Homemade devices for grinders

The possibilities of the grinder can be expanded not only at the expense of various attachments, but also by installing it on special home-made devices. As a result, a cutting machine can be obtained, with which it is possible to accurately cut metal blanks at any angle. In addition, the grinder can be installed on the carriage, and use the resulting machine for cutting sheet steel.

Content

The cutting machine from the grinder

In order to understand how to make a cutting machine from an angle grinder (LBM), you can look at the various drawings on the Internet. But they will not help much, because all the dimensions of the parts will still have to be selected, based on the dimensions of the grinders you have.Options for the implementation of devices can be both simple and more complex, requiring the ability to handle the welding machine.

Option 1

To make this fit for the grinder, you will need welder skills. So, you need to do the following.

First, cut off from the corner (50x50 mm) 2 small pieces. Their size is selected on the basis of the dimensions of the gear unit of your angle grinder.

Next, drill holes in them with a diameter of 14 mm and screw the corners to the angle grinder, as shown in the following photo. If you do not have suitable bolts, you can use M14 threaded rods. Just be careful that the bolts are not too long. Otherwise, in some models of angle grinders, they can cling to the impeller located in the gearbox housing.

Without removing the corners from the grinder, grab them by welding. After that, the corners can be removed and well scalded.

Grind the weld seams with a grinder nozzle for the grinder.

Then you need to make rotating arm supporton which the machine will be attached. To do this, pick up 2 pipes of such diameters so that one could enter the other without much effort.

For a more accurate cut on the tubes, you can glue the masking tape and draw a line on it.

Then, turning the tube, carefully cut it with the angle grinder.A segment of a smaller pipe diameter should be shorter by 20 mm (thickness of 2 bearings) - it will serve as a spacer.

Pick up for a thicker pipe 2 suitable for its inner diameter of the bearing. After that, insert a thin tube into a thick one and press the bearings on both sides.

Then insert the pin into the bearings. Before the nut, be sure to lay the washer.

When the turning mechanism is ready, you need to weld a small piece of the corner to it.

The next step is done pivot stand from the same corner 50x50 mm. To make the segments of the same length, the corners can be tightened with a clamp and cut.

Also, without unwinding the clamp, they can immediately and drill.

Attach the corners with the drilled holes to the ready-made rotary unit with nuts.

To this rack, weld the corner more authentic, as shown in the following photos.

Now you need to decide on lever lengthon which LBM will be attached. This is done by the method of selection, based on the dimensions of your Bulgarian. It is possible to lay out the details on the table and calculate the approximate dimensions of the lever, which is best made from 2 segments of a square shaped tube 20x20 mm.

The pipes must also be clamped and cut to the same size.

After all the parts are ready, they can be welded together, as shown in the following photos.

At the next stage, you can attach to the finished design of the LBM and once again check what came out of it.

The ready pendulum mechanism for the grinder is easily installed on any flat surface, for example, on the workbench. Also, this design can be installed on a specially made table for it. For a more rigid mounting mechanism, you can weld small segments of the corners on both sides of a long corner, and drill holes in them.

In the following photos you can see how the finished fixture for angle grinders is fixed on the table (in this case, the metal frame is used).

It is very important to set a right angle between the plane of the cutting disc and the plane of the table. Put a square on the table and move it to the abrasive wheel installed on the angle grinder. If you initially managed to weld the fixture so that the angle between the planes was 90 degrees, then this is good. If you notice a deviation from a right angle in one direction or another, then you can correct the situation with a scrap or a long profile pipe, for example, 60x20 mm.

So that the part does not move when cutting, a corner can be fastened to the table, which will serve as a stop. Also, for accurate cutting, the table can be easily improved with a simple vice made of a nut of the length of a stud that has been welded to it and a stud screwed into it.

Next you need make a protective cover. It is done taking into account the maximum diameter of the cutting disc, which is permissible to put on a specific model of an angle grinder. To make it easier to determine the size of the casing and places for its attachment, you can first make a template, for example, from a piece of cardboard.

- From tin required to cut 2 blanks for the future of the casing.

- Screw an aluminum corner to one of the blanks. With it, the cover will be attached to the rod fixture.

- Twist the two halves together.

- Drill holes in the pendulum rod for the angle bracket attached to the casing, cut the threads in them and fasten the protective cover.

In this case, the casing will also serve as a limiter for the cutting tool, preventing it from going too deep into the table during the machining of the part.

It would not be superfluous if for a lever with a grinder attached to it make springing. In this case, make it simple: insert a smaller tube on the back of the bar and attach a spring to it, as shown in the following photo.

In this case, the manufacture of a cutting machine with your own hands, in which an angle grinder is used as a drive, can be considered complete.

