The best electrodes for inverter welding

In the course of performing manual welding using an inverter, rods specially made from metal or other materials, called welding electrodes, are used. Through them flows a direct or alternating current, sufficient to bring the edges of the welded parts to a liquid state. They can be made of refractory materials, like tungsten, but the absolute majority of electrodes recommended for inverter welding have melting core. If necessary, they are used for cutting metal, but the quality of the holes then remains low.

Content

Classification of welding electrodes of the melting type

Before starting work, the electrodes for welding with an inverter are selected in accordance with the material of the welded elements. Since the metal forming their basis fills the space between the parts in the process of formation of a seam, for better contact with them it should have a similar component composition and internal structure. Therefore, there are consumables for welding aluminum, copper, cast iron and other ferrous and non-ferrous metals.

The most widespread in the construction and industrial production steel electrodes, divided by GOST into several groups:

- for carbon and low alloy steels;

- for alloyed alloys;

- for heat-resistant alloy steels;

- for high alloyed alloys;

- for fusing additional outer layers with special properties.

Each product is based on a long cylindrical core, surrounded from the sides external coating. It is needed to protect the weld zone from harmful contact with oxygen in the air. The ratio of the diameters of the outer shell and the metal core distinguish products with a thin, medium,thick and very thick coating. There are four main types of coatings:

- the main;

- cellulose;

- rutile;

- sour.

Sometimes applied mixed coatings. Let's take a closer look at each type.

Features of products with different coatings

Electrodes with an acidic shell ANO-2, SM-5 are technological, easy to use and suitable even for novice welders.

Important! The oxides of iron and manganese in their composition adversely affect human health, so they should be used in open areas or in conditions of effective forced ventilation.

Rods with the main coating UONI-13/45, OZS-2, DSC-50 incorporate small crumb of natural rocks: marble, quartz sand, fluorspar. The mixture is fixed using liquid glass, so it does not have a harmful effect on personnel. The seam obtained with the use of such consumables has a high ductility. They are widely used for the installation of the most serious structures and laying of pipelines operating under high pressure.

Rutile welding electrodes for the inverter ANO-3, OZS-4, MP-4 as a part of its coating contain safe rutile. It gives a small amount of slag, which almost instantly hardens in the form of a thin film.These qualities allow you to weld parts at any position of the rod.

Products cellulose coated WCC-1, OZTs-1 contain organic compounds, ferroalloys and talc. They also provide high-quality seam in all directions of welding from any side of the part and give good results when joining thin sheets. Their only drawback is the fragility of the seam.

Electrode selection by core diameter

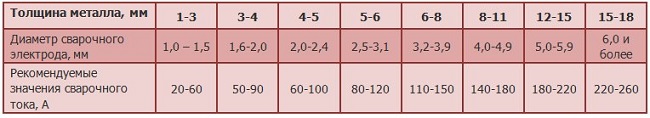

The most important characteristic of the electrode is the diameter - it should be selected depending on the thickness of the sheets to be welded. It is directly related to the required value of the current consumed by the inverter. The thicker the penetration depth, the more massive the core is needed and the higher the strength of the current is established. The table below shows the relationship between the diameter of the electrode, the thickness of the metal and the recommended amperage for welding.

The most popular sizes are 3 and 4 mm. When laying thick-walled pipelines and installing large metal structures, consumables of 5 or more millimeters are used. For welding thin metal is better to choose a miniature wire.

The most common brand of electrodes and their scope

It is impossible to compile an objective rating of electrodes for welding with an inverter, since all of them are developed for various metals and conditions of use. This takes into account the recommended working position of the rod, the nature of the coating, which polarity is constant or reversible when setting the welding machine. Strong influence on the choice and individual preferences of the welder, folding in the process of many years of work. We will present the most common brands in the environment of welders, which enjoy well-deserved popularity for more than one year.

MP-3

Rutile electrodes of this brand are among the most common and popular. They are designed for welding. carbon and low alloy steels with maximum breaking force up to 490 MPa. With their help, it is possible to cook parts with an inverter up to 2 cm in size. For this purpose, an alternating or direct current source of reverse polarity with an open circuit voltage of at least 50 V is used.

- ease of ignition and exceptional arc stability;

- slight spatter of steel;

- the ease of creating a solid and even seam, available even to a beginner;

- simple separation of slag crust;

- high performance;

- minimum quality requirements for edge preparation;

- possibility of welding at any position of the electrode.

- a large number of manufacturers of products of this brand, among which are found and unfair;

- a strict approach to storage conditions, due to a sharp deterioration in the operating parameters of the seam when the rods are wetted.

OZS-12

Another member of the family rutile electrodesWhich is well suited for welding low carbon steels. The excellent strength of the seam with the absence of extraneous inclusions and the tendency to cracking in a wide range of thermal conditions and external loads is required in the manufacture of complex structures on potentially dangerous objects. You can cook them with direct and alternating current, while using the minimum possible power.

- excellent weld quality;

- any direction of the rod during the welding process;

- instant ignition and steady arc;

- possibility of welding with minimum currents;

- ease of cleaning of a seam from slags;

- low cost.

- increased susceptibility to moisture, which requires mandatory electrode tempering before work at 150aboutC for an hour;

- the need for careful cleaning of the weld area before starting work.

OZCH-2

Electrodes with a sour coating, designed for welding of blanks from gray and ductile iron and elimination of casting defects. A direct current of reverse polarity is established on the welding machine. The seam is made in the lower horizontal plane or in the vertical direction when moving from the bottom up with short rollers with periodic forging and cooling.

- opportunity cast iron welding - one of the most capricious in the processing of materials.

- complex production technology;

- you have to withstand the consumable part in a muffle furnace for one hour at a temperature of 190-210aboutWITH.

SSSI 13/55

The best electrodes for inverter welding of the most complex and high-quality products made of carbon and low-alloy steel have main type of coating.

They are highly valued by professionals for the excellent quality of the seam, but require some time to get used to work with them. Provar lead a constant current of reverse polarity in almost all positions. The only exception is the vertical seam in the direction from top to bottom.

The permanent connection can withstand considerable loads and can be used over a wide temperature range.

- uniformity of the seam, ensuring the use of products of this brand in the manufacture of critical pipelines and loaded building structures;

- simple slag removal;

- high performance;

- economic consumption of electrodes;

- a wide range of possible spatial positions of the rod;

- acceptable cost.

- the complexity of re-ignition;

- the need to get used to a rather complicated arc maintenance mode.

OZL-8

These electrodes with basic type coating are applied for work on a stainless steel. At the same time, the material of the seam perfectly transfers the influence of chemically active media and is not afraid of high mechanical loads. Welding is carried out in an arbitrary position with direct current of reverse polarity.

Such electrodes are used in the manufacture, installation and repair of devices and pipelines in the food, chemical and petrochemical industries. The seams received with their help maintain extreme temperatures and high blood pressure.

- high quality seam;

- wide range of applications;

- steady arc;

- simple welding mode in all positions;

- minimum amount of slag and ease of its removal;

- reasonable price for products of the class.

- the need for preliminary calcination of electrodes at 300aboutWITH;

- increased material consumption.

Conclusion

If you are going to buy electrodes to perform a certain type of work, it is advisable to carefully familiarize yourself with their technical characteristics and scope. Experienced welders try to use minimum set of stamps, giving preference to one or another producer, which reduces the risk of acquiring a defective batch.

/rating_off.png)