Which tile cutter is better to buy

The tile is a widespread construction material for finishing works. Beautiful and proper tile installation requires workers to have the appropriate knowledge and practical skills. The process itself is associated with the need to fit the tile in size, cutting holes in it of various shapes. For these purposes, use a variety of hand tools and power tools, for example, grinder, glass cutter. But specialists who constantly perform large volumes of work use a tile cutter in their activities. In order to choose and then buy this special tool for home or professional activity, it is necessary to familiarize yourself with its kinds on the market and their main characteristics.

Content

Appointment tile cutter

A tile cutter is a special construction tool that is used to cut the following materials:

- ceramic tiles (tiles);

- ceramic granite;

- glass;

- stones;

- clinker tiles.

For paving slabs (to fit it in size) tile cutters are practically not used. In many cases it is more convenient to use the grinder.

When working with considered building materials, one often encounters various obstacles: pipes, protrusions, shoals, thresholds, curbs, and others. To lay tiles in such cases, it is necessary not only to cut pieces of the required size from it, but also to cut holes of different shapes (rectangular, round), to make a variety of bevels (due to the presence of irregularities). This allows you to achieve a quality, aesthetic result.

In general, using the tile cutter, you can perform the following work steps:

- trim tile to size;

- make rectangular or figured holes in the materials;

- create recesses;

- cut material at an angle of 45 degrees.

The entire list of the above works is able to handle only professional tile cutter, which has the appropriate design features.

Many models allow you to perform only the fit of the material in size and the creation of rectangular holes.

Depending on the type of tool used, cutting materials is performed in three different ways:

- the first is that an incision is initially made in the material on which it then breaks;

- the second way is a complete sawing;

- The third option is to bite off small pieces of material from the edges.

The method of cutting material depends on the speed of work with the equipment operated.

Advantages of a tile cutter before the Bulgarian

To determine the best way to cut a tile - tile cutter or grinder, you need to consider the pros and cons of each device.

Angle Grinder available at any construction site. When repairing this power tool allows you to perform a wide range of practical work.To cut with it ceramic or clinker tiles, porcelain tiles, stone and glass, simply install the appropriate drive, designed for sawing these materials.

Bulgarian for cutting tile

Practical accessibility and the ability to work with different types of tiles - these are the main advantages of the grinder. Also, a specialist, using it, is able not only to cut different finishing materials with high quality, but also to make holes in them of various shapes with fairly well-worked edges.

It should be noted that during the work a large amount of dust is generated. This requires the use of personal protective equipment: glasses, headgear, respirator, as well as special clothing (for example, a suit for shtrobleniya).

During the application of the angle grinder, you must be extremely careful, because this power tool, jumping out of the hands, can lead to serious injury.

Compared with the grinder tile cutter has the following advantages:

- when using manual tool models no dust;

- it can be used to cut material more smoothly and efficiently, cut off from it thin strips (up to 1 cm thick), which reduces the number of defects at the exit;

- he is much safer to use;

- if in work to use a suitable electric tile cutter according to its characteristics, then all operations can be performed faster, easier and with greater convenience.

Despite these advantages, purchasing special tile cutting equipment to be used in rare cases does not make sense for economic reasons. Therefore, craftsmen make their own hands from the Bulgarian device, like tile cutters.

Types of tile cutters

The knowledge of what kind of tile cutters allows you to choose the device with optimum performance characteristics for practical use. The tool for cutting tiles is divided into two main types:

- mechanical;

- electric.

Mechanical models by the method of action are similar to glass cutters. Most electric units resemble a circular saw, but there are also modifications that are similar to a band saw.

Mechanical tools

Work with mechanical devices is carried out by human muscle strength, they have no drive.Mechanical equipment is represented by several varieties:

- desktop;

Tile cutter table

- manual.

Desktop mechanical products consist of the following structural parts:

- the table;

- a lever designed to break the material being cut;

- carriages;

- cutting roller;

- paws presses the tile.

To perform the markup, there is in many models of products line.