Option 2

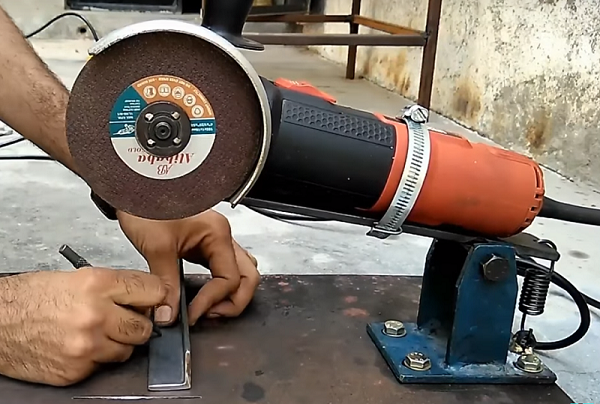

The next version of the device for the grinder, with which it will be possible to cut metal blanks, is done as follows.

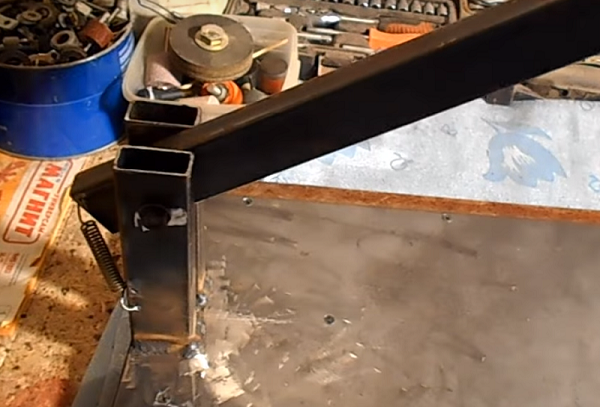

- Take 2 pieces of profile pipe of the same height and weld them to the rectangle previously cut out of sheet metal.

- Drill in 2 racks and in the lever (the length is chosen experimentally) holes, then fix the last with a bolt, as shown in the photo below.

- Attach a spring to the rear of the lever.

- Drill a through hole in the intended place of mounting the angle grinder on the rod.

- Now you can fix the grinder on the table.

Thus, it turned out a simple cutting machine. To impart additional rigidity to the attachment of the device to the lever, you can use clamps, previously laying between the casing of the angle grinder and the pipe, for example,wooden bar.

For accurate cutting, so that the workpiece does not move, you will need to fasten a corner to the table.

For a little grinder a similar variant of the fixture will also work, only the angle grinder will be mounted on a metal strip: on one side it will bolt on the angle grinder itself, and on the other side with a clamp.

For powerful angle grinders adjusting is done on the same principle, but from larger profiles than in the figures above.

It is not necessary to use dumbbells as a counterweight. It is enough to find a suitable spring.

Option 3

This adaptation option is the simplest for making your own hands. It is made without the traditional stand (rack) for the rotary unit. You will need only one door canopy, a metal strip and an elastic band (you can use a rubber band from a manual expander).

The design is done as follows:

- On the one side, in the metal strip, drill holes for the canopy, and on the other, for the bolt with which the strip will be fixed to the grinder;

- screw the grinder and canopy to the strip;

- screw the canopy to the table;

- secure one end of the elastic to the edge of the table, and the other to the holder (handle) of the angle grinder.

In just a few minutes you will receive a high-quality cutting machine. This device is also mobile, because it can be carried with you in a suitcase with tools, and, if necessary, mounted on any flat surface.

When installing this device, do not forget to fix a corner on the table to rest the workpiece into it.

Cutting sheet hoists with angle grinder

For cutting sheet metal will need to purchase special carriage, which moves along the guide (square shaped tube).

But as practice shows, the cost of a good carriage is high (more than $ 100), so you can make it yourself. Since this process is rather complicated to describe, it is possible to understand the manufacturing technology of this slider. video. With the help of the device, it is possible to cut not only steel, but also ceramic tiles and porcelain stoneware.

It should be noted that when cutting ceramics a lot of dust is formed. Therefore, it is recommended to adapt the dust collector with a pipe to a vacuum cleaner to the casing of the grinder.

How to make a homemade dust collector

The simplest dust collector for angle grinders can be made from a plastic bottle of motor oil.

The nozzle is made as follows.

- Attach a disk of the diameter to be used when cutting, and make a markup: place the disk so that its edges do not cling to the casing, and mark the center.

- Cut a square hole in the side of the bottle with a stationery knife.

- You should also cut 2 holes opposite each other, in the place where you marked the center.

- Screw the dust collector to the grinder, using the standard holes for fastening the casing, and put a hose from the vacuum cleaner on the neck of the bottle.

- Put the cutting disc on the angle grinder shaft.

- The hole, which is used for convenience when replacing the tool, can be closed with a small piece of plastic.

After these simple steps, a grinder can be used to process materials, cutting of which creates a lot of dust.

/rating_on.png)