Accessories for circular, miter and saber saws

The saw disk is the integral element of any power saw. It is installed both on the manual cutting tools, and on the stationary equipment. There are many types of discs that differ in the shape of the cutting teeth, the angle of their sharpening, the diameter and the material from which they are made. From the right choice of equipment for a certain type of material depends on the performance of the tool, the quality of the cut, and the safety of the operator.

Content

How to choose discs for circular and miter saws

You should know that changing the type of disc on a saw, you can handle the following materials:

- soft and hard wood;

- materials based on wood (MDF, MDF, laminated chipboard, OSB, plywood, floor laminate, etc.);

- natural and artificial stone;

- non-ferrous metals;

- plastic products;

- metal products (corrugated, pipes, metal profiles, fittings, etc.).

Each cutting tool has certain characteristics that should be considered before use.

Outside diameter

The diameter of the installed cutting tool can not be larger than the inner diameter of the protective casing. In different models of units covers can have both small and large sizes. A large diameter disk will not fit under the casing with a smaller internal diameter. At the same time, you can install a small disk under a large casing, but at the same time significantly reduced safety of use of the unit.

Depth of a cut depends on external diameter of equipment. But the following pattern should be taken into account: the more the equipment is immersed in the workpiece,the greater the load falls on the motor of the apparatus.

The diameters of the discs for a hand-held circular saw can be in the range of 130-250 mm.

Landing diameter

It is very important that the diameter of the machine shaft and the disk seat match each other. Some types of sawing equipment have additional holes for rigid fixation on pins. The equipment, as a rule, has seats of the following sizes: 16, 20, 22, 30 and 32 mm.

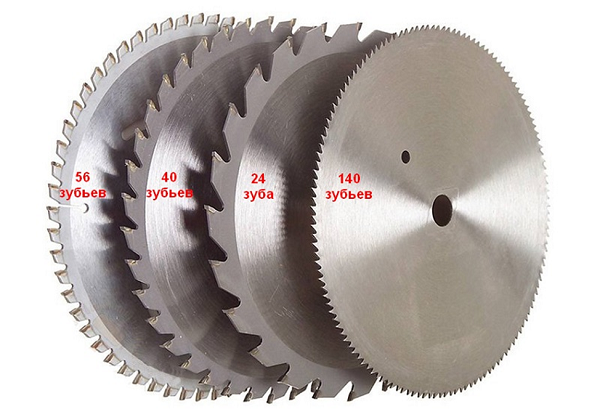

Number of teeth

This parameter affects clean material handling and performance. The fewer teeth the tooling has, the faster the piece is sawed due to better chip removal. But reducing the number of incisors leads to a decrease in the quality of the cut. Increasing the number of teeth, respectively, improves the quality of the cut. But it is worth knowing that the more teeth the tool has, the greater the load experienced by the apparatus's electric motor. Conventionally, the equipment for circular power saws is divided into 3 groups:

- from 80 and more incisors - a large number;

- from 40 to 80 incisors - the average number;

- from 10 to 40 teeth - a small amount.

For each specific task, the equipment is selected with the required number of cutting elements:

- the maximum number of teeth required for cutting wood across the fibers;

- for sawing along wood fibers it is better to use a tool with a small number of incisors (up to 60).

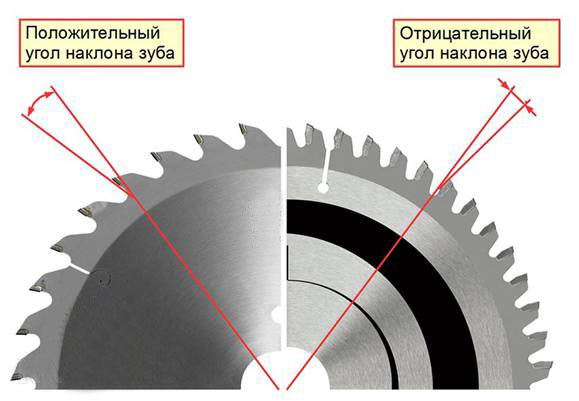

Teeth slope

Equipment for manual or stationary circulars has a difference in the angle of inclination of the teeth. It is both negative and positive with respect to the radius of the disk.

The inclination angles of the incisors can have the following values;

- angles from 5 to 15 ° are considered standard;

- angles from 15 to 20 ° are called aggressive (positive);

- angles from 0 ° to -5 ° are called normal (negative).

