What to do if the printer stops printing in black

The fact that the printer does not print in black color, users of these devices often encounter. This type of problem can be caused by various reasons. They are typical for models HP, Epson, Canon and others. The most serious in terms of repair include mechanical damage to partsFor example, the print head. In such cases, you will need to contact the service center for help. But most of the reasons simply enough to eliminate their own, without assistance.

Content

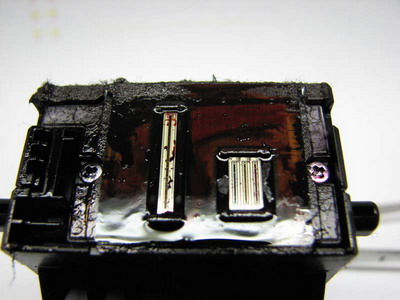

Damage to the print head

Very often it does not print black in the printer due to damage to its print head. To identify this problem is quite difficult.If there are suspicions of this kind, it is better to attribute the device used service center manufacturing company. When confirming damage to the print head, there are two ways to solve this problem:

- replacing the old part with a new one;

- purchase of new printing technology.

But before contacting the service, you need to check other possible reasons to exclude them. This will avoid unnecessary actions and possible costs if the device is not under warranty. Often in this way the question is solved by itself.

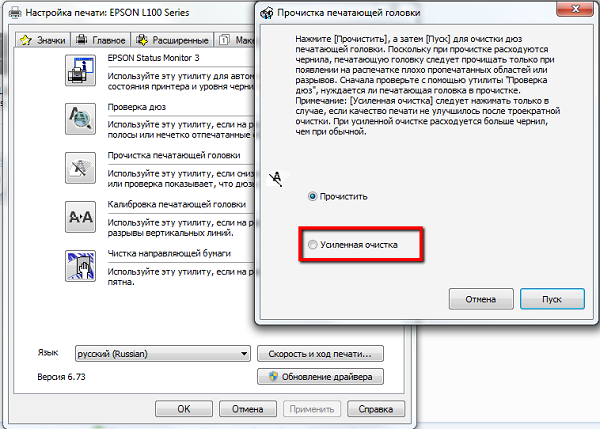

Clogged printhead or dried nozzles

The following common causes for the printer to stop printing in black are:

- printhead clogging;

- paint drying in the nozzle.

Print head clogged nozzles

Cleaning printheads carried out in this way:

- check the level of black ink in the printer settings;

- when available, perform a test printout;

- when it didn’t work, it was washed special solution printhead;

- give time to the composition to act (about 15 minutes);

- go into the settings of the printing device and select the item to clean the heads;

- after the process is completed, perform a test printout of any document.

If the first time did not work, then all actions must be repeated again. When the second attempt did not bring the desired result, then you should do the nozzles. They often dry out with rare use of technology. To remove dried paint from the nozzles, wipe them with cotton moistened with alcohol. Only after drying print a test document.

Upon receipt of a satisfactory result, you can begin to work with equipment. Note that the nozzles and printheads need to be periodically cleaned to prevent clogging or drying of the ink.

The exact timing of regular inspections is given in the instruction manual for each model.

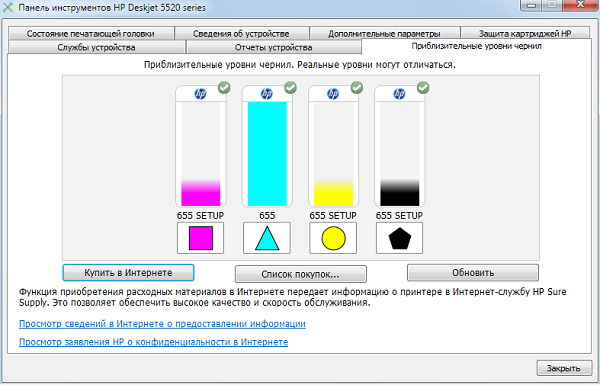

Missing or incompatible ink

The simplest reason for the device to stop printing in black ink is the banal lack of ink. The computer may not notify due to various user failures about the incident. Problem is solved adding ink:

- about 2 cubic centimeters of paint are injected into the cartridge with a syringe;

- conduct testing;

- if the result is positive, you can still add as much paint and print documents.

When performing a refill yourself, remember that in some models it can be performed only after the cartridge is installed in its place in the printer. For the procedure will need a special syringe.

Also, the equipment used may not print in black if the inks used and applied are not compatible with each other. Therefore, before refueling, you should carefully examine the label on the ink jar. Such information is always indicated there.

It is better to purchase consumables from reputable, trusted manufacturers to be confident in their quality.

Replacing a used cartridge with a new one that is suitable for the model used is an even easier way to eliminate this kind of problem. But the implementation of filling their own hands will cost much cheaper.

Substandard refueling

It happens that after adding high-quality black ink, the technique still refuses to print. This may be due to poor-quality refueling: cartridge is incorrectly inserted or sealed. Then the fault is eliminated simply:

- take out the cartridge and reinsert until it clicks;

- pre-or after installation, stick the tape from the needle of the syringe with adhesive tape (duct tape);

- then check the operation of the device.

