All types of cutters and accessories for manual milling cutter

The milling cutter is a cutting tool with which a manual milling machine or a stationary unit can process the surface of various materials (wood, plastic, metal). Since the equipment is designed for rotational motion, then the basic form of it will be disc-shaped or cylindrical. At the same time, the cutting edges of the tool can have a rather intricate shape. Mills for a manual milling cutter are divided into several types. The most common among them - for processing wood. At the same time, wood cutters also have their own classification. Consider what types of cutters are designed for processing wooden surfaces, and how to choose them correctly.

Content

Grooving cutters

If needed select groove any depth and width, then for this purpose the groove cutter is the best fit. Its design allows this operation to be performed both on the face (face) of the part and on its edge. The grooving cutter is mainly used when joining parts to a spike. Also, using nozzles for a wood milling cutter that follow a ruler, it is possible to cut even grooves of any width.

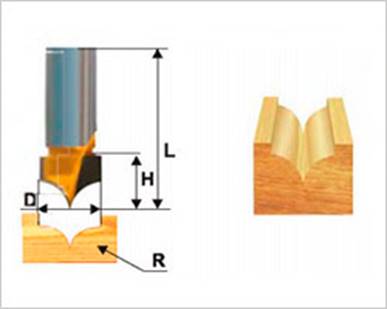

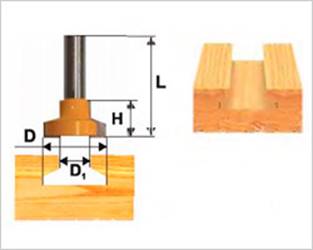

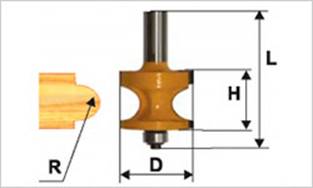

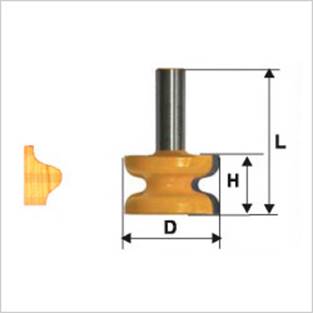

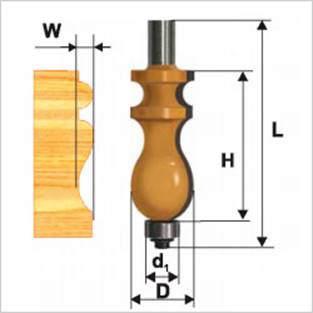

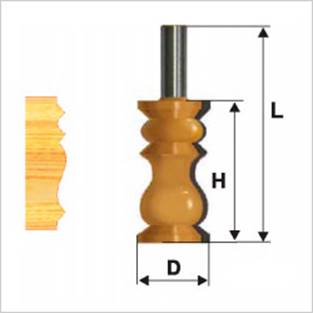

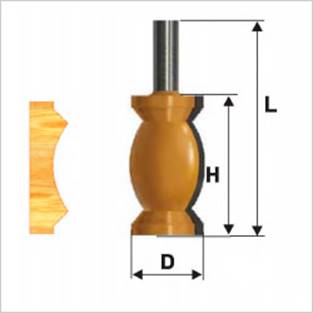

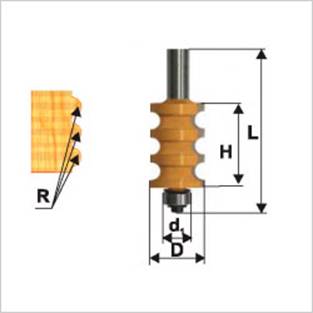

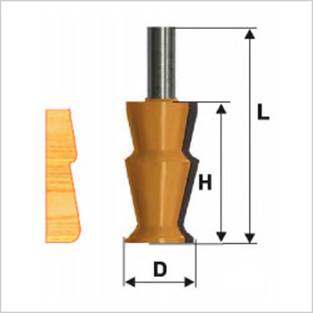

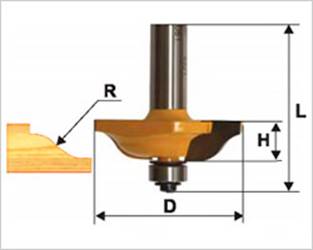

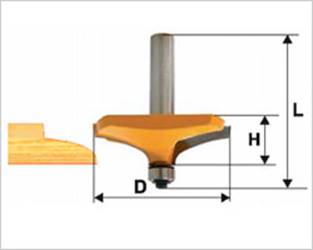

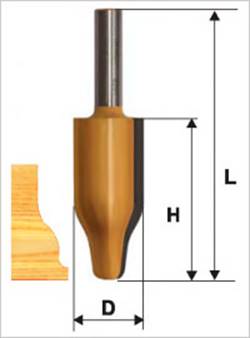

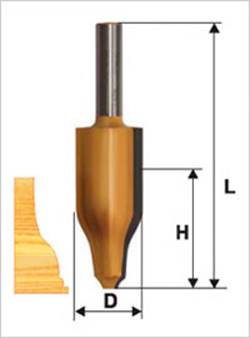

Shaped

Allow to give a groove certain shapes similar to braces. The tool selects not only the grooves inside the workpiece, but also changes the shape of the edges of the edge. Making a complex pattern on the surface of the workpiece, it is first made to pass through it with a straight cutter (slot). In the future, this simplifies the centering of shaped tooling.

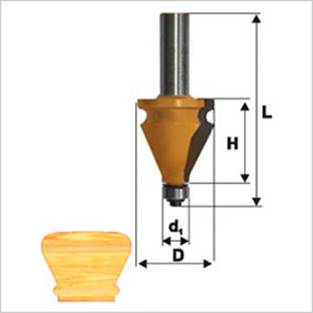

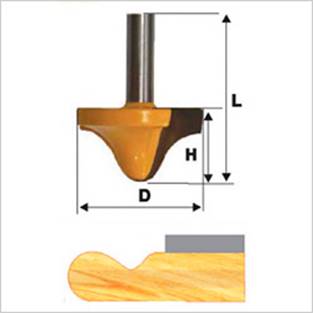

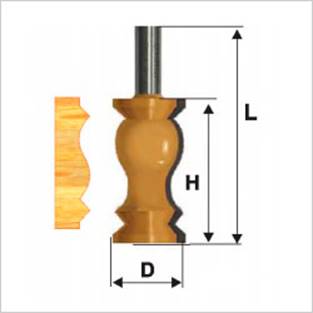

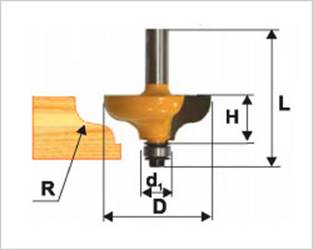

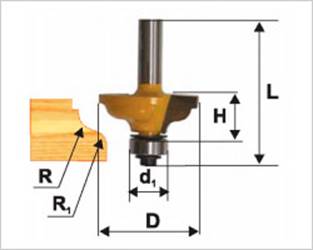

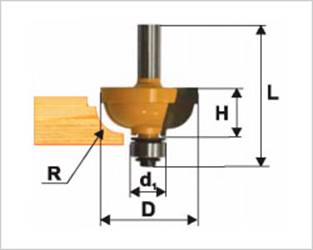

The following figures show the main types of grooving cutters.

