Main printer breakdowns

Basically, all faults in the printer, regardless of its model and printing method, occur due to improper operation or due to wear of the main modules of the device. Of the entire mass of breakdowns, due to which office equipment ceases to operate normally, we can single out the most frequently encountered ones related to different types of printers.

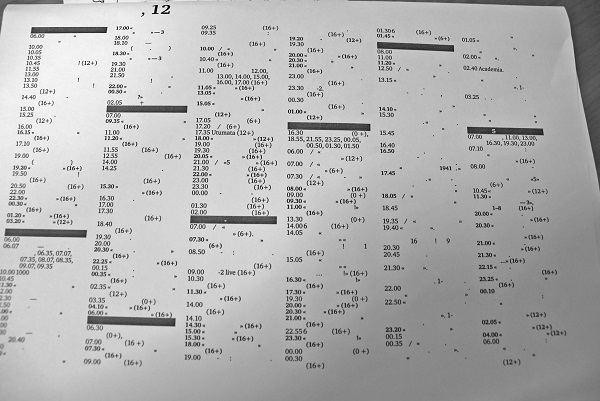

Content

- 1 Dot matrix printer breakdown

- 1.1 The printer does not turn on

- 1.2 The device turned on, but does not print

- 1.3 The machine pulls a lot of paper

- 1.4 Rattle is heard during device initialization

- 1.5 The machine does not pull the paper

- 1.6 The unit crumples the paper

- 1.7 Software errors

- 1.8 The print head goes to the side

- 1.9 Light seal

- 1.10 Prints incomprehensible characters

- 1.11 Fuzzy print

- 1.12 Stripes appear when printing

- 2 Inkjet printer faults

- 3 Typical damage to laser printers

Dot matrix printer breakdown

Despite the abundance of inkjet and laser devices for printing, dot-matrix printers have been successfully used in offices and institutions to this day, thanks to their reliability and low price for consumables. But they, like any office equipment, break for quite common reasons for this type of device.

The printer does not turn on

If the machine refuses to turn on, the network indicator is off, and the print head is in place, this does not mean that the printer has crashed. Basically, this trouble can appear for such reasons.

- No voltage in the outlet. To test, connect to it any electrical appliance (iron, desk lamp, etc.). If the devices do not turn on, it means that there are either malfunctions in the outlet or a complete outage of the building has occurred.

Voltage Test with Other Appliances

- Malfunction of the appliance electrical cable. It may be damaged either near the electrical plug itself or at the entrance to the device. You should also check the plug itself, if it is collapsible.

- Out of order switch. The breaker mechanic itself can break down, or the wires connected to it can be soldered off.

- Blown fuse. Occurs either due to the appearance of internal malfunctions of the device, or due to a voltage surge in the power grid.

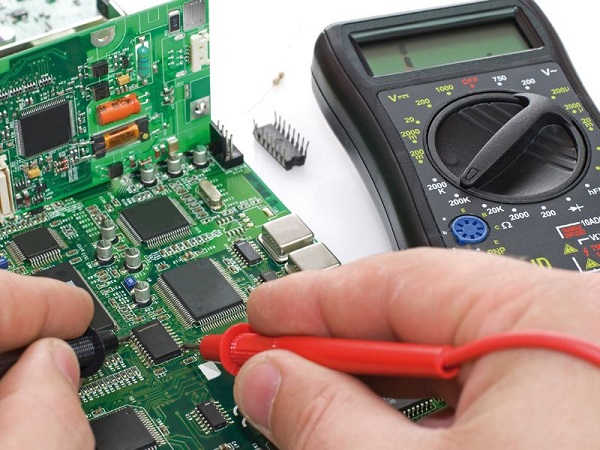

- No current is flowing from incoming circuits.. Lack of voltage can cause breakage of the transformer or stabilizer components. To accurately diagnose the cause, a “dial in” of the input circuits with a multimeter and inspection of the electronic board will be required.

The device turned on, but does not print

The following factors may cause this situation.

- Controller breakdown. Basically, memory chips or a signal processor are burned out. Less frequently, other controller components burn out.

- Damage to the data loop or broken contacts. It is necessary to check the connection points of the cable with the controller and the print head, as well as between separate elements.We can not exclude the fracture of the train in any place.

- Blown electric motor. An electric motor is used to move the print head (PG), in the windings of which a short circuit sometimes occurs. It is necessary to remove this part from the apparatus and ring the windings for a short circuit.

- Out of action PG. The problem is solved only by replacing this part with a new one.

The machine pulls a lot of paper

The fact that the machine pulls extra paper is a fairly common problem for dot-matrix printers, especially if media is used in rolls. This fault is caused by software failures. It is necessary to update the device drivers and check the software from which the document is printed out for errors (sometimes you have to reinstall the program).