For miter saw It is customary to use discs with zero or negative inclination of the incisors. This is due to the fact that the working part of the tooling enters the workpiece along a different path than the circular saw mounted on the hand tool or on the machine tool. Disk with zero or negative inclination of the incisors as it presses on the workpiece from above and scratches the material. In this case, the workpiece remains stationary, resting on the limiter, which does not allow the disc to push it away.

If you install a similar disk on a circular, then it will be quite difficult to make a longitudinal cut. The saw will start to push away the workpiece, the cutting elements will be clogged with sawdust, and an overload of the engine of the unit will occur.

It is especially dangerous to install a tool with a negative inclination of the incisors on the hand-held circular saws, since due to the reverse impact it will be difficult to hold the tool in your hands.

For circular power saws it is wiser to use a snap with a positive angle of inclination of the teeth. Cutters in this case, being at a certain angle to the surface of the workpiece, will crash into it like a plane, pulling the workpiece under them.

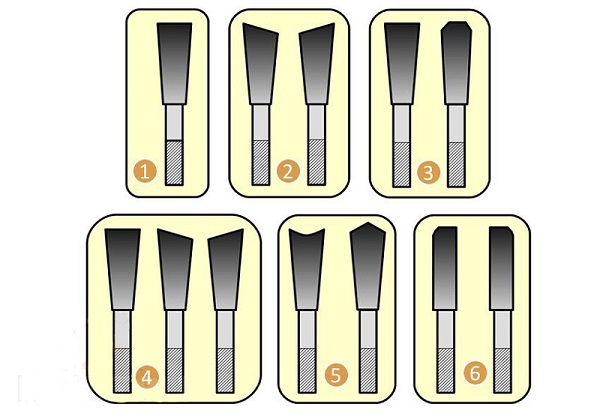

Cutter configuration

The purpose of a disc can be found on the basis of the configuration of the incisors.

- Straight sharpened teeth allow you to cut wood quickly, but at the same time dirty.

- Teeth that have an alternate bevel in different directions, allow you to cut wood in different directions, but can not stand the shock loads.

- The combination of trapezoid and flat teeth allows avoid chipping on the upper layers of the material, for example, when cutting chipboard and plastic.

- The combination of teeth with three types of sharpening increases the cutting speed and provides good clean edges when sawing both soft and hard materials.

- The alternation of triangular teeth and teeth with a concave cutting edge allows you to cutlaminate without pre-knurling.

- Serrated chamfers with wide backs can withstand hitting cement and nails on the cutting line.

Cutting metal disc for a circular saw, it has a slightly different tooth configuration.

Due to this geometry of the incisors and the material from which they are made (ceramic metal soldering), the tool productivity is increased, the vibration is reduced, and the process of metal cutting occurs without sparks.

Disc thickness

The thickness of the snap depends kerf width. The standard thickness of the saw blade is 3.2 mm. It is important to take it into account in the manufacture of furniture, for example, when a sheet cutting sheet is drawn up. In addition, it depends on the thickness of the disk strength. Thin tooling quickly overheats during heavy operating conditions. The equipment of big thickness differs in durability, but processes a large amount of material into shavings.

Disc type

Saw disks happen monolithic and hard-alloy. In the manufacture solid discs A plate of solid metal is used, the material for which is high-carbon or high-speed steel.These discs are well suited for sawing polymers and wood. The advantages of monolithic disks include the following:

- low cost;

- ease of sharpening the cutters (can be sharpened independently, without the use of sophisticated equipment);

- the possibility of multiple sharpening, thereby increasing the service life of the tool.

Material canvases for carbide discs serves as tool steel. But the tooling teeth themselves are reinforced by soldering from a hard-alloy material. This solution gives the cutting tool a number of advantages:

- clean cut;

- do not need a tooth spacing;

- cutting of hard materials is possible;

- after grinding, the incisors have a longer service life than high-speed steel teeth;

- high cutting speed;

- reliability in work;

- a wide range that allows you to flexibly select equipment for different types of work.

But carbide discs have disadvantages. It may be noted the high cost and the fact that sharpening is done only on special machines.