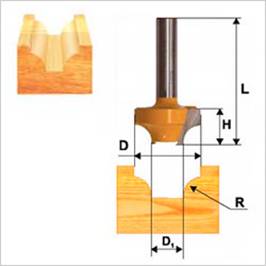

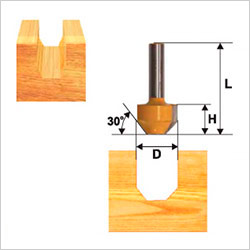

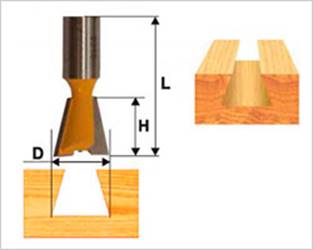

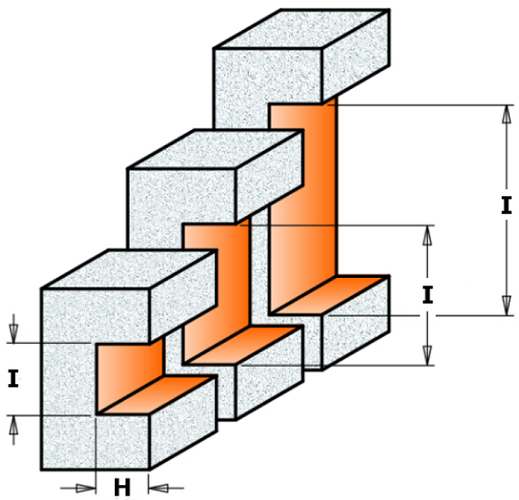

Constructional

After processing the workpiece with this tooling, a groove resembling a trapezoid (dovetail) or an inverted “T” is obtained.

This method of joining parts is considered one of the most reliable, since the spikes move into the grooves of the same shape and cannot be separated by another method.

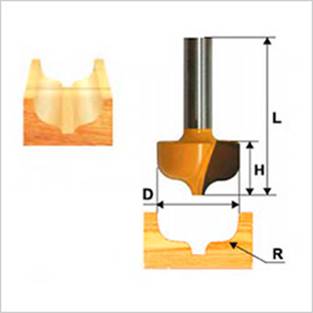

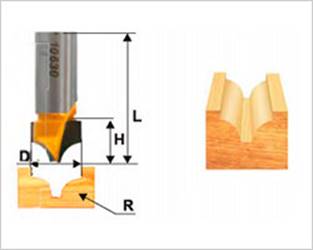

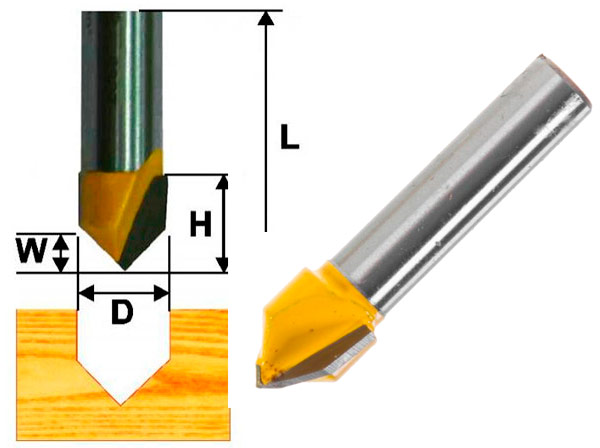

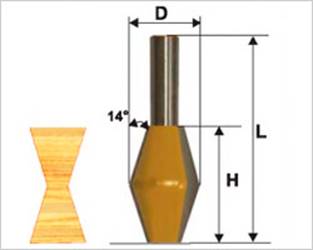

Fillet V-shaped

Despite the fact that the word “fillet” refers to any semicircular groove or groove, V-shaped cutters also fall into this category. The tool allows you to choose not only vertical grooves, but also grooves at a certain angle. Also fillet milling cutter is often used for decorative carving and changing the geometry of edges in furniture production.

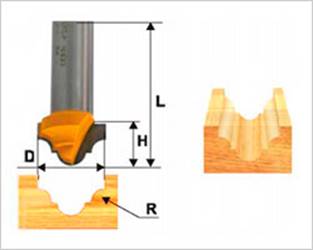

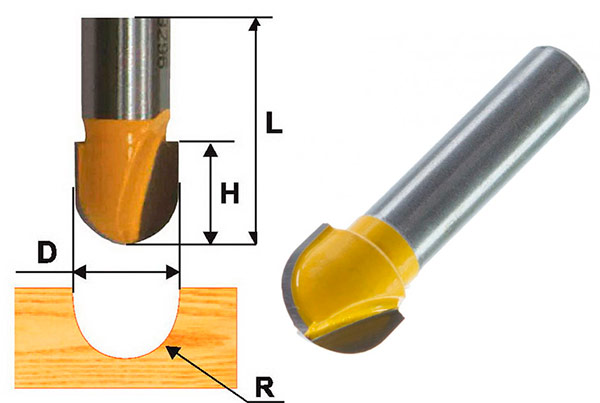

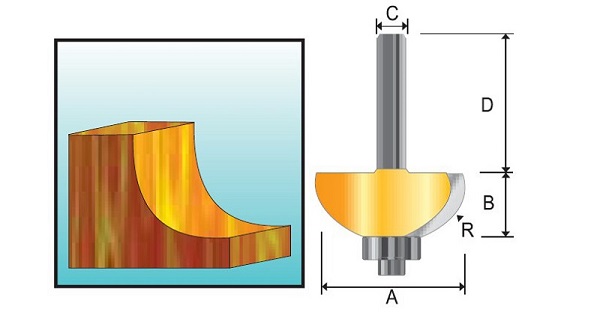

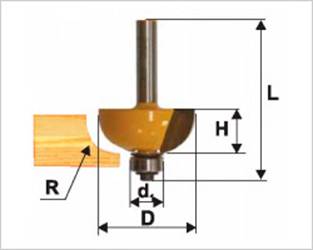

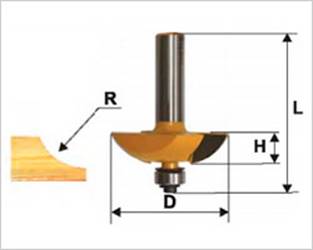

Fillet

They have a rounded cutting part. If you look at the groove after its passage in the section, it will remind the letter “U”.

The milling cutter is used to decorate the edges and ends of wood products, create complex patterns on the surface of the blank or on various plaster notches (grooves) on the surface of the product and on its edges.

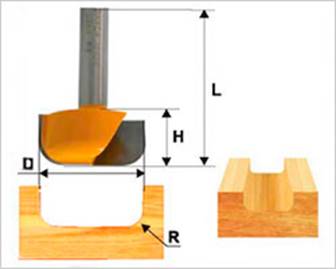

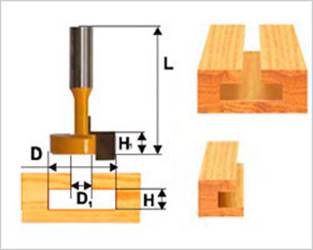

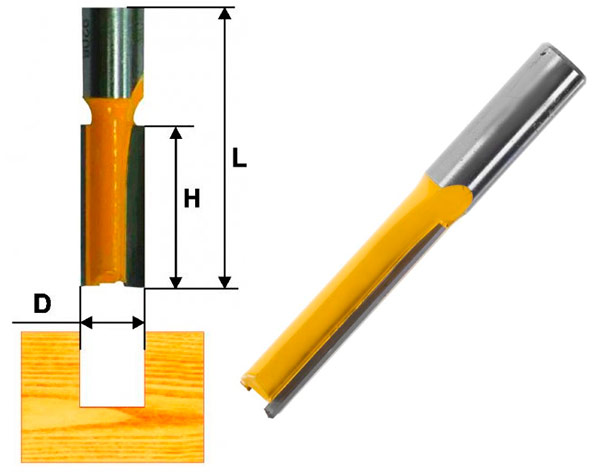

Straight lines

This is the simplest cylinder-shaped tool. The groove obtained in the workpiece has a rectangular cross section.