Also, the machine can pull a lot of paper due to its incorrect size, or due to incorrect use of the parameter responsible for the translation of pages.

Rattle is heard during device initialization

When the device is turned on, all its components should be initialized and the PG should be moved to its original position.If this process is accompanied by harsh sounds and grinding, then the causes of noise may be as follows.

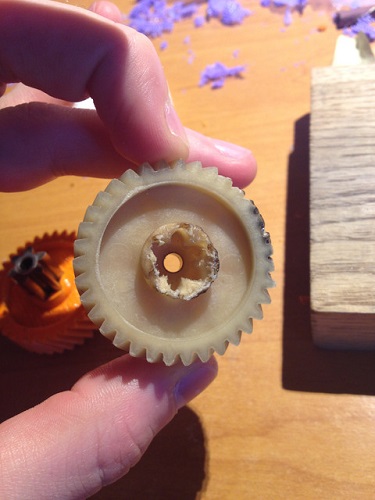

- Breakdown of one or several gearsinstalled in the motor mechanism. The head moves due to a rubber cord having protrusions that moves in the required direction through a block with gears. And since the latter are made of plastic, the teeth on them break or grind. When worn gears interlock with each other, you hear a loud grinding sound and you observe an uneven (jerky) movement of the print head.

- Malfunction in the stepper motor.

- Guide plate damaged. On damaged areas, the GHG slows down, as a result of which the locked gears scroll by the engine continuing their work.

The machine does not pull the paper

Often the device refuses to tighten the paper altogether, or partially tightens it. This is caused by the following reasons:

- engine burnout;

- Faulty transport mechanism that presses the paper to the shaft.

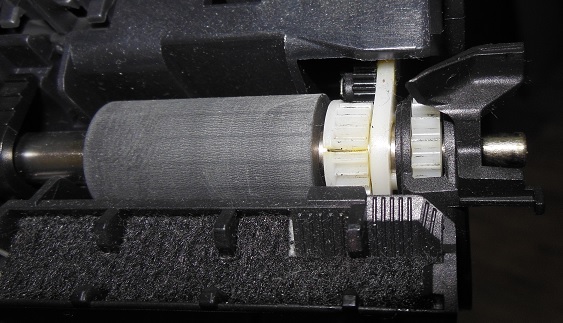

Paper feed roller

The unit crumples the paper

The machine may smother the paper due to the breakdown of the transport mechanism or due to the contamination of the (rubber) rollers in the mechanism. If the machine crumples the paper when printing, this may indicate a poor quality of the media or that the paper is reused. Often, due to improper fixing of the GH of the relative shaft, the paper also collapses.

Software errors

Sometimes during printing, software errors may appear due to the “flew” driver. Also, errors can occur if, in the absence of a “native” driver, compatible software or a device driver of the same company are installed in the system.

The print head goes to the side

It happens that the PG suddenly abruptly goes to the side (more often to the right), and the apparatus stops working. But after turning it off and on again, the device continues to work. With a sharp and noisy movement of PG, “scribbles” are printed on the sheet. Such “jumps” of GHGs are due to unit controller breakdowns. Sharp movements also occur when contact between the SG and the controller is broken.

Light seal

Often, after replacing the ribbon cartridge, lightening may occur. The reasons for clarification may be as follows.

- Incorrectly installed ink ribbon. As a result, it is quickly produced.To check whether the tape is correctly laid, you can use the pen located on the cartridge to scroll it.

- Scroll mechanism does not work. Normally, each time the PG moves, the tape scrolls. This happens in the cartridge with the shaft, on which he puts on. In the case when the shaft is not spinning, the tape remains in place, and the paint on it is quickly depleted, since the GHG passes all the time in one section.

Prints incomprehensible characters

When the controller of the device burns out, then when it is turned on, incomprehensible characters are printed. You can stop the process only by disconnecting the device.

Fuzzy print

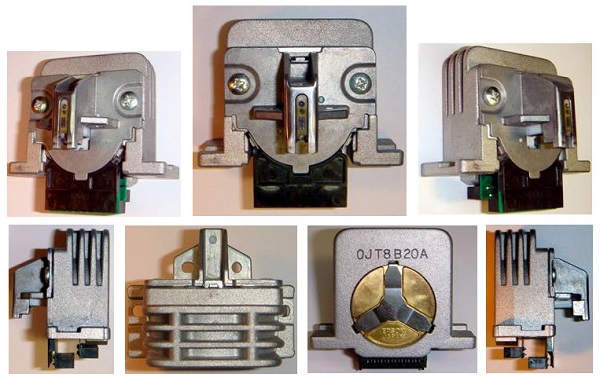

If there are defects in some characters or fuzzy printing, you should check printhead. Such defects can be caused by worn PG, as well as broken needles in it. It is not excluded the failure of electromagnets that control the needles.

