Rules for working with a power cutter

Benzorez is the autonomous multipurpose equipment used when carrying out repair construction works, restoration or partial replacement of an asphalt covering or railway bed. With it, they make cutting of concrete, metal, various types of natural stone, brick, reinforced concrete structures. The principle of operation of the tool is based on the fact that the two-stroke carburetor internal combustion engine rotates the cutting disc. In contact with the cutting nozzle with the surface of the material is sawing.

Content

Preparation of the tool for work

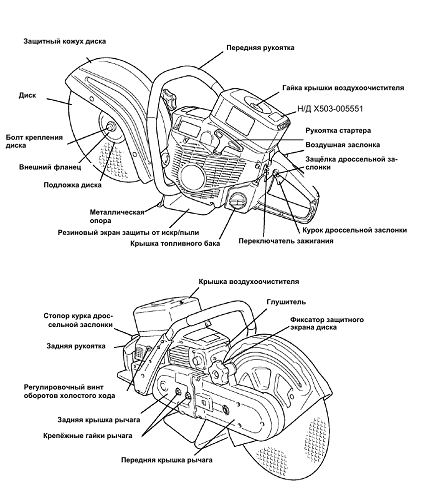

The device for a typical gasoline cutter with a disc as a cutting element is shown in the following photo.

In addition to gasoline cutters, there are chain models, which are almost identical to a chainsaw. There are also specialized modifications, such as wall chaser, rail cutter.

Pre-setting of the power tool is performed at the factory. In most cases, nothing needs to be adjusted. Preparation of all types of units for operation is performed in the same way. The actions are performed in the following sequence:

- visually inspect the technical means and cutting attachment for external damage;

- install the protective cover in the desired position, securing it securely;

- check the available switches and buttons for free travel, and the throttle lever (when you press to unlock it) for ease of rotation and return to the original position;

- install a suitable disk for work;

- check the installation of the candle - it should be screwed in until it stops;

- remove foreign objects and garbage from the workplace;

- prepare a fuel mixture consisting of gasoline and oil, stirred in a certain proportional ratio;

- check the presence of fuel in the tank of the power tool, making its refueling if necessary.

The ratio between gasoline and oil in the fuel mixture, as well as a detailed description of the safe refueling process are contained in the user manual for the product model used.

If the tool is going to work wet cutting, then in addition carry out such actions:

- connect a pipe to the connecting node of the equipment through which water will flow from the water supply system or from the tank;

- a special lever to turn on the water supply (after performing the work, its water supply is stopped).

Operated unit must not be mechanically damaged. If they are found, then you need to pre-repair the device. The used disks should not have chipping of the cutting edge, cracks and other defects. Do not use wet abrasive wheels, as well as falling from a height.

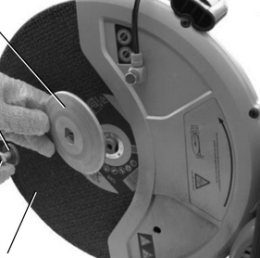

Disk change do this:

- fixed drive shaft;

- using a wrench of the required size, the fastening bolt is unwound;

- remove the bolt, washer, as well as the outer flange, leaving only the inner;

- put the disk;

- put in place all the elements in reverse order, tightly (but not excessively, without extra effort) tightening the bolt.

When installing a new drive, you need to make sure that the rotational speed for which it is designed is greater than that of the tool.. It is impossible to equip the used equipment with working nozzles if they are intended for use at lower speeds.

Starting a power cutter and troubleshooting

To start the cutter, do this:

- put the tool on a flat place, for example, on the floor;

- use the left hand to take the front grip, and with the right foot step on the back grip, pressing it against the supporting surface;

- with the right hand, for the first time, slowly pull the starter to a position of perceptible resistance, so that the cable is stretched 1/2, maximum 2/3 of its length;

- then several times pull the starter handle in a straight line with short, quick jerks until the engine starts.

During startup, you must carefully monitor the disc or chain so that they do not come into contact with the surface on which the gas powered tool rests.

It should be noted that the starter handle should not quickly bounce to the unit body, and the cable should not extend to the full stop (so as not to break).

If the model used is not equipped with an electronic system that regulates its warm and cold start in automatic mode, then you will need to carry out all operations manually.