The equipment most often is used with submersible milling cutters.

Straight groove (finger) cutters are used if you want to choose a rectangular groove with a clean bottom, for example, for tie-in door locks and hinges.

Edging cutters

In most cases, the edge mills have thrust bearing. Thanks to him, it is possible to lead the tool on a template, processing the edges and edges of the blanks.

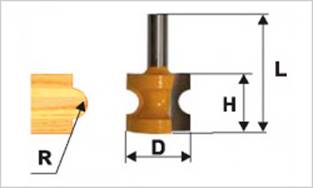

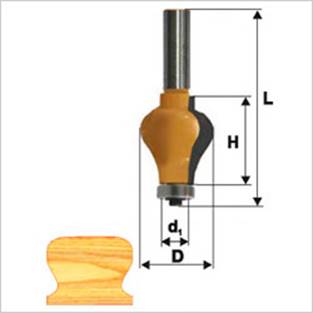

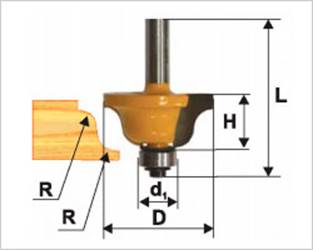

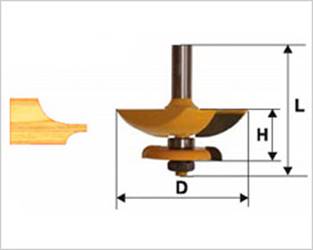

Semi-rod

The tool creates semicircular protrusions on the edges of the blanks.

If you use a half-core cutter in a pair with a molding or fillet, you can make articulated joints. Also semi-rod tool made rods of circular cross section. In this case, the workpiece is processed on both sides.

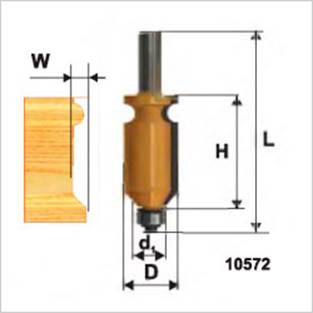

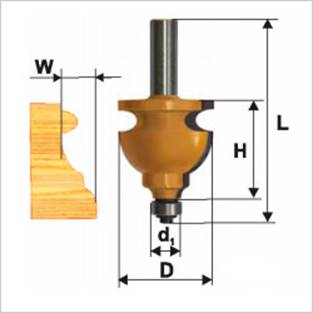

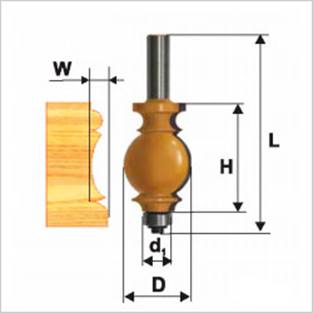

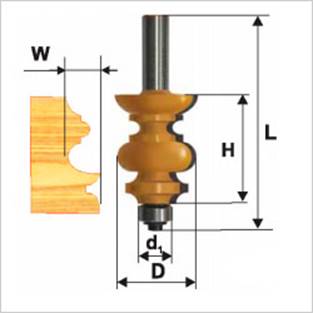

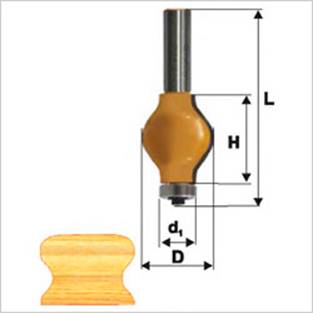

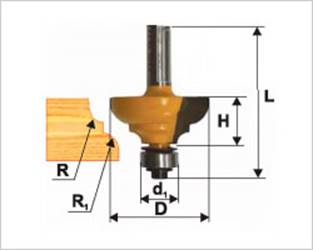

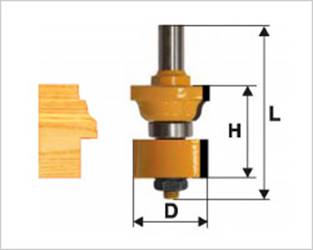

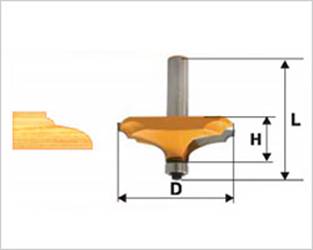

Figured

These curly cutters are also called multiprofile. Depending on the tasks, the master can use part of the equipment profile or use it in full. In the second case, you will need to install the tool in the unit, which has a capacity of at least 1600 watts.

