Troubleshooting stinol refrigerators

Refrigerators of the domestic Stinol brand with Italian origin are reliable appliances of the European level with excellent characteristics. Users have noted for these household appliances such distinctive features as high-quality assembly, reliability, durability and democratic price. Despite the fact that the devices of this brand are no longer being produced, Stinol units are still working in many Russian families. But even with careful operation over time, there are various malfunctions at the refrigerator Stinol. In this review, we consider the difficulties faced by the owners of different models of these kitchen units.

Content

Features of the device

Refrigerators of this brand consist of a standard rectangular metal cabinet with a built-in internal chamber. The freezer is made from durable polystyrene. Between the two blocks filled with polyurethane foam, which is a powerful insulating material. Capillary pipeline performs the role of throttling device. Thanks to this detail, the refrigerator becomes sensitive to high humidity and dirt.

Depending on the model lineup, 1-2 compressors are installed in the technique, which have a vertical axis of rotation. The item is located in the lower cabinet unit. The device is a coil of steel tube, fixed in metal plates.

Exist two types of evaporator:

- Static device. It is located on the shelves.

- NoFrost system. It is located in a special compartment.

Diagnosis of the refrigeration unit

To find out the possible cause of the failure, it is necessary to carefully inspect the unit for the working condition of the elements:

- check main nodes on parts corrosion, deformation, mechanical damage to components, violation of protective coatings;

- to examine the device for tightness, durability of fastening parts and automation devices;

- Check 3 functional parameters of the device: the temperature in the freezer and near the back wall of the cabinet, power consumption.

Frequent issues with Stinol refrigerators

The entire model line of refrigeration units is distinguished by reliability, functionality and high build quality. However, they, like kitchen appliances of other brands, are not insured against the occurrence of various breakdowns. Consider the typical malfunctions characteristic of the Stinol line.

Cabinet breakage

If the cabinet is faulty, a thin layer of frost accumulates on the static evaporator. As a result, a significant amount of liquid is accumulated in the condensate collection container.

Defects in this state of the refrigerator are explained camera leakage due to:

- rupture or loose seal seal;

- deformation of the structure of the refrigeration unit;

- the presence of gaps between the rubber seals of the door and the surfaces of the freezer cabinet.

Possible faults with sealing rubber are restored using a hair dryer for drying and styling hair with a capacity of 1-1.5 kW.To do this, heat the rubber seal with a hot spray in the place of contact. Then stretch it to change the shape of the part. After manipulation, the door must be closed. The chiller can be used after the seal has cooled. If the protective layer is torn, it should be replaced.

Loose seal seal

Malfunctions of electric circuit and automation elements

Very frequent breakdowns occur with automation devices and electrical circuit components. These include:

- faulty start or thermal relay;

- breakage of the compressor, fan and other components;

- reduced insulation resistance of the electrical circuit;

- malfunction of thermal fuse or defrost heater in the technique with the system “Nou Frost”;

- defect freezer, timer;

- breakage of the evaporator tray heater;

- blockage of small particles in the drainage system.

Elimination of automatics malfunctions in the Stinol refrigerator consists in identifying the defective part, repairing it, and in case of failure to repair the breakdown, replace the part with a new spare part.

Problems with freon

If the refrigerant volume is too high when charging the device, then the temperature in the freezer is less than -18.0C, the cold store is cold; the return tube is covered with condensate or a layer of frost. To normalize the workflow of the device, after a two-hour run-in adjust the dose of freon.

In the event that the filling dosage, on the contrary, is underestimated, the refrigerator is warm and the temperature is reduced by more than -250C. At the same time, frost can partially form on the back wall. Just as in the previous case, it is necessary to dose the lack of refrigerant to the norm.

If occurred refrigerant leak, oily spots appear in these places. The solution to this problem is to charge the unit with refrigerant or to replace the assembly component with a new part.

A warning! Refrigerant vapors are poisonous gas, so it is taken from the refrigerator special to the cold receivers. After any work with the refrigerant, the room is ventilated for at least 15 minutes.