It is necessary to do all manipulations carefully in order not to accidentally break anything.

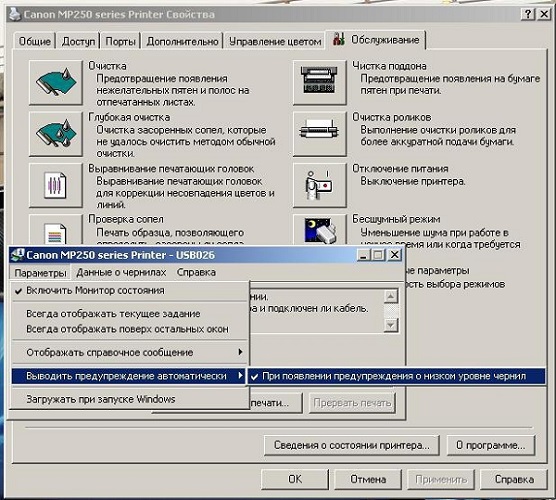

Disable ink control and chip zeroing

A number of models of printing equipment is equipped with a function to control the level of ink. Therefore, when the last ends, the printer does not print in black, it locks up. To fix the problem, you must disable the level control function. Do this in several ways.

- When a message appears that the ink runs out, then press the button responsible for feeding the paper, hold it for at least 10 seconds.

- You can enter the printer’s menu on the computer, select the “properties” tab there, deselect the item allowing two-way data exchange, confirm the actions.

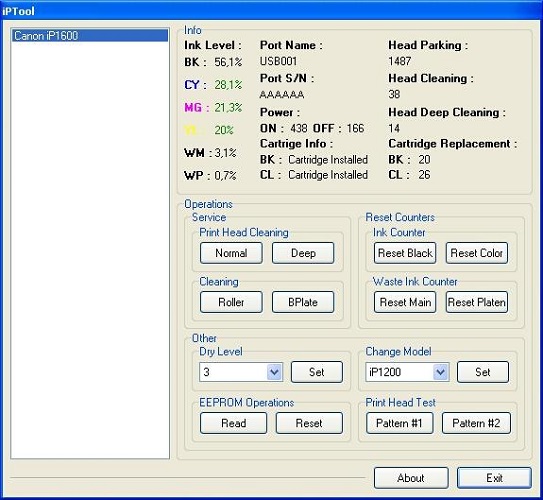

- For individual models, special programs are installed that reset the ink consumption counter, for example, iptool and mptool.

- Zero the chip on the cartridge.

Zeroing is recommended after self-refilling. To do this, use the programmer (resetter).You can also purchase disposable or automatically zeroable compatible chips that work on some models.

It should be remembered that self-stopping the ink level control function removes the device from the warranty.

There is a less expensive way to reset the cartridge count - for this stick the corresponding contacts. The problem of practical implementation lies in their finding. Different models of cartridges use different contacts. The action algorithm is as follows:

- include equipment;

- take out a black ink cartridge;

- put it on the table, pointing it towards you with nozzles, and pointing it up with contacts;

- stick the left upper contact with scotch tape;

- insert the cartridge, click "OK";

- print out the verification document;

- get the cartridge back;

- stick any contact on the bottom right;

- install a cartridge in the socket;

- check equipment performance;

- remove the cartridge and peel off the first contact;

- insert it back, awaiting recognition;

- then take out the cartridge and remove the second tape;

- wipe all the contacts with cotton moistened with alcohol;

- return to the place.

After the done manipulations, the ink identifier should show 100% of their level. If this does not happen, you can try to seal the second time instead of one lower right contact 3 upper. All further actions are carried out similarly.

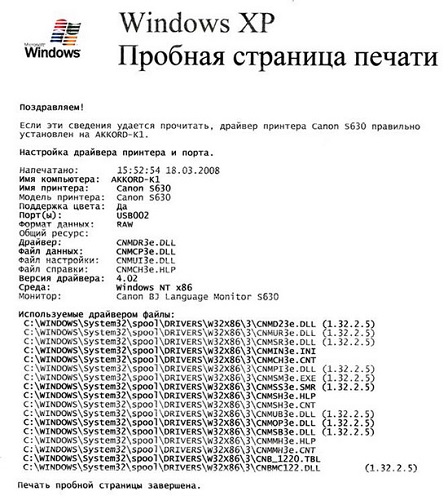

Driver problems

Independently at home you should check the operation of hardware drivers. When doing so:

- reinstall the corresponding programs;

- print a trial text.

The persistence of the problem after all the reviewed activities indicate a more serious breakdown. If the equipment is under warranty, then it is necessary to contact it at the service center or the store where the goods were purchased.

In order for the equipment to serve for a long time, you should regularly clean the printheads and nozzles. Compatible, high-quality inks should also be used. If the equipment is idle, then once a month it is required to print out any document to prevent ink drying. It is recommended to use by several cartridges of each color, then after refilling they will be perceived as new.

/rating_off.png)