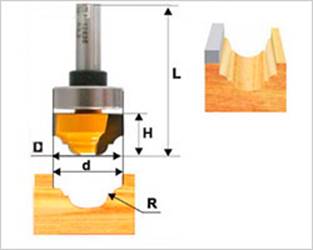

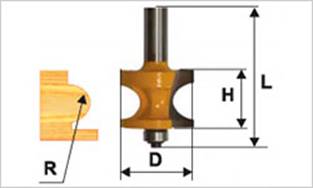

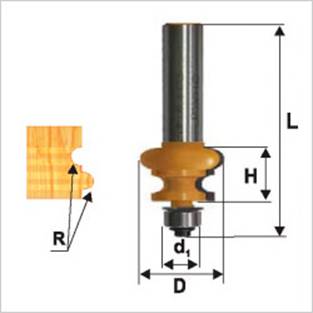

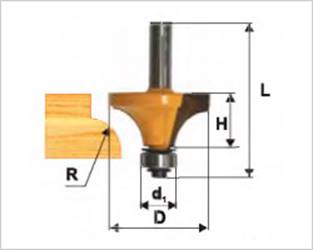

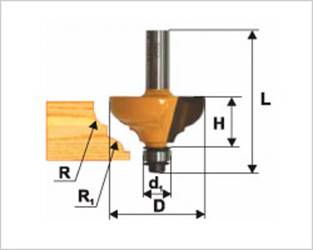

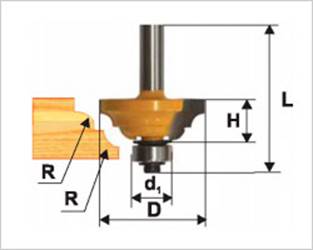

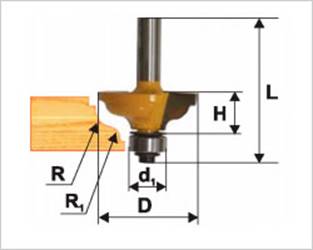

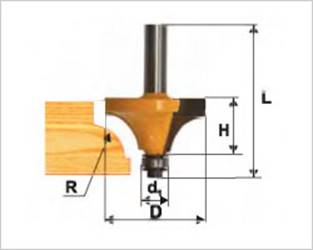

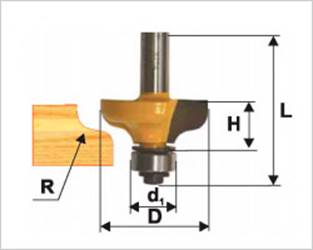

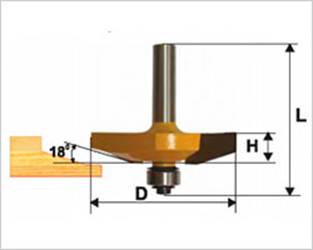

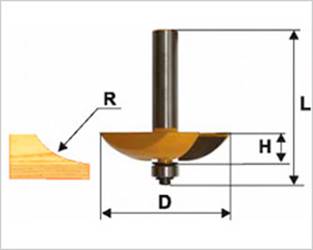

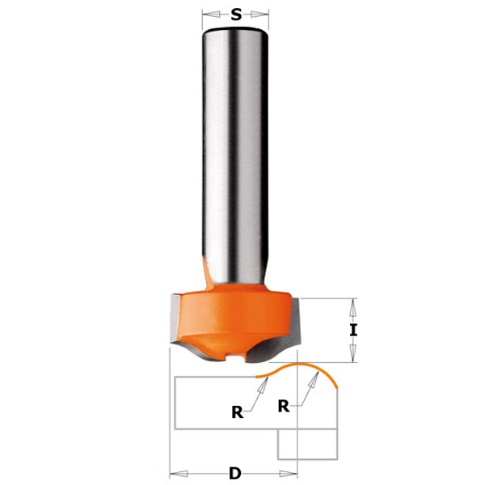

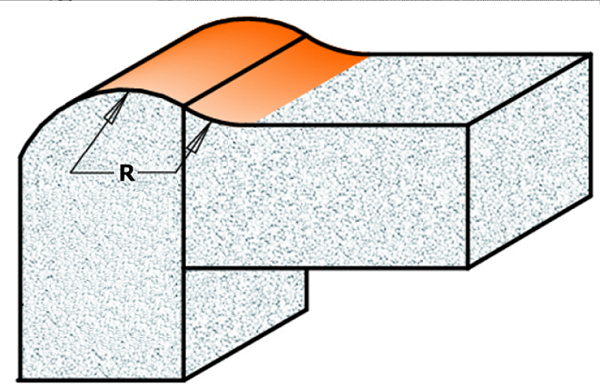

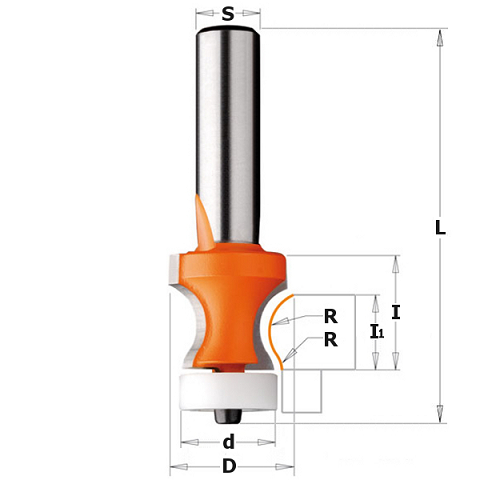

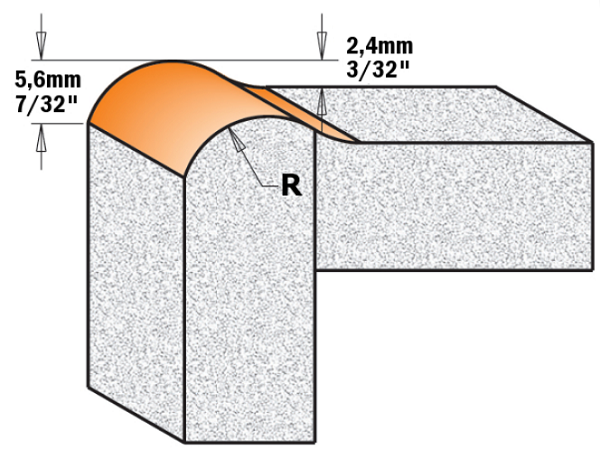

Fillet

They are intended to give the edges of the workpiece an internal radius or to select grooves with a circular cross section.

Fillet mills are equipped with one or two bearings, eliminating the skew of the tool.

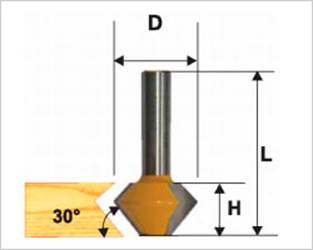

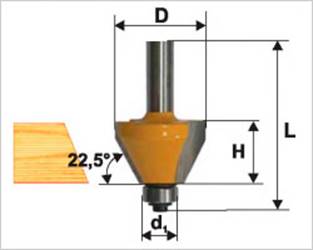

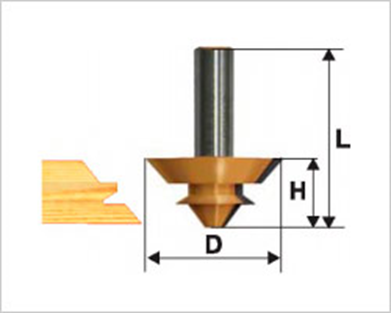

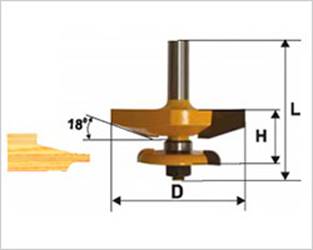

Conical

With the help of tapered cutters you can:

- chamfer on the edge of the workpiece;

- decorate the edge of the tabletop;

- create an angular cut on the edges of the workpiece before gluing them (you can get products of polygonal shape).

Also in this category can be attributed to the edge milling cutter, the angle of inclination of the blades which is 45 degrees.

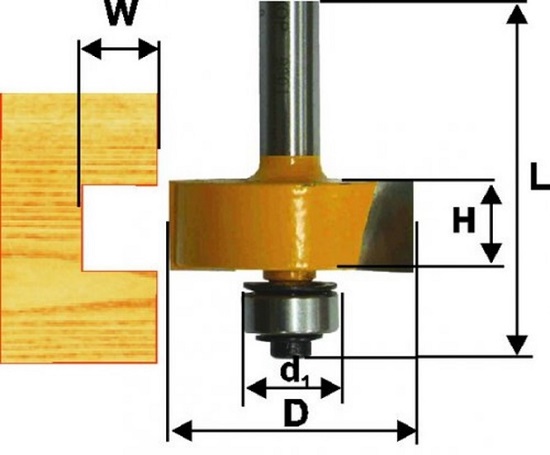

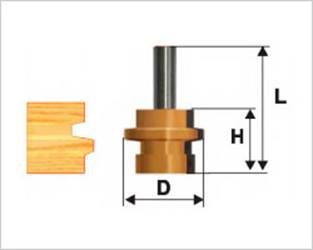

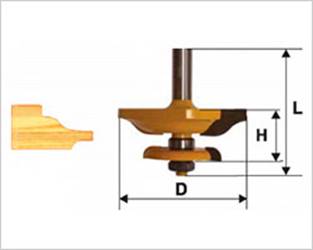

Faltsevye

Apply to quarter sampling and grooves of rectangular section. Thanks to the thrust bearing, the seam milling cutter can be used both on straight and curvilinear blanks.

To adjust the depth of the groove used thrust bearings of different diameters.

This category also applies disk mill. With its help, a groove is cut in the blank for installation of a T-shaped PVC edge.

