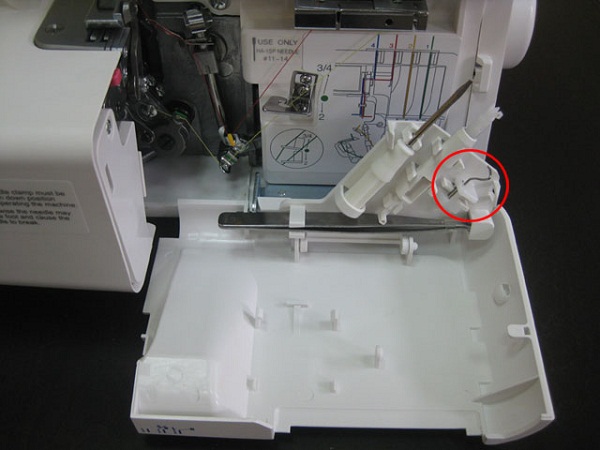

Free hose platform

- Thread tensioner adjustment. It is believed that the manual process is complex and painstaking, in part the way it is.Budget models have a panel with mechanical knobs on the front. If financial opportunities allow, you can pay attention to the overlock of the average price category. Their adjustment is located on the same axis, which as a result provides a good uniformity of stretch, inaccessible to cheap devices. The most expensive household overlocks are electronically controlled, the computer is responsible for the quality here.

Thinking about which overlock is better to buy, carefully study the functionality of different models. Be sure to make for yourself a small list of priority functions, which will make it easy to decide between several modifications.

Additional overlock option

In addition to the key functions, overlock can be equipped with additional ones.

- Disable blade. In the process of processing the edges of the product, the knife cuts off the excess, but this is not always necessary. For example, when working with very loose materials or fabrics of different densities, when performing decorative lines or when processing rounded parts.

- Experienced users are well aware of all the difficulties in working with knitwear, the fabric stretches, because of which the line looks poor quality: wavy and uneven.The differential conveyor will help to avoid marriage. The special regulator of the material feed can correct the speed of two ridges and completely eliminate possible difficulties. Another advantage of the differential conveyor is the ability to create assemblies.

51 overlock conveyor

- Adjusting the stitch length will allow you to optimally adjust the overlock when working with different fabrics, which will increase the productivity of work.

Perhaps, not all additional functions will be interesting to the user before purchase, but in the process of work, with experience, many of them will be appreciated. Saving time is a significant advantage for any seamstress.

Overlock, Coverlock and Sewing Machine

The task of which overlock to choose is not the only one that confronts the user. In the manufacture of certain types of clothing will have to think about additional equipment in the kit to the selected overlock. Stitching machine, in contrast to the overlock, only sews the edge of textiles in the folded form, performs a flat seam of 3, 4 or 5 threads. Such devices are not designed for trimming excess fabric and chain stitches.

A full-fledged sewing workshop, even at home, must contain an overlock and a sewing machine. The solution for many became carpet coverswhich combined in themselves both the first and the second device. In practice, it saves only space, but not cost. At the price of a pair, the overlock + spreading machine is approximately equal to the purchase of a single carpet.

The user is waiting for other possible troubles when choosing a combined equipment. The main thing is the difficulty in frequent reconfiguration of the machine, when in the manufacture of one product a quick change of operations is necessary. Such a decision is justified when the time of manufacture is infinitely tight deadlines.

From the point of view of convenience of work at the professional level, it is better to choose two devices, than one combined. Optimally to supplement a simple overlock with a carpetlock or a multifunctional one with a spreading machine.

When we choose a good overlock, you need to pay attention to the manufacturers. Today there are several leading brands, both Japanese and Chinese, whose products have already collected a lot of positive feedback.

/rating_off.png)