Dot Matrix Printhead

Stripes appear when printing

The appearance of light bands in a row can also be caused by the breakage of needles in the PG, both their vertical and horizontal groups, and the failure of electromagnets controlling these groups of needles.

Inkjet printer faults

Inkjet printers are the most popular devices used at home. Despite its popularity, these units are very "capricious" during operation, and refuse to work for many reasons.

The device does not turn on

In a situation where the device does not turn on, the problem may be hidden in the following:

- If you have turned on the unit and there is no light indication on its case, you need to check the voltage in the outlet, the condition of the electrical plug, and the condition of the electrical cable.

- Blown power supply. The printers have an integrated power supply that converts alternating current into direct current with a voltage of 12 V. To test the power supply, you will need to measure the voltage with a multimeter at its outputs. If it is missing, you will have to disassemble the unit and ring the entire chain. Also pay attention to the fuse (if its presence is provided).

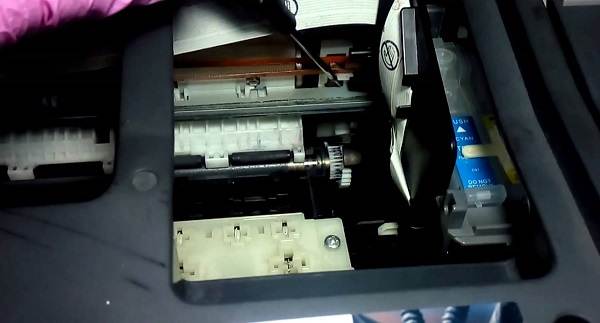

The device crumples the paper

Paper jams most often occur due to clogging of pressure rollers. They need to be cleaned with a gauze pad, slightly soaked in alcohol. In the case when the paper jam is repeated after cleaning and test printing, all the rollers should be checked.Perhaps one of them is stuck.

Also a problem with a paper jam can cause a burnt out electric motor.

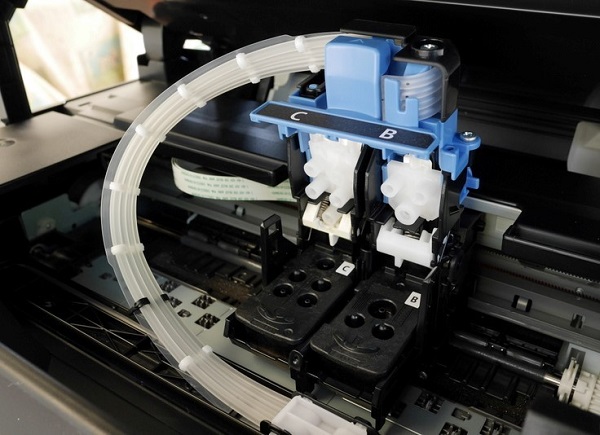

Ink cart does not move

After turning on the printer, the cartridge carriage should start moving. If this does not happen, then maybe engine burned out or separate nodes of the control circuit of the apparatus. In this case, without contacting the service center is not enough.

Light seal

If you notice that the print image has become faded or heavily brightened, then this is a clear sign of running out of ink in the cartridge.. This usually happens when tracking the amount of ink in the ink tank is disabled in the printer when using refillable cartridges. It is necessary to add ink as quickly as possible. Otherwise, the print head may dry out.

The text is twofold

When printing text on a printer doubles, then the problem may be caused by the following reasons.

- When installing the CISC ink trail was laid incorrectly. It complicates the movement of the carriage, violates its positioning.

- Encoder tape dirty. The print head makes its positioning in space with the help of this plastic tape with strokes on it.If the tape is contaminated with dust or dried ink, the sensor cannot position the carriage correctly, resulting in blurred or duplicate images on prints. Elimination of printing defects is performed by cleaning the tape from contamination.

- Pollution guides. If rubbish, foreign objects or ink dried on the guides on which the carriage moves, ink has dried, then the GHG movement will be difficult. It is necessary to remove dirt and lubricate the guides.

Stripes on the print

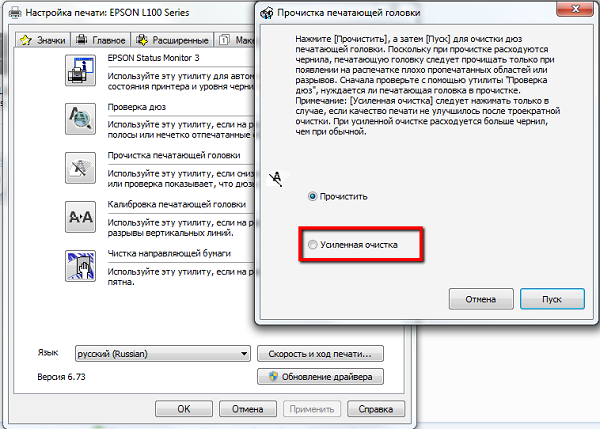

Since the print head consists of a set of thin tubes (nozzles), print defects in the form of light stripes appear because of their blockage. For nozzle cleaning It will be necessary to start a regular GHG cleaning operation using printer facilities. If this does not work, start deep cleaning of the head. For heavily dried nozzles, soaking them and rinsing them with special liquids will be necessary.