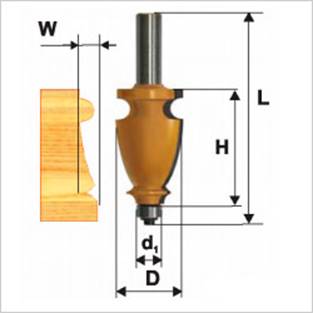

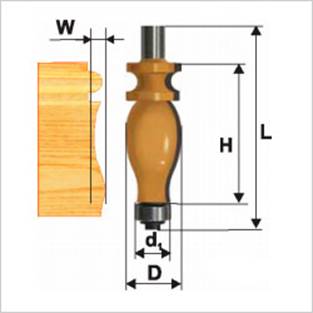

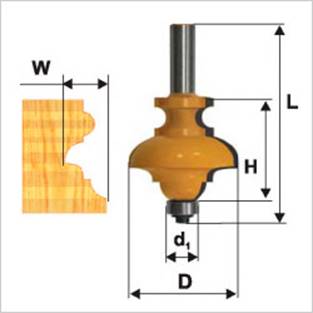

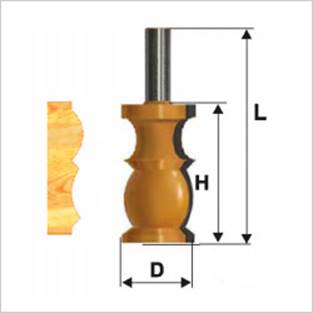

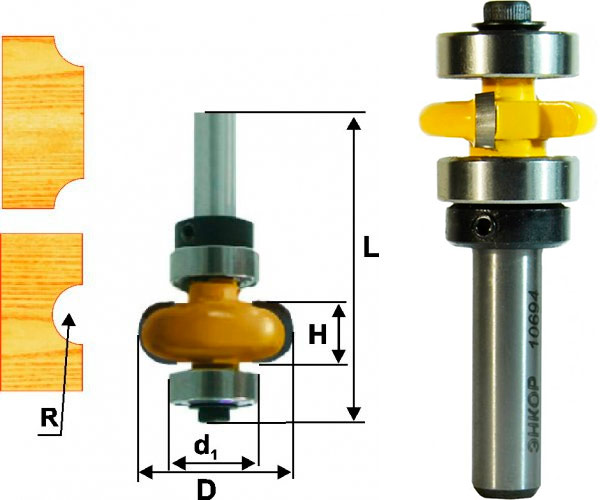

Masting

Milling cutters allow you to get arcuate, straight, as well as shaped edge on the workpiece. Working as any part of the same equipment, it is possible:

- round the edge of the part;

- get the edge with a fold;

- make semi-rod ledge;

- get hem with a sponge;

- to make decorative processing of edges, for example, making window frames.

Also, using cutting cutters, you can create ornaments of complex shape on the edges and ends of wood parts.

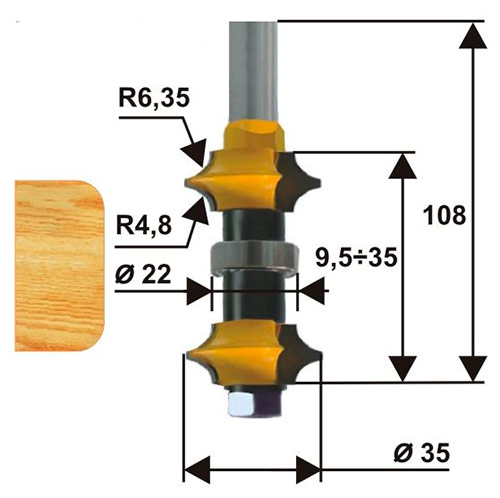

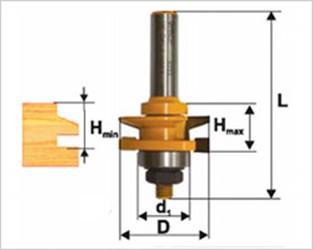

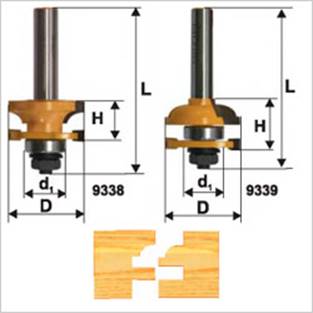

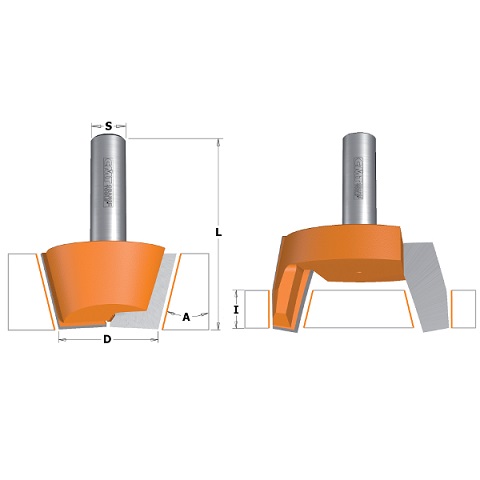

The equipment of this series can be double, as shown in the following figure.

On double cutter the distance between the elements can be changed in accordance with the thickness of the workpiece. Thanks to the two elements, the workpiece is processed in one pass, simultaneously from both sides.

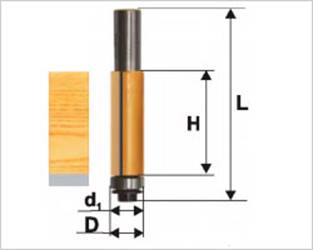

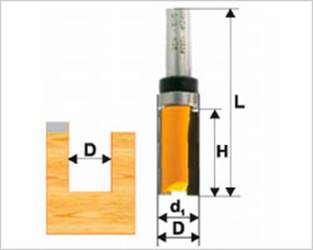

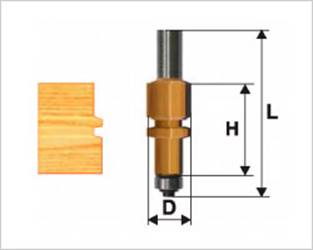

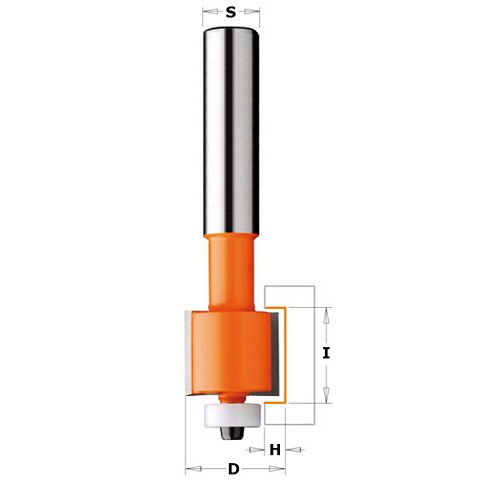

Straight lines

A straight edge (overtaking or face) cutter is used when finishing the ends of the workpiece or creating an ideal angle of 90 between the face of the part and its edge (end). The bearing can be installed at the top or bottom of the tool.

At the bottom position of the bearing, the template is fixed under the workpiece, and at the top position - above the workpiece.

In addition to the facing function, the snap-in with the upper bearing can be used as a mortise and cut a groove of a rectangular cross section on the surface of the workpiece, of course, using a template of a certain height. The diameter of the bearing is usually equal to the diameter of the tool, that is, it is flush with the cutting edge. But in some cases it is changed to a smaller or larger diameter in order to expand the possibilities of tooling.