Desktop models are used to cut in a straight line and cut to size glass or tile up to 1.5 cm thick. The whole process is as follows:

- material is laid on the table;

- it is carried out with a cutting roller, leaving a cut;

- lowering the handle - make breaking tiles.

Stationary products of desktop type operate with fixed to the table bolts (there are holes for them) or not at all. The latter option is only suitable when cutting thin tiles or thin glass. From the length of the table depends on the maximum size of the tile, with which you can work.

If the desktop manual equipment is equipped with a circular cutter, then it can be used to cut round holes with a diameter of 30-80 mm, for example, for electrical sockets.

Hand tools, in turn, are divided into 2 types:

- clippers;

- cutting roller.

Nippers make curved cuts in tile or glass (up to 8 mm thick), for example, under a plinth or pipe. Their use requires the skills of similar works, otherwise you can easily damage the material.

Cutting roller You can work with glass or tile up to 10 mm thick, even on weight. With this hand-made device, both straight and shaped cuts are made.

Electrical equipment

The design of electrical equipment includes the following components:

- electric motor;

- the saw head equipped with a disk;

- the table.

Electrical equipment equip diamond discs.

To prevent excessive heat in the processing of materials powerful units are produced with water cooling.

By the degree of mobility power tools are divided into the following groups:

- manual models of electric cutters;

- machine tools.

Manual models of electric cutters weigh 3-5 kg. They are much like circular saws. Their discs, protected by a casing, rotate at a speed from 11,000 to 13,000 rpm. Such a power tool is equipped with a convenient handle, adjustable cutting angle and depth of penetration.The sole soles of some models have rollers so that the machine can be easily moved along the tile surface. A number of products are additionally equipped with parallel stops, which increases the convenience of their operation.

In addition to network modifications, you can purchase standalone battery analogs, for example, RYOBI LTS180 M, Makita 4191 DWD, Makita CC 300 DWE.

Tile cutter Makita CC 300 DWE

Manual models can be run dry by connecting a dust collector or vacuum cleaner to them, or using the wet method. In the second case, the tank under the liquid is located on top. For this reason, a manual-type electric hob with water supply by gravity will be able to be operated only when working in a horizontal plane.

Desktop electric tile cutter refers to portable machinery. Tile cutting machine, working on electricity, depending on the location of the saw head and the electric motor is divided into models of these types:

- with top placement;

- with lower arrangement.

Technique with the top location of the electric motor is divided into two types:

- console, in which the saw head is fixed, and moves the table with the workpiece;

- pavement, where the engine moves together with the disk.

Top Models provide accurate and high-quality processing of materials. The circulation of the cooler is ensured by the presence of a small pump.

Tile cutter electric Scheppach FS-4700

Units that have motor bottom, usually have less weight and size, and they are cheaper than analogues with the top placement of the drive. This type of tile cutter is designed for porcelain, glass, ceramics. The working part of the disk protrudes from the table. Its cooling is due to immersion in the water in the pan under it. The workpiece is moved along the guides.

Electric tile cutter with bottom motor

Uncommon types of equipment

In addition to the above types of equipment from organizations that specialize in cutting various materials, you can find such installations:

- stone cutter;

- laser and water tile cutter.

Concrete, stone and other slabs with a thickness of 60 cm are treated with stone-cutter.

Laser tile cutter if necessary, they use complex (shaped) cutting, for example, to create mosaic from porcelain stoneware.Such a tool is able to cut thick plates. For similar purposes applies and water tile cutter. The principle of its operation lies in the hydroabrasive method of cutting materials.