Typical damage to laser printers

Since the laser printer is quite complex in technical terms, the apparatus, and the reasons for failures due to the presence of many nodes abound.

The unit does not turn on

About this fault, and how to detect it, mentioned above, when reviewing failures matrix and inkjet printers. This information can also be used with respect to laser devices.

The machine does not print

The reasons that the machine does not print may be the following:

- software errors;

- driver damage;

- failure of the board responsible for image formation;

- the wrong device is selected for printing;

- print queue hung;

- paper jammed or missing;

- problems with the cartridge.

Paper crumples

If the paper is wrinkled during the operation of the laser apparatus, this is due to poor rotation of the soiled rollers, or due to jamming of one of them. The guide bar, if damaged, can also jam the paper. If a paper jam occurs when it leaves the device, then rollers or a guide bar with rollers can be skewed in the output unit.

The image is not fixed

In the case when you notice that the image is easily erased on the sheet that came out of the printer, this means that it is not fixed. There is this trouble, because thermal failure together with guides and thermal film.

Also, the image will not “stick” to the paper, if you install too thick a thermal film.

Vertical black stripe

When a black vertical strip appears along the edges of the sheet, it can be said with confidence that defective druminstalled in the cartridge. The drum can be replaced, and use the cartridge further.

Vertical white stripe

A white bar located vertically may appear when running out of toner. Try pulling out the cartridge and shaking it several times. Print: if the strip has disappeared or moved to another place, then it’s time to carry the cartridge for refueling.

This situation happens when tracking the amount of toner is turned off in the printer or MFP.

Another reason for the appearance of a white stripe may be the clogging of a laser lens or the ingress of a foreign object (a piece of paper, a clip, etc.) under the dosing blade.

Dark prints

The appearance of dark prints is a sign magnetic shaft wear. The problem is solved by replacing this part.

Grinding and creaking during unit operation

Creaking when working with equipment may be caused by paper feed rollers, which must be thoroughly cleaned.All moving parts of the cartridge can also creak, due to their wear or clogging with toner, paper dust. A strong rattle can be heard if the gearbox of the apparatus, which has gears in its structure, fails.

Paper stop

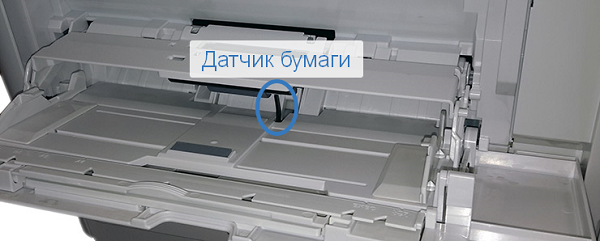

If the sensor controlling the paper output is faulty, it will remain in the printer. Since the sensor is most often clogged with dust and toner, it will require cleaning.

Gray blurred strip

The appearance of a gray strip with blurred edges indicates that the cleaning drum blade does not clean it well of the remaining toner. The cause of poor cleaning may be the ingress of a foreign body under the squeegee, blade wear, overflow of the waste bin.

By the way, the printer often smears also due to clogging of the waste bin.

The problem is eliminated by removing foreign bodies, replacing the blade and cleaning the cartridge.

The paper does not tighten

This problem most often lies in paper tray. Namely, it arises from a crack appearing on the body into which the reverse gear is inserted. This defect breaks the contact between the reverse and the spring. This malfunction is unpleasant in that it is necessary to change the entire tray if the casing is not strengthened.In the case when the rattle is heard and the machine does not pick up the paper, it will be necessary to replace the gear wheels of the unit.

Pale prints

The appearance of a faint print is caused by a malfunction of the unit responsible for image transfer, as well as the wear of the magnetic shaft. In addition, the appearance of pale prints can be triggered by other factors.

- Worth a look in the print settings. You may have set the “print in economy mode” setting.

- Wrong toner selected.

- Dosing blade damaged.

- Worn drum.

- Increased paper moisture. With high humidity media, the contrast is greatly reduced. The higher the moisture content of the paper, the fainter the prints will be.

- In some cases, thorough shaking helps to get rid of the pallor of prints when the cartridge is fully filled. This procedure helps the toner to be evenly distributed inside the cartridge.

Damaged and exited parts of the cartridge that cannot be repaired at home can be replaced and repaired at a service center.

/rating_on.png)

/rating_off.png)