Functions of the safety valve in the boiler

Not only the duration of its operation, but also the level of safety during operation will depend on the quality of the strapping of the electric storage water heater. This is one of the most serious moments when installing a boiler that requires special attention. Correct strapping for a water heater, a safety valve is incorporated into the cold water supply system.

Content

Main purpose

Embedding the safety valve protects against a sharp increase in pressure in the internal part of the unit, which is much higher than normal. The question arises, what is the reason for such a jump? As it was possible to establish, during heating the liquid increases in volume, and, therefore, expands.Due to the tightness of the heater tank, the resulting surpluses simply have nowhere to go - the valve is closed (as a rule, a check valve is installed for the supply).

Further heating of the fluid may result in pressure increase. At this moment, there is a danger of exceeding the strength of the unit and breaking its walls. To avoid such an explosion, a safety valve for the boiler is installed.

Some owners may ask: is it worth suffering with installing a fuse when you can simply remove check valve. Experts respond to this as follows: with relatively high and uniform pressure in the water supply system, such a scheme will function, but for a while. This does not mean that such actions are the way out. The fallacy of this scheme is due to a number of reasons:

- The pressure in the water supply system is not stable.

- Excess water is removed from the boiler to the water supply, exposing the heating element.

- Heating the air, the boiler after some time will fail.

Blown heaters are not the biggest problem.More importantly, there is the danger of a sudden change in pressure in the water pipes. Liquid, getting on the heated heating element, quickly turns into steam, sharply increasing pressure. Under such conditions, the walls of the boiler are guaranteed to burst. A large amount of boiling water and steam, pushed by pressure, will fill the room, threatening all with serious injuries.

Principle of operation

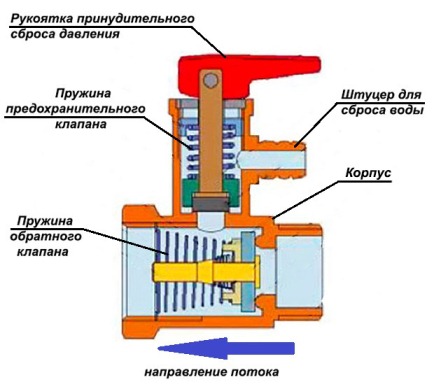

The safety valve for the water heater in addition to the basic structure consists of several more elements. They are located in a brass or nickel housing. In most cases, the device looks like an inverted letter T. To the bottom of the tank on the water heater is attached check valve, able to prevent leakage of fluid from the reservoir, with a drop in pressure in the pipes.

The perpendicular branch holds one more valve, which is activated after the increase in pressure and discharges excess fluid through the nozzle. The principle of operation occurs in several stages.

- If the pressure of the reservoir is lower than that occurring in the pipes, the disc plate in the check valve is pressed by water pressure when filling or opening the valve.When the pressure level returns to normal, the spring mechanism presses the plate against the protrusion of the body, restricting the flow of fluid.

- During active heating, a slow increase in the temperature of the liquid occurs, and with it increases the pressure. Until it reaches the maximum value, the mechanism is not activated.

- After reaching the limit, the pressure squeezes the spring of the fuse, opening choke output channel. Excess fluid from the reservoir is removed through this channel. After reducing the pressure to the normal level, the spring closes the channel, and the removal of water stops.

Based on the above, it can be understood that the fluid from the choking channel will periodically drain. This phenomenon occurs during water heating and pressure reduction in the water supply system. If you regularly notice water at the chokeThis means that the safety valve for the boiler is operating normally.

However, along with this, there is a need to divert the flowing liquid. For the implementation of the procedure on the pipe is fixed tube of a suitable size: it is necessary pull off the yoke to ensure a secure fit.The nominal operating pressure in the tank of the heater is from six to ten bar. Without securely fastening the tube will simply rip off, therefore, the choice of the clamp must be approached with special care. Tighten it firmly and bring the tube to the nearest sewer drain.