Disc construction

When choosing accessories for circular saws, one should take into account the quality of the product, which you can learn about by carefully examining the disk. Good saw blades for wood are laser cut from sheet steel, and then carefully balanced and polished. Signs of the operations performed on the disk can be seen if you look at its surface in the light. There will be visible radial marks left by the grinding machine, which diverge throughout the fabric, starting from the mounting hole. Budget saws do not have such marks, which indicates the absence of balancing.

Also deserves attention and grinding quality. The body of the disk should not be rough, but have a smooth surface. On the poorly polished snap-in will stick the resin contained in the wood, and impede the process of sawing.

To compensate for the expansion of the metal when heated, as well as to reduce noise and quench the vibration of the disk, on its plane are made radial slits.

On more expensive equipment with the help of the laser thin spiral slots, and a protective layer is applied to the surface of the disk.

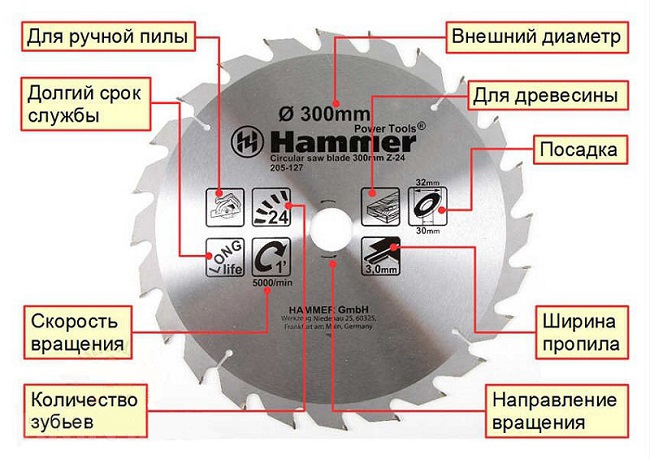

The quality disk for the circular saw is not marked with paint, all the inscriptions on its surface are applied laser engraver. From the labeling you can learn a lot of information.Which one is shown in the following figure.

How to sharpen a disk with your own hands

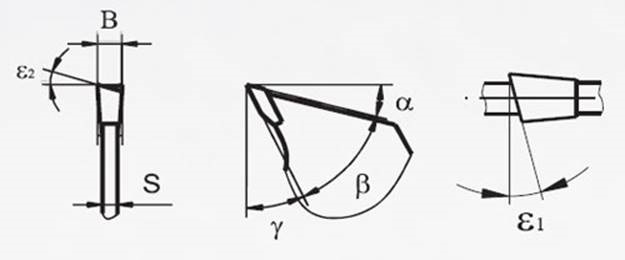

To sharpen a circular saw, four basic angles are taken into account:

- α is the back angle;

- γ is the rake angle;

- β is the angle of taper, given by the rear and front angles (β = 90 ° -γ-α);

- Ɛ1 and Ɛ2 are the bevel angles of both the front and rear planes.

The sharpening angle of the tool is selected according to the type of material to be processed and in the direction of the cut, which is very important when cutting wood. To cut along wood fibers, the tooling must have teeth with a sufficiently large rake angle (from 15 ° to 25 °). For cutting across fibers, a rake angle (γ) from 5 ° to 10 ° is required. On universal saws that allow you to cut both along the grain of wood and across, the rake angle of the cutter has an average value equal to 15 °.

The negative value of the front angle is used for tools that will have to cut plastic, non-ferrous metals and face the wooden blanks.

In addition, the angle of sharpening is affected by material hardness. The taper of the tooth (β) must be reduced before cutting hard materials.

Sharpening rules

Most often, carbide soldering wears along its upper edge. Over time, it is ground off and rounded off by approximately 0.1-0.3 mm. The front face of the incisor also wears out. Strong blunting of the cutting elements should not be allowed, since in order to align the edges, it is necessary to grind more material from the tool. The fact that the tooling is time to sharpen can be determined by the type of edges of the incisors and by the quality of the cut: there are torn edges with a large number of chips.

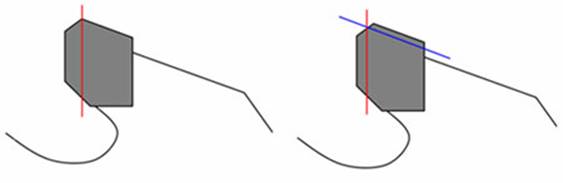

With proper holding of grinding measures, it becomes possible to sharpen the cutters about 25-30 times. This will ensure the required sharpness of the cutting edge. To achieve such results and significantly extend the service life of equipment, it is recommended to sharpen the tooth along the back and front planes. Of course, you can grind and one plane of the saw tooth, but the number of attempts at the same time decreases by 2 times. The figure below shows how the grinding of a tooth along one and both planes affects the amount of sharpening.