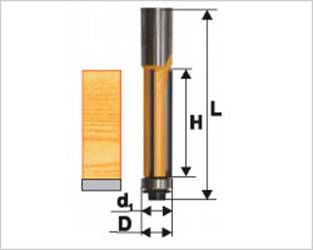

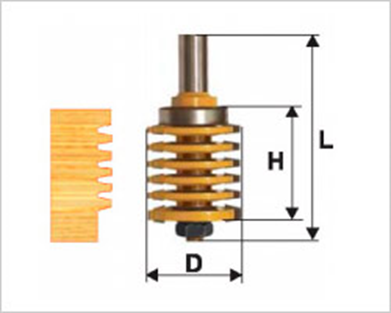

Mill "corn"

The corn cutter is also edging. Its main purpose is to grind and align the edges of the workpiece on a template. Due to the special arrangement of the knives (in a spiral) easy chip removal and the smooth course of the tool.

Combination Cutters

Splicing blanks is considered the most effective if you use a combined tooling. These types of cutters consist simultaneously of spike and groove elements: thanks to this design, the equipment will receive both profiles in one pass. As a result, the edge area intended for bonding increases, which has a positive effect on the strength of the joint.

Framework

Frame mills are integral tools.All cutting elements are installed on the base, and the master can place them in the right order. Typesetters have the following components:

- base;

- cutting elements;

- bearing;

- washer;

- locking nut.

When changing the location of the cutting elements, the shank is not removed from the collet of the unit. It is enough just to unscrew the fasteners located at the bottom of the snap-in, and all its elements are removed. Thanks folding design snap-in tool departure amount remains the same, and re-adjustment is not required.

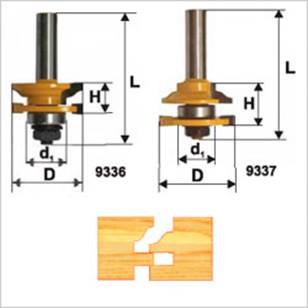

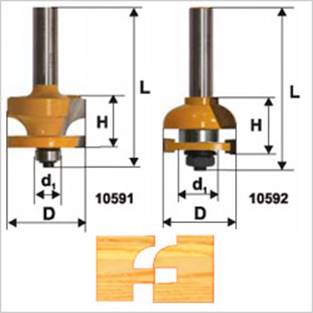

Tongue and groove

The kit contains 2 cutters, one for selecting a groove, and the other for a tenon.

Grooving spike mills have a mirror-identical profile of the cutting elements, thanks to which the machined parts are spliced as accurately as possible.

The only disadvantage of this tooling is that the grooves and spikes are made by different cutters, which have to be changed and corrected again for their outreach relative to the base of the unit.

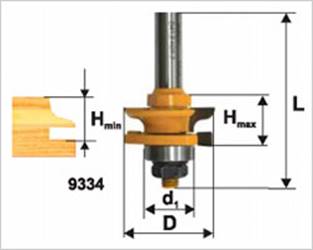

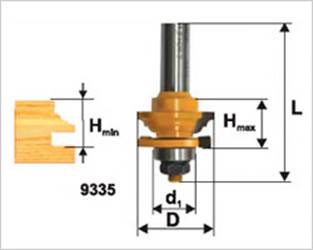

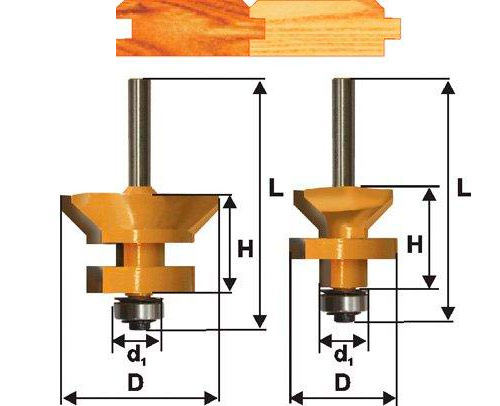

For the manufacture of lining

Cutters for the manufacture of lining in their principle of operation are similar to the groove-studded tool, but with the only difference that when connecting parts is formed V-groove between them to imitate a bar. To make a connection, a set of 2 elements is also required.

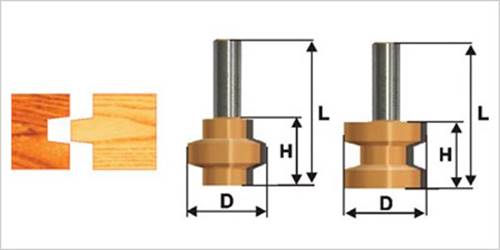

Universal

After passing the tool get 2 planes, fully compatible with each other, having a groove and spike. Both of the latter are located at an angle to each other.

For the splicing of parts, a micro-blade mill is also used.

Snap-in can be used for longitudinal splice blanks (in the manufacture of shields), and for face splicing parts.

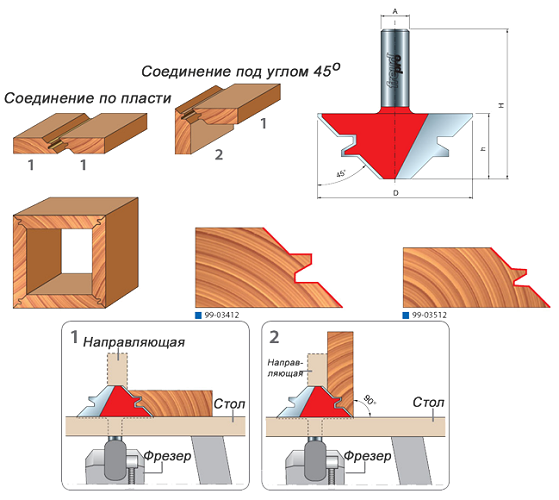

For corner splicing of wood, the equipment from the combined series is also used, which allows to prepare joints at an angle of 45 degrees.

It should be noted that for processing workpieces that need to be spliced, use the same combined cutter. The original equipment design allows you to achieve maximum quality docking parts, and also significantly saves time, because the tool does not need to be changed.

Cutter cutters

Apply a tool in the manufacture of panels, namely for decorative processing edges of parts. All equipment has a thrust bearing fixed to the bottom.The mill with the bearing can process not only rectangular preparations, but also figured. You should know that the tools for the panels have a diameter of from 50 to 70 m, therefore, in order to use them effectively, you must have an apparatus with a power of at least 1500 watts. For a household router, the treatment of the panel with this type of tooling will become an overwhelming task.

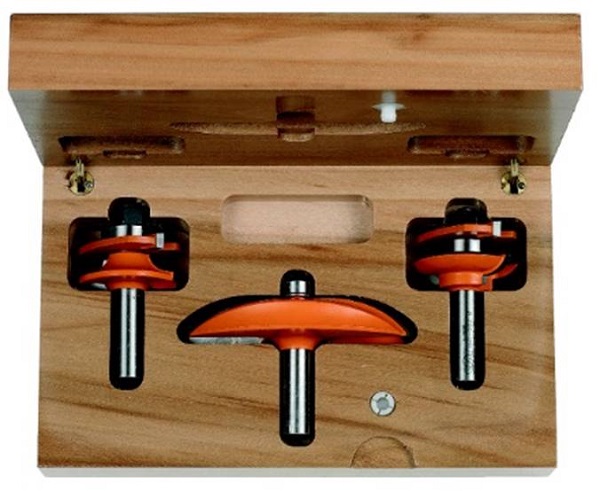

For the manufacture of doors by hand milling machine (meaning kitchen fronts) you will need to purchase a special set consisting of three elements.

