Sharpening tool on elektrotochile

Anyone who has a garage or a private house is forced to do repairs, during which various chisels, axes and other cutting tools are used. It means that the electric grinder can always be used: this tool is perfect for sharpening knives or scissors. It is useful if you need to sharpen a shovel, chopper or other garden accessories, make a screwdriver edit. In your own workshop, you just need to have such a power tool. However, having it and being able to use it is not the same thing.

Content

What to sharpen tools

To properly sharpen knives on sandpaper, you should know the basic principles of sharpening. But before proceeding with the sharpening of the tool, it is necessary to figure out what kind of electric torques there are, and how they differ.

On sale are the most common mechanisms made in China. They have two stones from different sides: one is coarse, it is used for processing heavily blunt tools, and the other, with a fine abrasive, is used for dressing or grinding the cutting edge.

The advantages of such a device include a relatively low cost, and the disadvantage is the high speed. To work on this device requires a lot of experience. If not, then sharpening a knife will turn into anguish. The cutting edge will be wavy, and marks may appear on the blade. This indicates overheating of the metal during processing.

The stores are sold and universal machines, but their cost is much higher. They have a gearbox, which reduces the speed of the stone to 125 rpm - this allows not to overheat the metal during processing.

When straightening knives with a thin blade occurs, overheating of the metal can completely ruin the cutting tool.

More expensive machines have a drive on the grinding belt, changing which, you can not only fix the blade, but also polish it. Sharpening a knife with an electric grind with such devices will be easy even for a beginner.There is less chance of overheating of the cutting edge and there is no urgent need for cooling.

How to sharpen knives on sandpaper

Sharpening a knife on an electroshield is a rather difficult operation. To get a good result, you need to know some details.

- First of all, you need to carefully consider the blade. We pay attention not only to how bluntly it is, but also to the fact at what angle sharpened cutting edge. During the work it is necessary to maintain the specified angle of sharpening. In this case, help a special device that allows you to change the angle depending on the tool to be sharpened.

- If a preliminary operation is needed, which is performed on a rough abrasive wheel, then the cutting edge is positioned to meet the movement of the stone. When doing polishing work, the cutting part should be located in the direction of rotation of the stone.

- During sharpening, the blade is gently moved from side to side. You should constantly make sure that the entire surface of the edge was processed evenly.

- Before starting work, it is determined by what kind of stone it is necessary to perform the operation.For heavily blunted blades, coarse abrasive wheels are used first, and then they rule on the shallow ones.

- Working with high speed grind, be careful not to overheat the edge. Otherwise, you can ruin the knife permanently. To avoid this, the workpiece is periodically cooled, dropping it in a bath of water. Also it is impossible to strongly press the part to the abrasive.

The presented video is a good example of edge processing on a machine using a mandrel:

You can also perform more complex operations on an electroshield, for example, make descents on the knife. This work is carried out with the independent manufacture of cutting tools. They may have different geometry, depending on its purpose.

It is impossible to pierce sandpaper runs without an appropriate mandrel. Descents can be straight or concave. Special devices are used for their manufacture. They are made independently, since in the trading network, due to low demand, they come in limited quantities. An example is shown in this video:

Application of a sharpener for straightening cutting tools

At the electrosharpen make sharpening of various tools used in the carpentry: chisels, chisels, etc. To make the cutting edge sharp, use a special fine stone and low speed sharpened.

The correctness of the angle of the cutting part is checked on a special template.

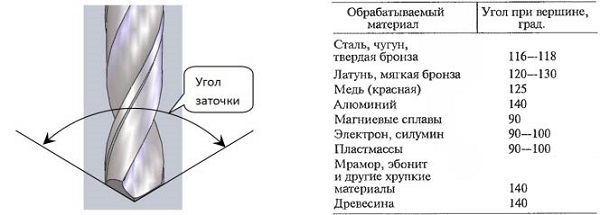

Working with steel structures, where a lot of drilling is required, there is a constant need sharpen metal drills. In this case, the master needs to know at what angle the drill is tucked. Each material has its own hardness. Approximate values of sharpening angles for different types of materials are given below.

To properly sharpen the drill, apply a variety of devices that hold it at a certain angle to the abrasive wheel. How these devices look is shown in the photo below.

It would seem the easiest operation - sharpen an ax. It is difficult to overheat, as it has a significant mass of metal. But there may be difficulties.

- For each operation performed with an ax, a certain angle of sharpening is required. So, for working with fresh raw wood, it is 20 degrees,and for hewing dry wood - 30 degrees.

- Sharpening an ax on an electroshield overheats the metal of the blade, which leads to an increase in its brittleness. When working, such an ax will be quickly re-blunt.

- It should sharpen the ax at low revs and eliminate the beating of the abrasive as much as possible.

- Use a water cooled electric sharpener or constantly lower the ax into cold water.

- You need to sharpen an ax by holding its blade against the rotation of the abrasive disc. The butt should be placed at an angle of 45 degrees with respect to the circle.

Working with electric grind should observe safety. It is impossible to use a sharpener without protective covers: an abrasive wheel can explode and injure during operation. It is also necessary to use eye protection against scale and sand.

/rating_off.png)