When sharpening the incisors, it is recommended to do the last pass with an abrasive on the back plane of the tooth.On average, the amount of grinding the metal of the tooth should be in the range of 0.05-0.15 mm.

Before starting the sharpening procedure, it is necessary to remove all dirt from the saw blade and find out the values of the sharpening angles, which are usually indicated on the tooling.

Sharpening disc at home

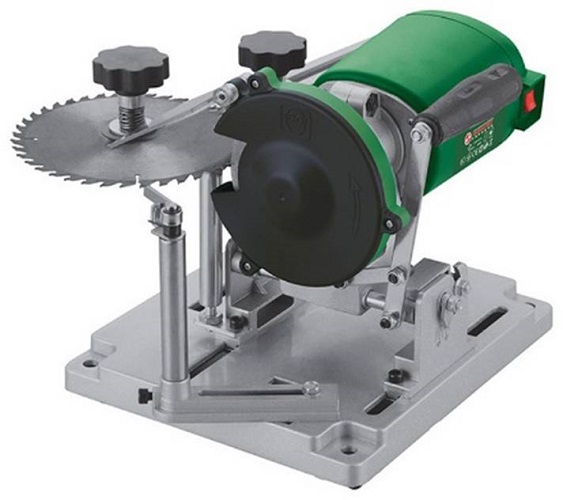

Saw discs are usually sharpened on a special machine. Buying a similar machine for the house does not make sense if you are not going to open a tool sharpening business for circular saws.

But how to sharpen a circular saw without professional equipment? To sharpen the saw blade with your own hands, you will need the presence of:

- the grinding desktop machine (it is possible to adapt the Bulgarian for these purposes);

- abrasive wheel (better if it is a diamond dish for sharpening);

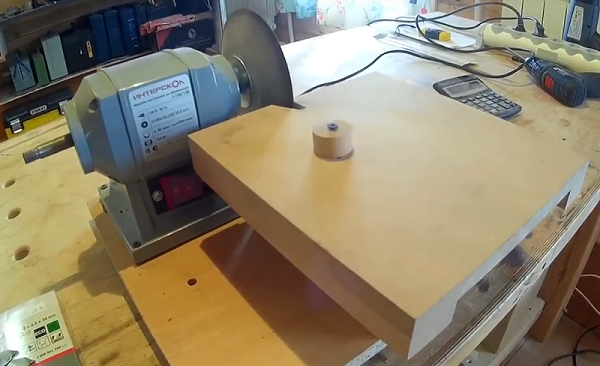

- simple fixture that can be made from chipboard scraps.

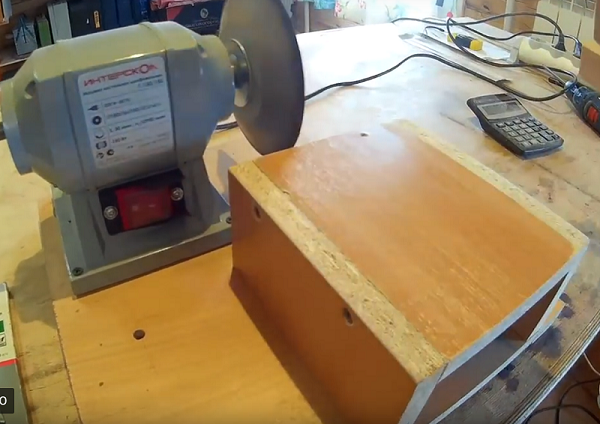

The last device is a table consisting of a moving upper carriage and a fixed base. The following photo shows the base without the carriage.

In order for the carriage to move correctly, in the horizontal plane, along its edges, you can fasten the slats or install it on furniture telescopic rails.Further, in a certain place of the carriage (experimentally) a washer is installed with a diameter corresponding to the fitting hole of the tooling.