Cold start do this:

- the air damper is pulled out to the full stop;

- Ignition is installed in the working position;

- blocking, holding the lock button, the throttle;

- pressing the trigger of this flap, hold it down;

- starter motor start;

- regulate using the trigger throttle (pre-unblocking it) engine speed during operation.

Cutting materials is not recommended with a fully open damper. It should be partially covered. Warm motor (not yet cooled after work) it is recommended to start, without using for this purpose the air damper. If it does not work, then you will need to use it, as in a cold start.

It happens that the engine in general does not start or its start passes with considerable difficulties. Possible causes of problems and ways to eliminate them are presented in the table below.

| Causes of failure | Remedy |

| ignition switch not turned on | it is necessary to switch it to the working position |

| the fuel mixture has run out or is of poor quality or water has entered | you should fill in with new fuel, pouring out the old one (if it was) |

| fuel filter clogging | it is required to replace it with a clean one and flush the fuel supply hoses and the tank |

| Spark plug failed or dirty | you need to put a new one or clean the old one by adjusting the distance between the electrodes |

| magneto malfunction either wiring | It is recommended to contact the service center |

| motor is full of fuel | you must manually scroll the engine, with the candle unscrewed at the same time, which will need to be dried |

| clogged air filter | You can try to clean it or put a new one. |

| out of adjustment carburetor | need to configure it again |

| insufficient air is supplied to the engine | need to adjust the valve |

After starting, the motor must be given some time to work, so that its operating temperature is reached.

Rules for cutting materials

Concrete and metal, as well as their connection (reinforced concrete structures) are the main materials that most often have to be cut with a gasoline cutter.Working with a power cutter requires compliance with the following general rules.

- It is first necessary to apply marking lines on the working surface.

- Sawing is required at maximum engine speed, which should be achieved before the disc touches the material.

- The cut should be performed only on straight lines.

- Hold the tool firmly with two hands, while avoiding springy movements and rocking. It is necessary that the cutting edge of the nozzle in contact with the surface of the material smoothly.

- During the long working period it is necessary to take periodic breaks for rest, during which the equipment will also cool down.

- Do not exert excessive force on the power tool, so that its disk does not jam, there is no overload.

- During work it is necessary that the body is in a stable position.

- The depth of the cut should not immediately be maximum when sawing massive parts: you need to cut through the groove for several approaches.

- When cutting large tubes, the circular cut cannot be done straight through at once either, so that the disk does not pinch and do not throw off the power cutter.

- It is impossible to keep the unit working above your head.

- If possible, materials should be cut, securing them securely, or large workpieces should be placed so that the cutting attachment does not become pinched.

- Do not use discs for grinding.

Work with metal and concrete has its own characteristics. First of all, in the cutting process are used various cutting nozzles:

- concrete is sawn with steel discs, in which the cutting edge is coated with diamond;

- abrasive circles are used for cutting metal.

It should also be borne in mind that the working nozzles can be designed only for cutting materials using the wet or dry method, or both. The purpose of the cutting wheels is indicated on the labels pasted on their front side. Manufacturers indicate that for diamond disks the important point is the direction of rotation: if it does not coincide with that indicated on the label, the diamond plating will wear out much faster. The remaining nuances of cutting concrete and metal should be considered separately.

Work with metal

Cutting metal does not require the use of such powerful gas cutters, as when cutting concrete. Usually used power tools up to 4200 watts.

When working with metal, you should follow these recommendations.

- Hold the tool at an angle of 90 degrees to the surface of the material being cut, making a vertical cut.

- Protective cover should be tilted so that sparks fly forward (away from the worker).

- To the metal, you first need to touch the disk, rotating at medium speeds, and only after creating the guide groove to crash at the maximum.

- To achieve a smooth, even cut, the tool needs to be moved with a slow, steady motion without excessive pressure.

- Thin metal pipes, sheets, rods are allowed to cut immediately vertical cut.

- Iron corners or I-beams need to be cut in parts, especially carefully working in places of contact of structural elements at corners, because the slightest bias will cause the disk to jam, followed by tearing out the power cutter from the hands.

- If the material is under tension, the cutting is performed first from the working side, and then from the opposite side, in order to avoid pinching.

