Features of the use of LED printers

The world of digital technology is constantly undergoing changes, focusing on the growing manufacturability, efficiency and speed of obtaining results. The production of printing devices also goes with the times. A few years ago, inkjet printing came to replace matrix printing (and is still popular today); along the way, more efficient laser printing technology has become widespread. Laser printers, with all their merits, were also repeatedly modified, which led to the appearance of another similar type of printing - LED. What is a LED printer, what is the principle of its work, and what are the main advantages, we consider in our article.

Content

A bit of history

The advent of LED printing technology was in the 80s of the last century. The development of this technology belongs to the well-known Japanese corporation Casiowhich was mainly engaged in the production of watches and projectors. In 1987, the very first LED device from another Japanese company, OKI, went on sale. The model was monochrome, that is, printed only black and white images. A little later, in 1988, actively developing OKI company already introduced a color printer, also working on LEDs. Then this new technology has become a kind of branch of the laser printing system.

OKI OL400 First LED Printer

However, it cannot be said that innovative development managed to move laser printers - they remained and remain the most sought-after and technological ones.

LED printers appeared on the Russian market of printing equipment only in 1996. It was then that the same company OKI opened its first branch in Moscow and launched the famous OkiPage4W model in mass production. Initially, this model was developed by the Japanese as a printer for home, but in our country it immediately began to be purchased in offices of small and medium-sized businesses. Initially not designed for large print volumes, OkiPage4W quickly became unusable.As a result, due to positioning errors this model, printers received negative reviews and general consumer disapproval.

In the late 90s and early zero, the production of LED printers began to expand: similar devices were launched by such large companies in the electronics world as Xerox, Panasonic, Epson and others. OKI Corporation, however, is considered a leader in the manufacture of LED-printers, confidently strengthening its position and becoming, thanks to the latest developments, a full-fledged competitor to laser models of printers.

Xerox-Phaser-3040 LED Printer

Principle of operation

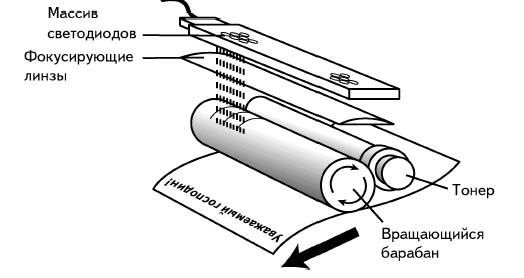

The principle of operation of LED printing is in many respects similar to devices with a laser beam. The key element of any MFP or printer is considered a part called fotovalo. Externally, the photovaly looks like a cylinder with a photosensitive semiconductor coating, where, depending on the light source, the electrical resistance varies. When a light hits one of the sections of the photo camera, it loses charge and begins to conduct electric current.

Principle of operation of the device

The essence of the laser device is that, under the direct influence of the source of illumination, the coloring composition (it is also called toner) is transferred to electrostatics by means of electrostatics, or, in other words, a photosensitive drum.Due to the same electrostatic effect, the toner reaches for a paper with a positive charge, where a primary picture is finally formed. Further, under the influence of high temperature (about 200 ° C) and pressure, the image applied by the toner is firmly formed on the paper. The light resource in the laser device is a laser beam.

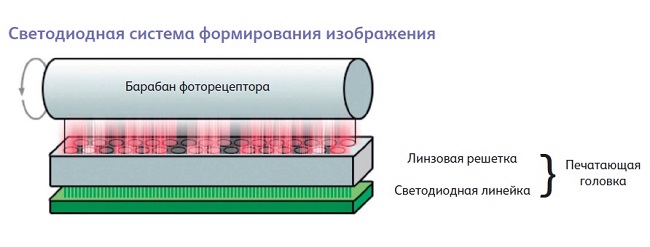

For LED printers, the main source of light is line of small LEDs, which is located on the entire surface of fotovala. LEDs can be a whole lot, for example, up to ten thousand pieces. When you turn on a certain number of LEDs, a spot illumination occurs, resulting in a primary image, or image imprint. Then everything happens exactly as in laser printers: using the electrostatics known to us, the coloring composition of the printer - toner “sticks” to the exposed areas of the photocell. It is then transferred to the paper with a “plus” charge and, ultimately, processed by high temperatures in the printer oven. After processing, the image is firmly fixed on paper.

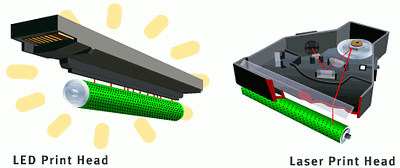

Thus, the difference between laser and LED printing technology is minimal: it’s all about the main source of illumination.. However, there is one important difference: the LEDs, unlike the laser, are fixed. The components of the laser MFP are in constant motion. The LED ruler is illuminated only at those points where it is necessary to expose the future picture. The result is a uniform exposure of the photo document, the image is clearer over the entire surface.