The set includes the following front cutters: one paneled and two tooling for furniture piping (profile-profile).

Horizontal

Apply to pretreatment panels. To form a spike for insertion into the groove of the frame, you will need to further process the edge.

Vertical

The most common vertical cutters use for the manufacture of plinths.

Horizontal double sided

This type of tooling significantly simplifies the production process, since in a single pass of the tool a connecting spike and a part of a panel of a certain configuration appear on the edge.

In addition to the above types of equipment, many masters use and homemade cutters. Usually they are a standard locksmith drill down in a special way. How this is done at home, you can learn from video.

Criteria for the selection of cutting tools for wood

When choosing cutters for wood for a manual unit, attention should be paid to the following tooling parameters.

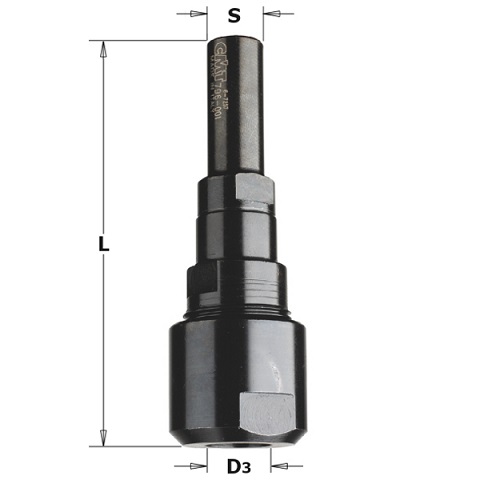

The diameter and size of the shank

It should be noted that some foreign manufacturers of cutters may indicate the diameter of the shank in inches. In most cases, if the collet clamp is installed on the unit, then there will be no problems with the installation of the tooling, of course, provided that the diameter of the collet corresponds to the diameter of the shank.

It is important to know that the collet of the hand-held unit is not a jaw chuck of a drill, into which you can clamp tools of different diameters.. The inner diameter of the collet should strictly comply with the diameter of the shank tooling. Difficulties may arise if you buy a tool with a 1 / 2ʺ shank (12.7 mm) and try to insert it into a collet with a diameter of 12 mm. At the same time, the shank with a diameter of 6 mm without problems will be clamped in the collet 1.4 ʺ (6.35 mm).

Before buying a cutter, especially expensive, read the instructions for the unit and find out which collet is installed on it.

Shank length tooling is also of great importance. Not all of it has elongated shanks, and sometimes their sizes are not enough to use the tool, for example, when extending deep grooves. Also, long tool shanks may be needed when fixing the unit under the table. In this case, it is customary to use cutter extensionwhich is clamped in the collet of the unit.

Blade Material

This is an important criterion when choosing a snap. The product can be made of high-speed steel (HSS) or carbide (HM). Blades from high speed steel easily cope with soft woods of low density. But for machining hardwoods, these cutters are not suitable. In this case, they can be replaced with equipment with carbide blades.

The location of the cutting elements

The blades on the tool can be positioned vertically, that is, parallel to the axis of the shank, or at a certain angle to it. Vertically located Blades work like a planer and cut wood more than they cut it.Therefore, if the blades are a little blunt, they will leave marks on the surface they have processed, which will have to be polished.

Blades located at an angle to the tool axis, they work much cleaner and do not form chips.

Stone Cutters

To process an artificial stone with a router (manual), you can use traditional types of cutters designed for wood, but only with carbide blades. There is one nuance here: an artificial stone is a composite material that contains the smallest abrasive particles. Therefore, no matter what kind of carbide material a mill is made of, it will suffice only to process no more than 10 meters of stone. Further, dull blades They will not give the required purity, for example, of the glued surfaces, which will affect the quality of the joint.

Therefore, professionals advise to use the best cutters from well-known manufacturers such as Festool, Leuco, Titman, Leitz, Dimar. The resource of cutting tools made by these enterprises is 5-10 times higher than that of conventional carbide tools. “Branded” equipment can already be processed from 60 to 100 meters of composite.

Cutters for wood and stone have similarities in appearance and even have the same name. Some of them are very often used to perform stone operations. But there are specially designed cutters. for processing composite products.

Cutter "antiperelyl"

With this stone cutter, you can create tide bumpers on kitchen (toilet) sinks and countertops made of composite. Typically, the full formation of the side occurs in 2 passes of the tool.

There is also a modification of the “anti-cut” cutter, which has a thrust bearing.

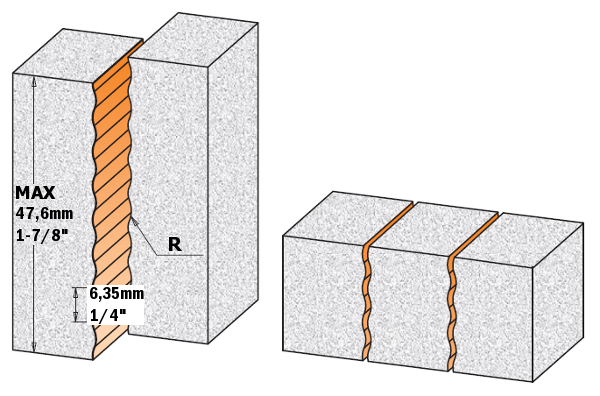

Mill "wave"

This tool is intended for surface preparation before splicing. The cutting part of the tooling has a wave-like profile.

Slotted inlay

The tooling is used to select a groove, further intended for inlay with composite materials.

Stone Repair Kit

This kit is used to repair damage to the surface of products made of artificial stone. There are 2 elements in the set. One makes a cork, and the second - a hole under it.

Also for the processing of composites can be used cutters from the company CERATIZIT.

it diamond cutterswhich are distinguished by their durability. They are made by sintering several layers of diamond chips. The multi-layer coating makes it possible to extend the tool life, because during its replacement, the new layers of abrasive appear to replace the worked layers.

Metal Cutters

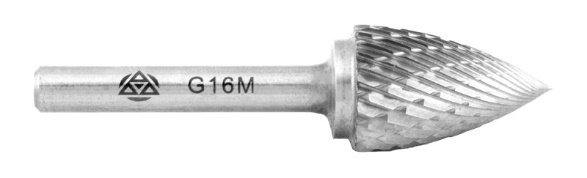

Specially created metal tooling for a manual mill does not exist. Usually masters use tooling designed for machine tools with a suitable shank diameter. Most often on manual units use end mills to create grooves. But you should know that the router is a machine that develops high speeds, which is not very suitable for end cutters. Therefore, the metal should be removed with minimal layers, a few tenths of a mm thick, and in several passes. The following photo shows a spiral cutter for metal.

Also on the router it is possible to install rotary burrs of various configurationwhich easily cope with steel, cast iron, stainless steel, brass and even titanium. But since they most often have a small shank diameter (6 mm), an adapter is required for installation in an eight-millimeter collet.

Burrs for metal are the following types.

- Disk drives. You can make all sorts of cuts and handle grooves.

- Conical (60 °). Used for countersinking holes.

- Conical with a reverse cone. The tooling is used for grinding grooves, processing sharp corners of the workpiece, removing welds in the corners of the product, processing hard-to-reach places of the holes.

- Conical with rounding. Used for machining mates, stripping welds, machining planes.

- Conical pointed. The tool can handle sharp corners, parts mates, as well as milling in hard to reach places.

- Oval. They process and expand the holes, as well as align the welds in the corners of the parts.

- Flame-shaped. Due to the universal form of the tool is used to create fillets, as well as for their processing.