The tube at the nozzle should be transparent, the reinforced hose would be an ideal option. This helps control the performance of the system, and reinforcement provides additional protection against pressure.

Valve principle

Features of various types of valves

If we talk about the standard safety valve for the boiler, they are not very different in appearance. However, there are small nuances that are responsible for the usability of the device.

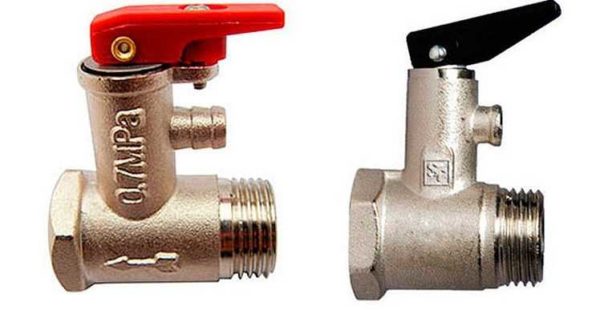

Release lever

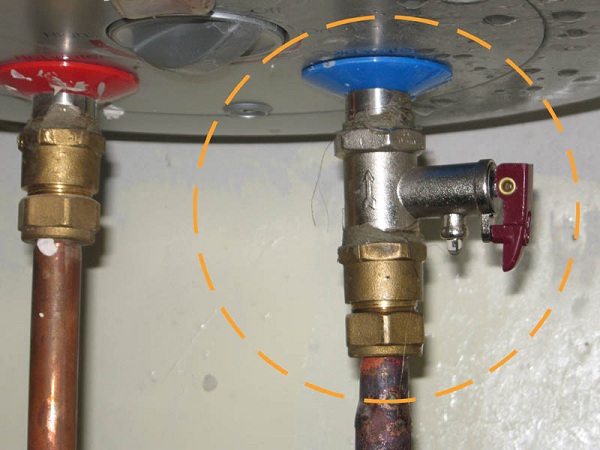

The image shows valves equipped with trigger levers. Their purpose in periodic health checks:

- the lever is transferred to the vertical position;

- it activates the spring mechanism, dragging it down behind him;

- eventually a duct opens, through which water flows.

Trigger on valve

This procedure is recommended at least once a month.In the same way, complete dewatering of the tank of the heater is carried out. After raising the flag, you must wait for some time until it drains completely.

The differences in the models shown are that the valve on the left has a lever that is fixed special bolt. This eliminates the possibility of involuntary opening and complete removal of fluid.

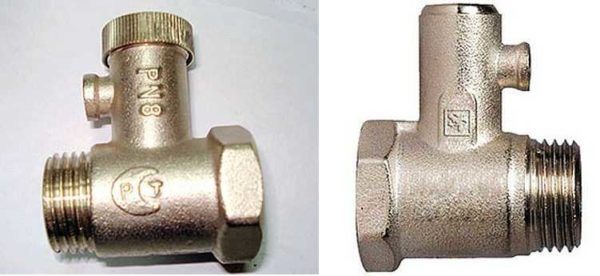

The following image shows the valves without the lever for the forced removal of fluid. The left model has a cap fastened to the threads in the upper part. It is intended for maintenance of fuses. If necessary, it is unscrewed to remove blockages, scale and other contaminants.

Valves without lever

The right model is the least preferred option. It does not have any markers, a water release lever, or a service hole. This is the cheapest and lowest quality product supplied from China. Talk about reliability and durability is not necessary. It can be used only as a temporary replacement at your own risk.

Pressure Mark Remark

There are some more noticeable differences. The arrow shown on the box indicates water flow directions, as well as the inscription indicating maximum pressurewhich is able to withstand the device. At first glance, the details seem insignificant. But if it is easy to understand the direction of fluid flow (it’s enough to look at the location of the poppet type valve), then the situation with nominals is more complicated.

On what grounds can the valve be distinguished by six and ten bar? Only by experience. You ask, how do suppliers differentiate them? No, only on the inscriptions in the documents. Experts do not recommend purchasing devices without any signs on the case. Of course, the cost of labeled products may be higher than that of counterparts, but in this matter it is better not to save.