In the cutting zone, the metal becomes very hot (and sometimes it melts), so you should not touch the cutting place until it cools,otherwise, severe burns may result.

Concrete cutting

For cutting concrete designed benzorezy from 4200 watts and with a disk rotational speed of about 4700 rpm. Such characteristics are needed for high performance.

Concrete cutting is performed by two methods:

- dry;

- wet

When sawing concrete related to mineral materials, there is a lot of dust. Dry way does not assume a water supply to the place of a cut. For this reason, when working with this method, the use of safety glasses with a respirator is required. Approximately every 30 seconds it is required to take breaks in the work for the disk to cool.

Benzo tools, designed only for dry operation, are cheaper than analogs with the possibility of wet cutting, but the process of sawing concrete with it lasts much longer, accompanied by considerable dustiness. Partially reducing the amount of dust helps periodic watering of the cutting area with water. Dry sawing method is suitable only for small amounts of work.

Wet cutting method characterized in that water enters the cutting zone through pipes attached to the protective casing.It cools the disc and suppresses dust. The duration of the work process is significantly reduced due to the fact that it is not necessary to take frequent breaks. Also, the presence of a water cooling system allows you to increase the life of not only the cutting nozzle, but also the cutter itself. The wet method is used with significant amounts of work.

Getting to sawing concrete, you should consider the following.

- If the concrete structure exceeds 100 mm in thickness, then with high probability it is reinforced, and this must be taken into account when choosing a suitable disk.

- To evaluate the work of the gas cutter, it is recommended to pre-make a notch to a depth of 1 cm. This will allow you to determine the approximate amount of time it will take to work.

- Simplify the sidebar will allow the fixation of the line cut wooden block (especially with significant strength of the monolith), which after creating the groove of the desired depth will need to be removed.

Regardless of the cutting method chosen, you should follow the general rules discussed above. Also, concrete is often sawn by hand. chain cutters. They work as chainsaws.

Safety when working with a power cutter

When working with gasoline torches, the main traumatic factor is a fast-rotating disk. If you cut any material with a gas cutter, then the smallest particles get into the air, forming dust. Especially a lot of it arises when sawing concrete. Over time, if you do not take appropriate precautions, it affects health, causing various diseases of the eyes, skin, respiratory tract and lungs.

Excessive noise It affects not only hearing, but can also cause headaches and other more dangerous consequences. Power tool vibration during its operation has a negative effect on the musculoskeletal system (especially the hands).

Gasoline is a flammable substance. If handled carelessly, fuel can be a source of fire.

In order to prevent or minimize the effects of health hazards, the following rules for working with a power cutter should be observed.

- When operating the gasoline cutter, you should use personal protective equipment: a helmet, special clothes and shoes, gloves, headphones, a goggles respirator or a mask.

- It is allowed to work with gas powered tools only to adult workers who have undergone preliminary training, safety briefing, examination of a doctor who can use various fire extinguishing agents.

- The use of equipment is prohibited for persons with health problems or who are under the influence of alcohol, drugs or psychotropic substances, as well as in an inadequate mental state.

- Only a serviceable tool with intact discs that are appropriate in size and type of material to be processed is allowed to operate.

- The fuel used must correspond to the brand specified in the instructions for the model used.

- Refuel equipment should be away from possible sources of fire: in places that are safe from the point of view of a fire.

- It is allowed to carry out maintenance only of equipment not included.

- The working nozzle can be changed only if the unit is turned off;

- When cutting materials, the user should be as focused and attentive as possible.

- The power cutter should be used only for its intended purpose specified in the operating instructions for it.

- Carry the unit with a non-rotating disc.

- At the site of work, you must always have a first-aid kit with first-aid equipment.

To avoid burns, do not touch the hot parts of the power tool after use: the cutting head and the muffler.

Independence from the power source, mobility and high power, providing high performance, made gasoline cutters equipped with discs demanded by representatives of different professions (firefighters, rescuers, builders) and home craftsmen. Getting started, you must first familiarize yourself with the operating instructions attached to the model of tool used. When cutting materials should take into account their features and use the appropriate nozzles. Safety when working with a power cutter should always be in the first place.

/rating_off.png)