LED benefits

So what are the positive aspects of LED printing?

- Compact LED devices. The dimensions of the laser MFPs are much more impressive. This is not surprising: the LEDs and the entire LED ruler (print head) are very small in size, so they fit in a small package. To this day, even the first monochrome LED printers OKI are much lighter and more compact than the most modern inkjet and laser machines! The whole optomechanical scheme of the structure of laser printers with mirrors and prisms forms a rather weighty device in terms of dimensions.

Compact Color LED Printer OKI C301dn

- No moving parts. Since the LEDs, unlike the mirror, are completely immobile, the image lays more evenly on the sheet, and the equipment wears out at a lower speed.

- Ozone is not released during the process.. Triatomic oxygen is useful to the human body only in insignificant doses, and a large amount of it causes a toxic, toxic effect (dizziness, feeling unwell, weakness, etc.). Of course, modern models to the maximum prevent the release of harmful ozone into the atmosphere. However, in laser devices there is a beam which, rushing through a complex system of mirrors and prisms, strongly electrifies the air and contributes to the formation of ozone. In this sense, LED devices are completely safe: with the passage of light, the air does not ionize, and the light itself cannot decompose the oxygen of the air until an ozone molecule is formed. Thus, LED devices are highly ecological and do not harm human health at all.

- Image quality. Often the laser beam makes an uneven path through the scanning system: a different distance between the points is obtained when it hits the photosensitive drum. Therefore, the quality of the image in the center of the sheet of paper and along the edges can vary in quality, clarity and saturation, sometimes there are highlights.In LED technology over all points of the photosensitive cylinder are LEDs arranged in a linear row. The intervals between them are exactly the same, the size and shape of the point are also constant over the entire surface of the photosensitive cylinder. As a result, the image is quite uniform and in the center, and along the edges, a clear and well-readable picture is created.

- Print speed is higher. Since the diodes in the line are installed in the same slender row and light up at the same time, LED printers are able to work with intensive speed. In general, LED-devices are much more efficient in coping with the smallest details when printing. Laser devices register each line with a beam, which in itself is not a fast process. Also, laser printing has its own speed limits. If the speed limit is exceeded, distortion and fading may occur on the resulting image.

LED flaws

In any modern copying and printing equipment is found scatter of parameters. Manufacturers claim that in printers, the spread of parameters is about 15%, but in reality this value is at least 30%.With a resolution of more than 600dpi, the line of LEDs should consist of about five thousand elements. Ideally, everyone needs to develop a system to control the deviation of the brightness of the lighting. However, in reality this is unlikely, therefore, in the process of LED printing, saturation can either increase or decrease, which means that sometimes white stripes and gaps appear in the image.

Earlier, we noted a positive point in the absence of LED movement, however there is a drawback in this: with the LED line static, it is difficult to regulate the quality of the printing process.

Embarrassing and focusing individual LED elements, because the LED printing technology is more “jeweler” and miniature, unlike the laser. The laser technology applies the principle of long focus. Even if the optomechanical system is inaccurately adjusted, this will not affect the print quality. The long laser beam has a small cross section and does not impose strict requirements on the accuracy of the alignment of printed optics.

LED Printer Myths

Since the sale of LED devices in Russia began with a failure (the OkiPage4W printer did not win public confidence), several myths have emerged about them.

- LED printers are short-lived and do not work with a heavy load of pages. This is not entirely true. Printers and devices based on LED printing are divided into two main groups: models for amateur use and professional office ones. For a long time, it was believed that LED printers can print no more than 40 pages, while laser devices give out 100-140 pages in a maximum of 1 time. This is not quite true: modern LED-models have been dealing with large volumes of printing for a long time and are focused both on home use and professional needs.

- LED print quality is much lower than with a laser. When using the original consumables LED devices give a much clearer traced images with preserving the smallest details. At the same time, the use of original consumables significantly increases the cost of the print.

- LED road in operation. This myth is only partially true: original consumables and software are really expensive. Nevertheless, LED printers can work with universal consumables, and in general they will not undermine the user's budget, and they will last for a very long time.For example, Oki has introduced a lifetime warranty on certain models of LED devices - is this not evidence of a successful investment in technology?

Conclusion

Summing up, we can say that LED printers are a direct alternative to laser devices.. LED and laser printing technologies are quite similar: toner is applied to paper and then fixed under high temperature and strong pressure. Only the light source is different - in our case this is a line of alternately flashing LEDs. In general, the cartridge of the LED printer in its device is almost identical to the laser. Refilling the toner cartridge is also similar and, as a rule, does not cause difficulties. If you decide to buy an LED printer, decide on the purpose of its further use (for home or office) and carefully study the principle of operation. From his understanding, as well as proper care of the device will depend on the service life and quality of work.

/rating_off.png)