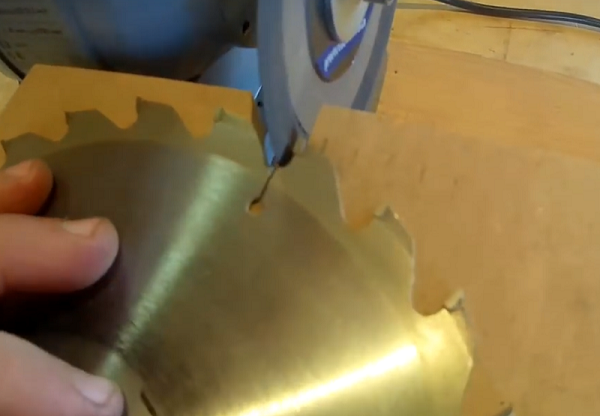

The saw disk is put on this washer and together with the carriage moves to the diamond circle.

For even sharpening, it is possible between two teeth (left and right of the grinding wheel) to be screwed in using a self-tapping screw, which will serve both as a stop and as a stop.

After the first cutter is edited (it is recommended to mark with a marker), the carriage moves away from the diamond wheel, the disk is moved by one tooth along the stops, and the sharpening of the circular saw continues.

If you want to grind off the teeth at an angle, then you can put a thin strip of appropriate thickness under the table on one side and sharpen it through one tooth. Further, the plank is enclosed under the other side of the table, and the operation is repeated on not stocked cutters.

Types of saber saw blades

The cutting tool of a saber saw is a blade, which is a plate made of special high-strength alloys, which has cutting teeth on one side. With the help of different types of cloths, you can make cuts without chipping and burrs with maximum precision.

The shape of the teeth

The shape and size of the teeth of the blade depends on the cleanness of the cut and the cutting speed. Also for the processing of certain types of materials developed a special form of cutters. So, saber saw blades can have the following tooth shapes.

- M-shaped teeth. The canvas has milled cutters, which allow to cut material both on the forward and reverse course. The rigging is used for cutting ferrous and non-ferrous metals, stainless steel, and wood, especially if it contains metal particles, as well as various types of plastics.

- Sharp, milled, variable pitch teeth. The blade has divorced cutters and is used for direct cutting of all types of wood, including those with metal particles.

- Corrugated milling cutters. The equipment is used for cutting metal up to 2.5 mm and any wood species with metallic inclusions.

- M-shaped, inclined, with variable pitch. This is a versatile and high-performance equipment with divorced teeth. Designed for cutting all types of wood with metal inclusions and for cutting metal up to 2.5 mm.

- Small, milled, divorced cutters. The canvas is used for direct cutting of metal products with a thickness of not more than 1.5 mm.

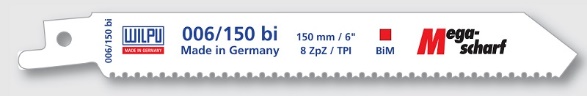

In addition, the paintings differ in the material from which they are made, as evidenced by the markings applied on any type of equipment.

Marking of canvases

Saber saw blades are made of the following materials.

- HCS. This marking indicates that the basis of the tool is high carbon steel. Saws are designed for cutting wood and products based on it, as well as plastic and rubber.

- HSS - it is tool high-speed steel. With it, you can work on non-ferrous metals, as well as cut sheet and profile metal.

- Bim - It is a bimetallic alloy, which is a combination of strong and flexible steel HSS and HCS. These blades have a long service life and are used for cutting aerated concrete, as well as sawing boards with nails.

- HM / CT - this is a carbide tooling. Saws are used for cutting porous and abrasive materials: structures made of concrete, fiberglass and fiberglass, aerated concrete and tiles.

- CV - This is a chrome-vanadium alloy. The equipment made of it is characterized by high wear resistance and is used for plastics and wood of any species.

Criterias of choice

When choosing a canvas for a saber-type unit, it is necessary first of all to pay attention to tool shank. Fastenings of cloths can be both universal, suitable for the majority of models of units, and intended only for one brand of saber saws.

Also of great importance tooth size. Large teeth give a high cutting speed, but can not provide good quality cutting. Therefore, to get a neat cut, use a tool with a small tooth.

Cutters of saber-type cloths can be ground or milled. Snap, having polished cutters, used for cutting soft materials. To cope with metal or hardwood, use saws with milled cutters.

Cloths with divorced teeth are characterized by high productivity, while tooling with wavy incisors processes the part more qualitatively.

/rating_off.png)