- Spherical. The tooling can be used for machining holes, creating semi-circular mates and machining grooves.

- Spheroconic Sharpened. You can process the honey connected at an acute angle planes.

- Spheroconic rounded. Interconnects with internal radii are processed.

- Spherocylindrical. You can process edges, profiles, welds, radius grooves. Also, this tooling chamfers and burrs and prepare the surface for welding.

- Cylindrical with a smooth butt. Used for machining contours, welds after welding, edges, for chamfering and deburring.

- Cylindrical with teeth. Snap-in with teeth at the end is used for the same purposes as snap-in with a smooth end. Only this type of tool can work simultaneously in two planes at right angles.

Adaptations for a manual milling cutter

The main task that is performed by various devices for this unit is to expand the functionality of the device. Some of the devices come bundled with the device, but the remaining attachments to the router should be purchased separately or made by hand.

Parallel stop

This device is available in standard equipment any frezer.

Emphasis allows for straight cuts on workpieces. As the base guide is used the edge of the workpiece or the guide bus.

Guide rail

The tire serves as a guide along which the support stops. Using this device, produce straight billet milling.

Compass

This device is attached to the base of the unit and allows radial milling and cutting circles.

Slot selection

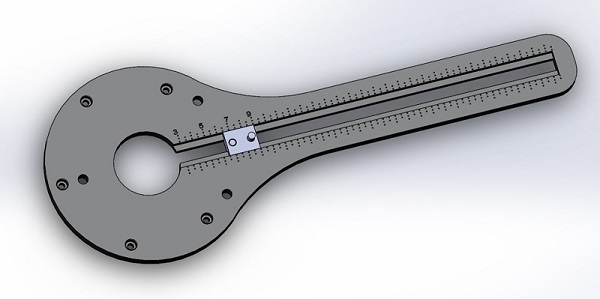

For slotting of a certain width, use the tool for the router, shown in the following figure.

The width of the groove is regulated by one platform. In this case, a straight groove cutter with upper bearing is used.

Copier

To transfer any complex ornament or pattern on the blank use special tools - copiers (pantographs).

Copier works as follows:

- the workpiece is laid under the unit installed in the pantograph;

- an ornament or pattern to be copied is placed at the right distance from the copier;

- the pointer of the pantograph is set to the initial position, after which the engine of the aggregate is turned on;

- all the movements of the pointer according to the drawing are transmitted with accuracy to the router, and it cuts a copy of the required pattern on the blank.

Copy rings and pattern

Copy sleeve is needed, first of all, to protect the template from the effects of the tool blades. In addition, the copying ring, moving along the edge of the template, transmits all of its shapes to the cutter, which processes the part under the tool.

If the hole in the template exceeds the dimensions of the sole of the apparatus, then it can be installed on a platform of suitable sizes.

Handling rotation bodies

This simple device allows cutting transverse and longitudinal grooves in cylindrical billets (turned table legs, poles, balusters).

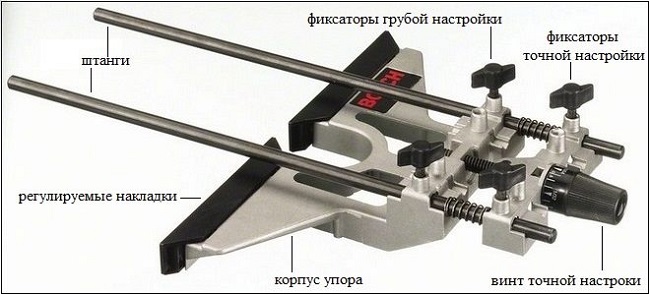

Tenoning device

To make box spikes, straight or dovetail, use a tenoning device.

Using this attachment allows you to make spikes with equal distances between them, so that the connection of parts occurs in an ideal way.

Fixture thorn groove

The spike-groove connection is the most common in the joinery business.

To make this compound, there are special tools, called pantorouterami.

Despite the apparent complexity of the design, this machine is easily made by hand according to the drawings,which is enough on the Internet.

Table for router

By setting the manual assembly to the table, you get stationary mini-machine. With its help it is convenient to handle small and long parts that can not be clamped with clamps. There are ready-made milling tables, specially designed for fastening hand-held milling machines. Below is a table produced by Corvette.

But as practice shows, most craftsmen prefer to make milling tables. do it yourselfbecause their design is not complicated. The table for a milling cutter can be made of thick plywood or from laminated chipboard with a thickness of 16 mm or more.

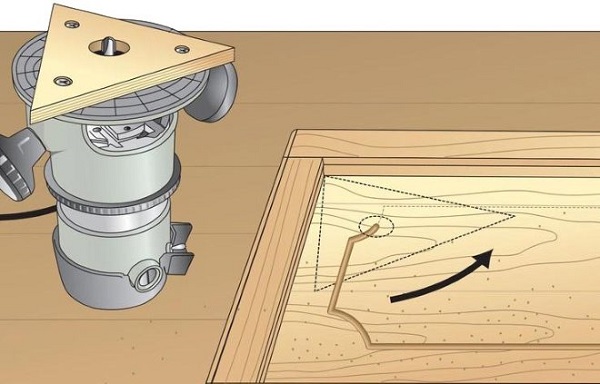

Device for the panels

If you cut an isosceles triangle, for example, from plywood, and fasten it to the bit of the router, as shown in the following figure, you will get a simple fixture for processing door panels.

This lining allows for additional decoration of already finished doors, without disassembling them, without the use of templates.

How to sharpen a mill at home

Grinding of the cutter should be carried out only after complete removal of carbon and dirt from its body and cutting elements. For these purposes, it is better to use a special cleaning fluid (shown in the figure below).

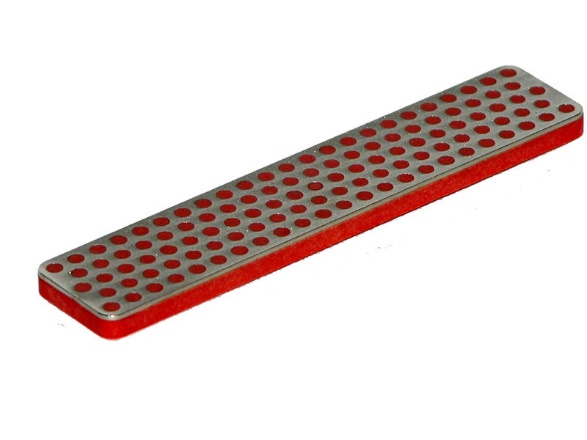

Put means on the cutting parts of equipment and wait several minutes that it dissolved a deposit. Then you should take an ordinary toothbrush and thoroughly clean the blades of any remaining dirt. After cleaning, you can proceed to the process of sharpening. To perform this operation at home, you must first purchase set of diamond barsdifferent grain.

For rough sharpening used bars with larger grain. But the process of straightening the blades must always end with polishing with the finest abrasive.

To sharpen the mill, follow these steps:

- place the bar on the edge of the table and moisten it with water. Secure the fixture if necessary;

- lay the tooling on the bar so that its cutting edge is in contact with the bar along its entire length;

- drive the sanding mill in smooth movements with equal pressure force, periodically wetting it with water;

- make the same number of movements for each blade of the tooling, so that the grinding of the edges takes place evenly.

If the equipment prepared for sharpening has a thrust bearing, it must be removed before the process begins.

Of course, if there is such an opportunity, it is better to hand over the cutter for grinding in a specialized workshopwhere it will be restored on the exact equipment. This procedure is inexpensive when compared with the cost of diamond bars.

/rating_on.png)

/rating_off.png)