Fitting Form

In addition, you should pay attention to the shape of the nozzle for removing fluid. In the left model, this element is rather long, has non-linear by form. It will be easy for him to attach the tube, and the length is quite enough to secure the clamp.

The shape of the similar element in the right model is different. It has a characteristic extension at the end, but the most important thing is the length of the nozzle.It will be quite difficult to install a tube on it and even harder to provide a secure fit. The use of artisanal methods will not be able to guarantee a good result, and in the future there may be difficulties with wastewater disposal.

For high volume boilers

Each of the devices described above is intended for an accumulative water heater with a volume of fifty to sixty liters. Other systems are used for larger tanks, and special systems are integrated into each of them. Most often this ball pressure gauge or pressure control tap.

Ball pressure gauge

A fitting for the removal of fluid in them is equipped standard thread to increase the reliability of fastening and solve problems with clamps. This type of device has a high price, but the quality level significantly exceeds other systems.

A significant disadvantage for many owners may be the appearance of the crane. Especially for such people, production of fuses has been established, bringing not only practical use, but also those capable of decorating the interior of a room. Their cost can significantly reach the price of the boiler itself, so everyone will evaluate the feasibility of such a purchase.

Installation of other valves

There are cases when instead of the factory system of protection against pressure surges on the heater tank it is set blast valve. It is intended primarily for emergency removal of fluid into the heating system. Although their functionality largely converges, the basic principle of operation is fundamentally different.

A subversive valve performs its functions only during an accident. It is needed for emergency removal of all water from the tank. It is not intended for periodic bleeding of small portions of liquid. Given all this, you should not wait for the correct functioning of such crafts.

Another example is mount only check valve type. Its mechanism will not allow liquids to flow under reduced pressure in the system, but it cannot save them from sudden surges in the tank. As practice shows, such an assembly is also not functional.

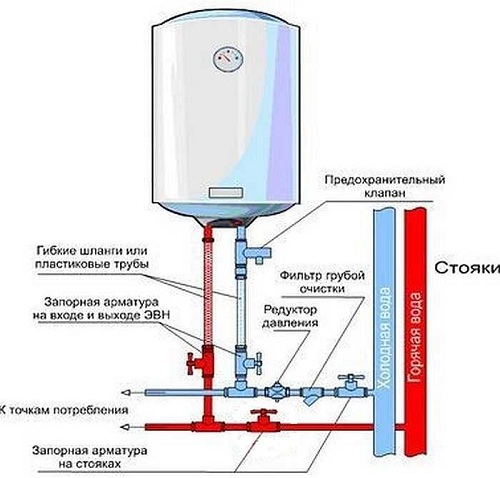

Diagram of all components of safe operation of the heater

Selection and installation

Choose a fuse should be based on the pressure indicators that the device is able to withstand. This figure is usually made in the data sheet. In addition, the volume of the tank can affect the choice.There are systems with a threshold of six, seven, eight, ten bar. These are the most common values for triggering a fuse.

The installation process is quite simple.

- Wind a special tape or linen tow onto the thread for tightness.

- Screw the valve onto the nipple.

- Continue to tighten it all the way with your hands, and then make a few turns with the key.

- Do not forget about the correct choice of place for its installation. Experts recommend attaching it directly to the inlet pipe for cold water.

After that, you can install a check valve system, or as they call it - constipation. But these are reinsurance measures, a device with similar functions is already included in the fuse system, and it is often integrated into water meters.

The diagram shows ball valve arrangement. It is used to remove fluid from the tank during preservation for the winter or during dismantling. Drainage may also be required during maintenance or repair. In most cases, it is installed on the tee, which, in turn, is connected to the fuse system.

You should not save on such an important detail as a fuse.This device will help you not only keep the heater working, but also, possibly, save you from serious injuries. Pressure surges in the water supply system are not uncommon, and no one is insured against the failure of the reservoir. Spend some time installing safety valves and be assured of your own safety.

/rating_off.png)