Signs of problems with the refrigerator and possible malfunctions

There are several typical breakdowns of Stinol units, which manifest themselves in certain ways. In the table we consider the main problems with refrigerators of this brand, and how they appear:

| Sign of | Possible defect |

| The device does not turn on | malfunctioning electrical plug or power cord;

breakage of compressor windings; thermostat or start-up relay does not function; open circuit fuse; jamming timer in defrost mode; a contact failure occurred in the wiring connection due to oxidation |

| After a short operation, the unit turns off | breakage of electric motor starting winding;

the bimetallic plate of the protective relay or the coil of the starting relay does not function |

| The device is slightly freezing | temperature control does not work;

rubber seal lost its elasticity and shape; compressor reduced performance; a blockage of the capillary pipeline or filter dryer occurred; integrity of electrical circuits is broken |

| The fridge is too cold | quick freeze button;

thermostat knob not adjusted |

| The freezer is freezing, and the second chamber is not. | refrigerant (freon) leakage occurred;

depressurization of the system |

| Inside the freezer is warm (refrigeration unit without a system NoFrost) | broken motor-compressor for freezer |

| Moisture is collected at the bottom of the device. | violation of the position of the tube;

debris in the discharge tube |

| Inside the freezer is warm (equipment with the system Nou Frost) | Defect of the automatic defrosting system NoFrost |

Consider the most particular faults of some models.

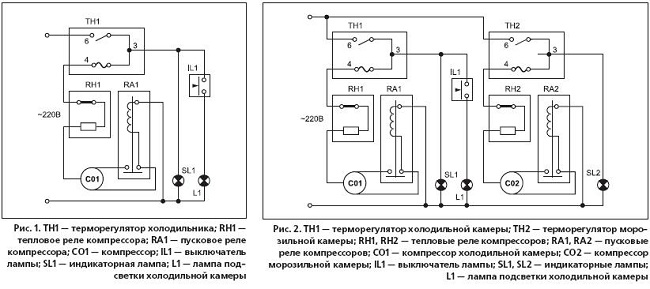

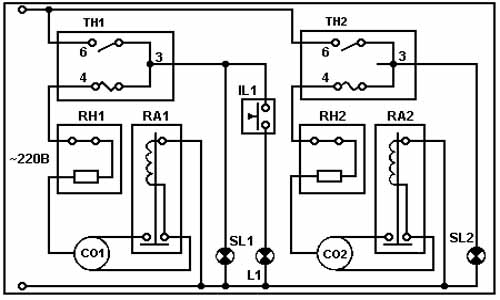

- Two-chamber refrigeration unit Stinol 102. The device has two compressors with a unique system of defrosting the NoFrost freezer. The front panel is equipped with two thermostats. A feature of the model is the air circulation between the freezer and the edges of the evaporator due to the electric fan. Frequent breakdowns of the equipment include a malfunction of the thermal relay (in the TH1 or TH2 circuit). To make sure that the part is faulty, it is necessary to remove the wires from the contacts numbered 3, 4 and short-circuit them with each other. If after the manipulation the compressor starts up, there is a breakdown in the relay. It may be that the equipment does not cool when the compressor is running when the condenser is cold. In this case, there may be a freon leak.

- Stinol 103. The refrigeration apparatus of this model is a typical problem - the failure of the temperature controller.This is due to the technical characteristics of thermoelements, which are designed for a five-year service life. Because of this defect, the temperature in the two chambers may be overestimated, as a result of which the unit will behave unstably. Over time, wiring connections may be broken due to oxidation or burning of contacts, various breaks and other breakdowns. If the starting or thermal relay fails, the compressor does not turn on.

- Stinol 110 - the most common model. Refrigerators consist of a spacious refrigerator compartment and a small freezer, which is equipped with a NoFrost system. Typical failure of this unit is no different from the faults of the 102nd model. The temperature controller T1, timer TIM-0 may be faulty.

Thermostat check

The temperature regulator often fails. This is due to the fact that the thermostat of the German company Ranowhich were installed in the refrigerator, a small working resource is about 5-6 years. If the temperature regulator is not working, the compressor will not start in the refrigerator. To exclude other breakdowns, it is necessary to check the serviceability of this part.

At home, it is difficult to check whether the device is working or not.However, there are 2 ways to determine the working status.

- Regulator contacts under the numbers 3 and 4 (in the diagram of the 103rd model, they are designated as TH 1 or TH 2) must be closed. This maintains the integrity of the electrical circuit and the supply voltage to the input of the compressor (in the circuit CO 1 or CO 2). It is necessary to determine whether the supply voltage to the contacts of the regulator. If it is not there, then the integrity of the entire circuit is checked from the electrical outlet, if there is, the power is turned off and the contacts are called. If they break, the part must be replaced.

- You can also close the jumper thermostat input contacts. If the compressor is working, then the regulator is faulty. Otherwise, the failure occurred not with him. The fault is also determined by ear: when a mechanical turn of the thermostat switch, a click occurs. If not, then there is a high probability of a part malfunction

Any malfunction of the refrigeration unit, whose life is more than 10-15 years, require careful inspection by a specialist. Repairing Stinol refrigerators often involves replacing a worn part.If you buy high-quality original parts and have experience in electrical work, you can replace the spare part with your own hands. If breakdowns occur too often, you should consider buying a more modern version of the refrigeration unit.

/rating_off.png)