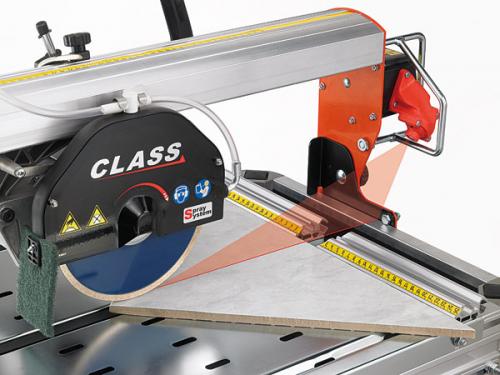

Tile cutter laser electric CLASS 110

Comparison of mechanical and electrical tools

The advantages of manual models include:

- lower cost (price of fixtures ranges from 300 to 7,000 rubles) compared with electrical analogues;

- the ability to safely perform work operations with a strong moistening of air (up to 90%);

- dust does not form when cutting materials, therefore a respirator is not needed;

- small sizes;

- no noise during operation;

- light weight (0.2-9).

Compact dimensions and low weight make it easy to store and move the mechanical device.

The disadvantage of handicrafts is limited thickness of processed materials. Also with their help it is practically impossible to cut strips with a width of 6 mm or less. With large amounts of work the whole process will be much slower than when using electric tools.

Electrical equipment is a powerful electric tool that is capable of cutting porcelain stoneware, ceramic tile, stone, glass over 1.5 cm thick. Using such devices, you can not only make accurate straight cuts, but also perform material bevels at an angle of 45 degrees. Due to the complete cutting of their blanks edges are rounded. Also, when using electrical devices, there is almost no output defect, if it was not originally owned by the material being processed. Operation of the power tool requires only a little effort. Dust is almost absent.

Of the shortcomings of the equipment are the following:

- large mass, size and price compared with mechanical devices;

- incorrect setting of the rotation of the disc can be chipped;

- the work is accompanied by noise of different sizes (its level depends on the model used);

- increased requirements for compliance with safety regulations.

The question of which is better - manual tile cutting or electric, is not entirely correct. The power tool, of course, is superior to its performance and technical capabilities. But it is advisable to use it only when large, regular amounts of work. Its operation is also limited by the level of air humidity and the presence of flammable or explosive materials near the cutting area. If there is no access to the electrical network, it is better to buy a mechanical device.

Characteristics on which choose an electric stove

Choosing an electric tile cutter is not an easy task, because the market is filled with products of different types from different brands. It is necessary to be guided by the following technical characteristics of this electric tool:

- power;

- disc diameter;

- speed;

- cutting depth.

For domestic use, it is enough to choose a tile cutter with a capacity from 750 to 1500 W with a diameter of installed disks from 80 to 150 mm. Such a power tool will allow you to make cuts 2-4 cm deep. This is quite enough to cut the tile, glass, thin stone.

The thicker material you plan to work with, the greater the power and diameter of the disks should be from the purchased unit.

To saw ceramic tiles, stone, porcelain, enough spindle speed without load about 3000 rev / min.

The product must have a quality water penetration protectionbecause often the work is done wet. It is good when there is protection against overloads (especially with indication) and accidental switching on. This makes the technique more durable, and the workflow safer.

Have machine equipment You should also take into account the dimensions of the table, which determine what tile size you can work with. It is necessary to take into account at the same time the build quality of this unit, the ease of cleaning up dirt from its surface. For models of machine tools with the upper arrangement of the electric drive, the equipment with a large tank under water is considered a laser pointer.

Tool Tips

Relatively inexpensive but good option for home use - it is to get a hand electric hob. It is desirable that he had 2 handles: this will increase control over his movement. The presence of the clamp will allow you to adjust the depth of cut. Water cooling is also an important element, contributing to a significant decrease in dust during operation.

If planned semi-professional or even professional activitythen affordable, a good option is to buy stationary electrical equipment with a lower drive position.

Work with high efficiency construction team will allow the operation of desktop portable equipment.

When choosing a stove, it is recommended, if there is such an opportunity, to check your favorite model by test cutting. If the result is of high quality, then you can buy the product. The easiest way to quickly navigate the choice is to read an overview of popular models of power tools. There will be indicated the best options for domestic and professional use. The price of products depends on the brand. Usually products for home use are calculated on the cost of up to 6000 rubles.

/rating_off.png)